الوصف

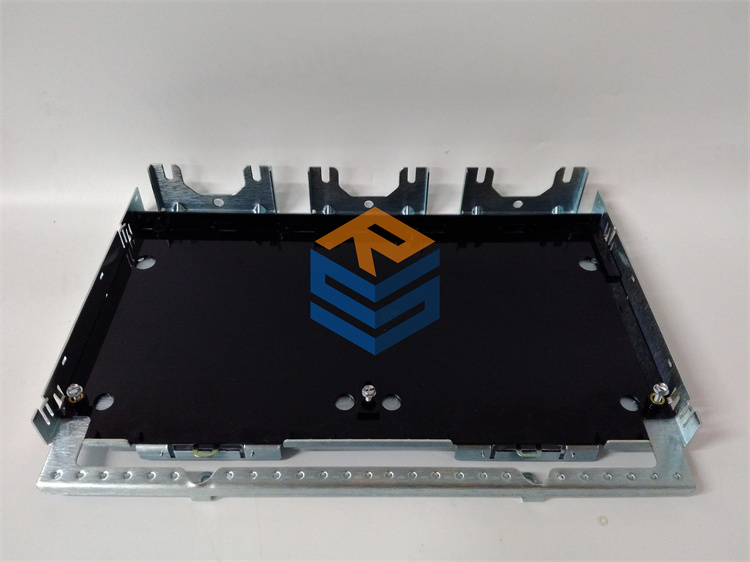

The GE IS230TNSVH3A is a triple-modular redundant (TMR) servo valve output module assembly for the GE Mark VIe control system. The part number indicates a complete, pre-configured unit with a TSVCH1A terminal board and three PSVOH1B I/O packs. This assembly is designed for highly precise and fault-tolerant control of servo valves.

Key Features

- TMR (Triple-Modular Redundant): This is the most critical feature. The TMR configuration uses three identical I/O packs to control the same servo valve. A voting algorithm compares the commands from all three packs, ensuring that the control system sends the correct signal even if one or two modules fail. This redundancy is crucial for preventing a turbine trip or other critical event due to a single component failure.

- Servo Valve Output: The module’s primary function is to send continuous, high-resolution analog signals (typically current or voltage) to precisely control the position of a servo valve. These valves are used for highly dynamic control of hydraulic actuators, which are essential for positioning turbine valves and other critical machinery.

- Assembly: The part number signifies a complete unit, consisting of both the terminal board (TSVCH1A) where the field wiring is terminated and the three electronic I/O packs (PSVOH1B) that process the signals.

- Mark VIe Integration: As part of the IS230 series, this assembly is a key component of the Mark VIe control platform, which is widely used for controlling turbines in power generation and other heavy industries.

Applications

The IS230TNSVH3A is used in mission-critical industrial settings where a loss of control of a servo valve could lead to a catastrophic event or significant downtime.

- Power Generation: It is a core component in a turbine’s control and protection system, providing a reliable input for trip logic that shuts down the unit in a controlled manner if an over-temperature condition is detected in a bearing, exhaust, or other critical component.

- Safety Systems: The TMR configuration makes it integral to safety-instrumented systems, where a failure to monitor a temperature signal could result in equipment damage or a safety risk.

- Oil and Gas: In refineries and offshore platforms, it monitors the temperature of critical equipment like pumps, compressors, and reactors to ensure they operate within safe limits.

The GE IS230TNSVH3A is a triple-modular redundant (TMR) servo valve output module assembly for the GE Mark VIe control system. The part number indicates a complete, pre-configured unit with a TSVCH1A terminal board and three PSVOH1B I/O packs. This assembly is designed for highly precise and fault-tolerant control of servo valves.

Key Features

- TMR (Triple-Modular Redundant): This is the most critical feature. The TMR configuration uses three identical I/O packs to control the same servo valve. A voting algorithm compares the commands from all three packs, ensuring that the control system sends the correct signal even if one or two modules fail. This redundancy is crucial for preventing a turbine trip or other critical event due to a single component failure.

- Servo Valve Output: The module’s primary function is to send continuous, high-resolution analog signals (typically current or voltage) to precisely control the position of a servo valve. These valves are used for highly dynamic control of hydraulic actuators, which are essential for positioning turbine valves and other critical machinery.

- Assembly: The part number signifies a complete unit, consisting of both the terminal board (TSVCH1A) where the field wiring is terminated and the three electronic I/O packs (PSVOH1B) that process the signals.

- Mark VIe Integration: As part of the IS230 series, this assembly is a key component of the Mark VIe control platform, which is widely used for controlling turbines in power generation and other heavy industries.

Applications

The IS230TNSVH3A is used in mission-critical industrial settings where a loss of control of a servo valve could lead to a catastrophic event or significant downtime.

- Power Generation: It is a core component in a turbine’s control and protection system, providing a reliable input for trip logic that shuts down the unit in a controlled manner if an over-temperature condition is detected in a bearing, exhaust, or other critical component.

- Safety Systems: The TMR configuration makes it integral to safety-instrumented systems, where a failure to monitor a temperature signal could result in equipment damage or a safety risk.

- Oil and Gas: In refineries and offshore platforms, it monitors the temperature of critical equipment like pumps, compressors, and reactors to ensure they operate within safe limits.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922