الوصف

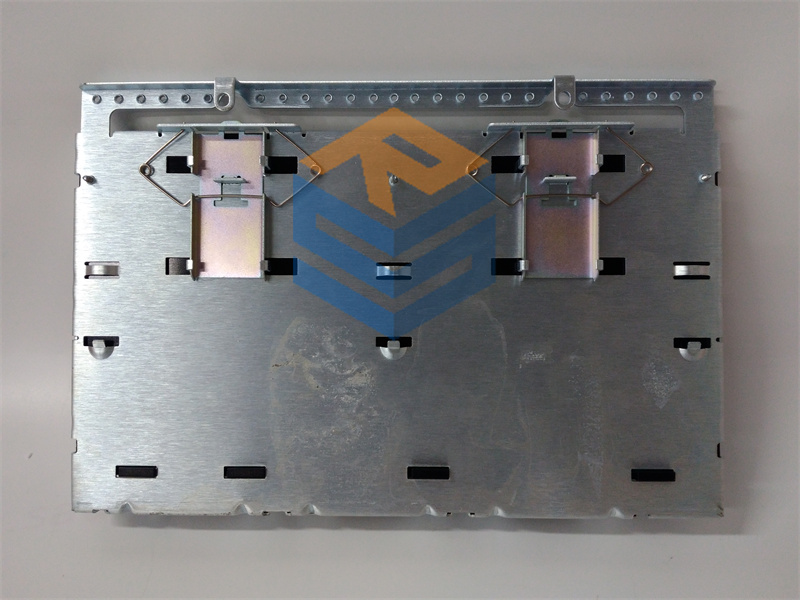

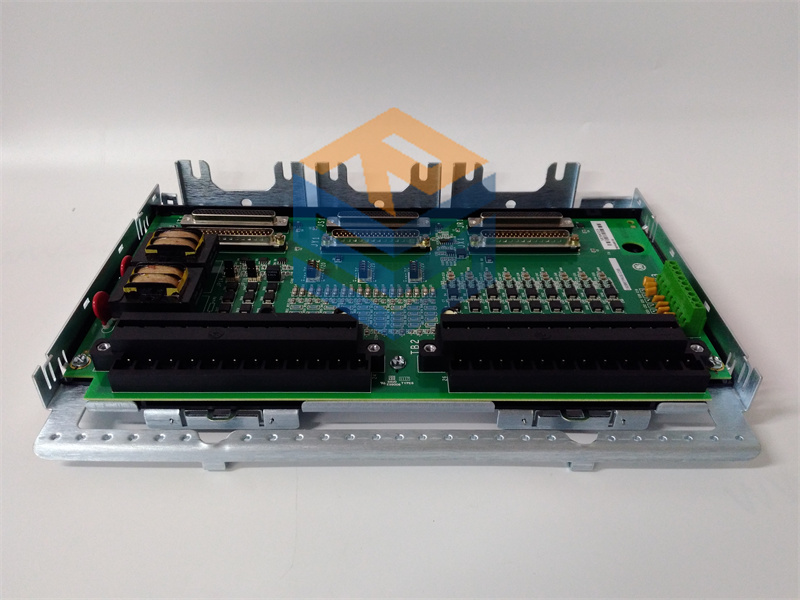

The GE IS230TNRLH1E is a DIN rail-mounted layout module for the GE Mark VIe control system. The term “layout” indicates that this is a specialized terminal board used for a specific wiring arrangement, but it does not contain the electronic I/O processing circuitry itself.

Key Features

- Layout Module: This component is a terminal board with a specific design or arrangement for connecting field wiring. It provides a clean and organized termination point for signals from sensors and actuators. It is not a complete I/O module but a physical interface that works in conjunction with a separate electronic I/O pack.

- DIN Rail Mounting: The board is designed for standardized installation on a DIN rail, which is a common practice in industrial control cabinets. This simplifies wiring, saves space, and makes the system modular and easy to maintain.

- Mark VIe Integration: As part of the IS230 series, this board is a key component of the Mark VIe control platform, which is widely used for controlling turbines in power generation and other heavy industries.

Applications

The IS230TNRLH1E is used in a wide range of industrial settings to provide a reliable and organized interface between the physical process and the control system.

- Power Generation: It is used in power plants to connect the extensive wiring from various sensors and devices on a gas or steam turbine to the control system, ensuring a clean and manageable installation.

- Industrial Automation: It is a fundamental building block in automated manufacturing processes that require precise and reliable control.

- Oil and Gas: In refineries and offshore platforms, it provides a stable and organized connection for the wiring of pumps, valves, and other critical process equipment.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922