الوصف

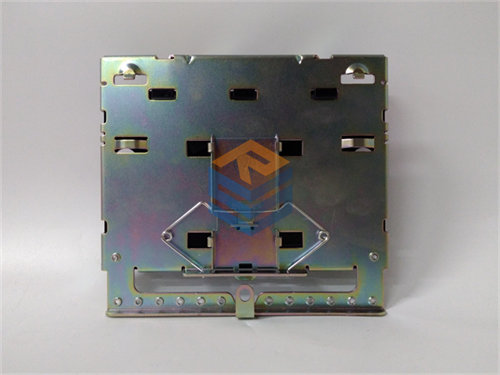

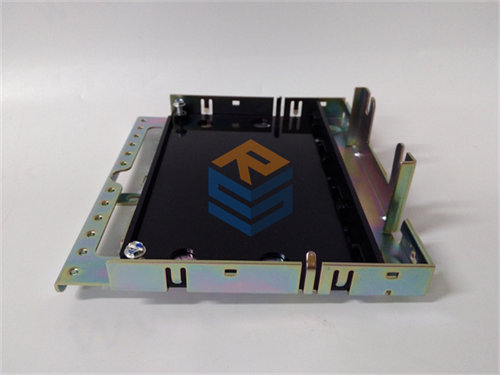

The GE IS230TNAOH2C is a DIN rail-mounted I/O module assembly for the GE Mark VIe control system. The part number indicates that it is a pre-packaged assembly of a TBAOH1C terminal board and a PAOCH1B I/O module. This unit is designed to provide analog output signals.

Key Features

- Analog Output: The main function of this assembly is to provide continuous analog output signals, typically a 4-20 mA current or a 0-10V voltage. These signals are used for precise control of field devices like valves and actuators, allowing them to be set to a specific position or flow rate rather than a simple on/off state.

- Assembly: The part number shows that this is a ready-to-install unit composed of two main components:

- TBAOH1C: The Terminal Board is where the physical field wiring for the analog outputs is connected.

- PAOCH1B: The I/O Module is the electronic component that converts the digital command from the controller into the physical analog signal.

- DIN Rail Mounting: The assembly is designed for standard installation on a DIN rail, which is a common practice in industrial control cabinets. This simplifies wiring, saves space, and makes installation and maintenance more efficient.

- Mark VIe Integration: As part of the IS230 series, this assembly is designed to seamlessly integrate with the Mark VIe control platform, a system widely used for controlling turbines in power generation plants.

Applications

The IS230TNAOH2C is used in a wide range of industrial settings that require reliable and precise analog control.

- Power Generation: It’s used in power plants to control fuel flow, turbine speed, and the position of various valves to maintain stable and efficient operation of gas and steam turbines.

- Industrial Automation: It is a fundamental component in many manufacturing processes that rely on automated control for efficiency and product quality, such as regulating the flow of a fluid in a chemical plant or controlling the speed of a motor in a production line.

- Oil and Gas: In refineries and offshore platforms, it controls the position of critical valves to regulate flow, pressure, and temperature.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922