الوصف

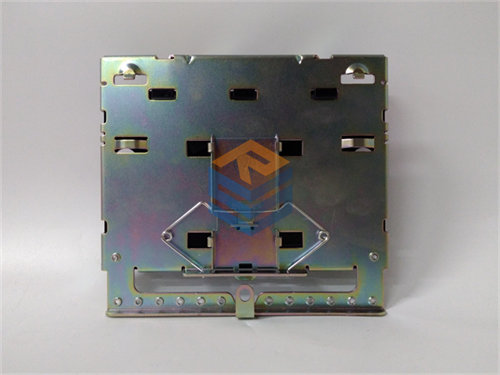

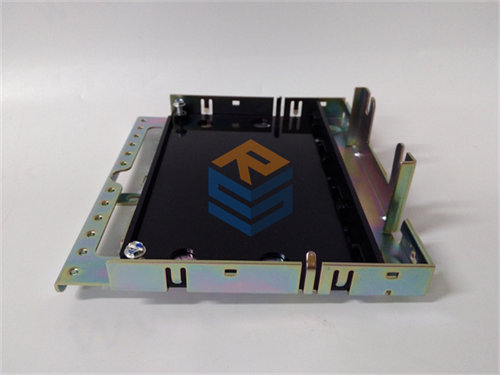

The GE IS230TNSVH1A-XA is a simplex, ATEX-certified servo control assembly for the GE Mark VIe control system. The “XA” suffix indicates that the module is certified for use in potentially explosive atmospheres. This pre-configured assembly is designed for precise, non-redundant control of servo valves in hazardous locations.

Key Features

- Servo Control: The module’s primary function is to send continuous, high-resolution analog signals (typically current or voltage) to precisely control the position of a servo valve. These valves are critical for dynamic control of hydraulic actuators, which position turbine valves and other essential machinery.

- Simplex Configuration: The term “simplex” means it has a single, non-redundant I/O channel. This is a cost-effective choice for applications where a single point of failure won’t lead to a catastrophic event.

- ATEX Certified: The “XA” signifies that the module meets the safety standards for operating in hazardous environments where flammable gases, vapors, mists, or dust may be present. This is a crucial safety requirement in industries like oil and gas.

- Assembly: The part number denotes a complete, ready-to-install unit, including a terminal board and the electronic I/O pack.

- Mark VIe Integration: As part of the IS230 series, this assembly is a key component of the Mark VIe control platform, which is widely used for controlling turbines in power generation.

Applications

The IS230TNSVH1A-XA is used in industrial settings that require reliable and precise analog control of mechanical components in hazardous locations.

- Oil & Gas: In refineries and offshore platforms, it controls the position of critical valves to regulate flow, pressure, and temperature with high accuracy and safety.

- Power Generation: It is a core component in a turbine’s control system, where it precisely positions valves (such as fuel gas or steam valves) to regulate speed and load in areas where explosive gases may be present.

- Industrial Automation: It is a fundamental building block in automated manufacturing processes that require precise and reliable control in hazardous locations.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922