الوصف

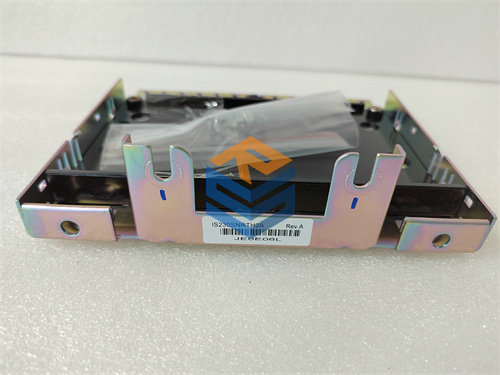

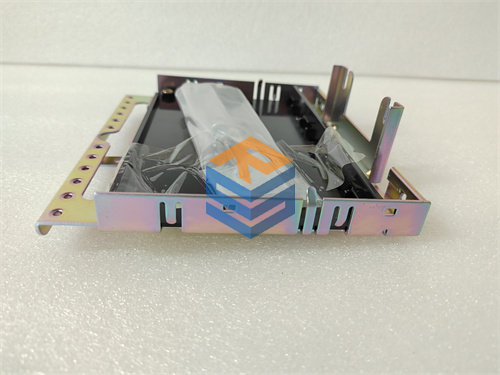

The GE IS230TNSVH1A-XA is a simplex servo control assembly for the GE Mark VIe control system. The “XA” in the part number signifies that the module is certified for use in potentially explosive atmospheres as per ATEX standards. This assembly is designed to provide precise, non-redundant control of servo valves in hazardous locations.

Key Features

- Servo Control: This assembly is specifically designed to control servo valves, which are used for the precise, continuous positioning of actuators. Unlike a simple on/off valve, a servo valve can be commanded to be at any position between 0% and 100%, allowing for fine-tuned control of a process.

- Simplex Configuration: The term “simplex” means there is a single, non-redundant control channel. This is a common and cost-effective approach for applications where a single point of failure won’t lead to a catastrophic event.

- ATEX Certification: The “XA” signifies that the module has been certified for safe operation in hazardous environments where flammable gases, vapors, mists, or dust may be present. This is a critical requirement in industries like oil and gas and power generation.

- Assembly: The part number signifies a complete, ready-to-install unit, consisting of both a terminal board and an electronic I/O pack that processes the signals.

- Mark VIe Integration: As part of the IS230 series, this assembly is designed to seamlessly integrate with the Mark VIe control platform, a system widely used for controlling turbines in power generation plants.

Applications

The IS230TNSVH1A-XA is used in various industrial settings that require reliable and precise analog control in hazardous locations.

- Power Generation: It is used in power plants to control the position of various valves to regulate fuel flow and turbine speed, ensuring stable and efficient operation of gas and steam turbines. The ATEX rating is essential for applications involving natural gas.

- Oil and Gas: In refineries and offshore platforms, it controls the position of critical valves to regulate flow, pressure, and temperature. The ATEX certification is a crucial safety requirement in these environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922