الوصف

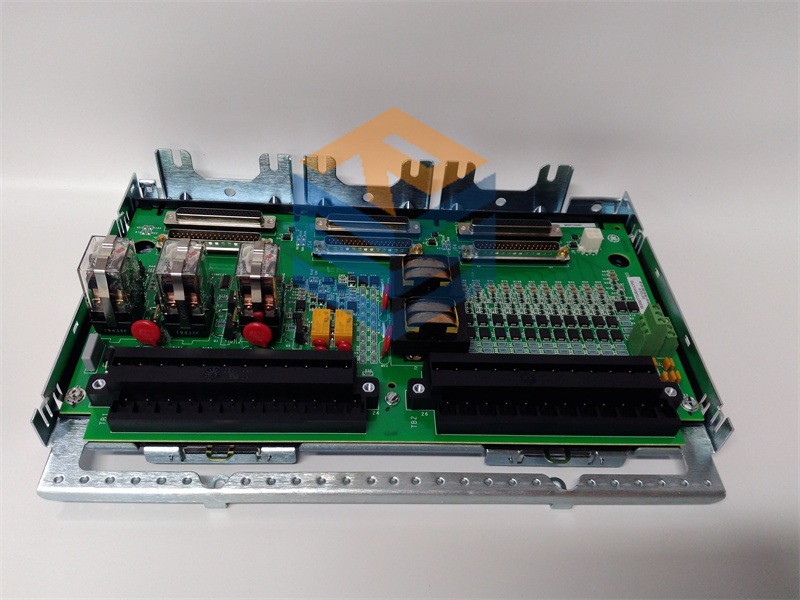

The GE IS230TNRTH3D is a triple-modular redundant (TMR) I/O module assembly for the GE Mark VIe control system. The part number indicates a specific assembly that includes the TRTDH1D terminal board and two PRTDH1B I/O packs at the R and S locations, making it a redundant system for thermocouple or RTD (resistance temperature detector) inputs.

Key Features

- TMR (Triple-Modular Redundant): This module is configured for high reliability. While the part number mentions two I/O packs (R and S locations), it’s part of a TMR system where three I/O packs work together to provide fault tolerance. A voting algorithm compares the temperature readings from the inputs, allowing the system to continue operating and provide accurate data even if one or two modules fail. This redundancy is critical for high-availability and safety-critical applications.

- Thermocouple/RTD Input: The assembly is designed to read low-level analog signals from thermocouples and RTDs, which are common sensors used to measure temperature in industrial processes.

- Assembly: The part number signifies a complete, ready-to-install unit, consisting of both the terminal board (TRTDH1D) where the temperature sensor wiring is terminated and the electronic I/O packs (PRTDH1B) that process the signals.

- Mark VIe Integration: As part of the IS230 series, this assembly is designed to seamlessly integrate with the Mark VIe control platform, a system widely used for controlling turbines and generators in power plants.

Applications

The IS230TNRTH3D is used in industrial settings where the precise and reliable measurement of temperature is critical.

- Power Generation: It’s a fundamental component in turbine control systems to monitor temperatures in critical areas like combustion chambers, bearings, and exhaust systems. The TMR configuration ensures that a temperature sensor failure won’t lead to a loss of control or an unnecessary turbine trip.

- Process Safety: This module is often used in safety-critical systems where an out-of-range temperature could indicate a dangerous condition, triggering an alarm or a safe shutdown.

- Oil and Gas: In refineries and offshore platforms, it’s used to monitor temperatures in compressors and other critical process equipment, where the TMR configuration ensures continuous and reliable operation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922