الوصف

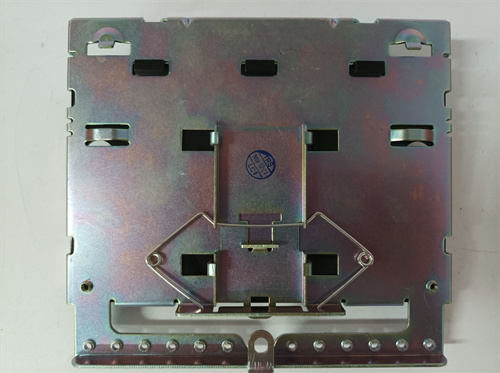

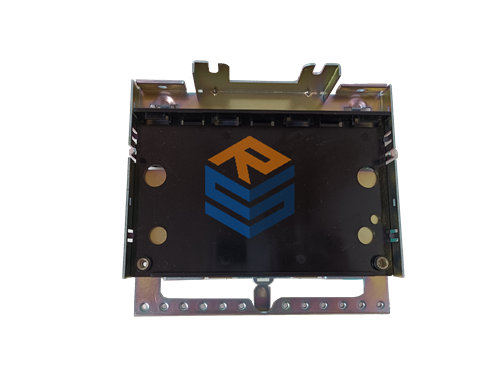

The GE IS230TRTDH1D is a simplex RTD input module assembly for the GE Mark VIe control system. This is a complete, pre-configured unit designed for non-redundant temperature monitoring using RTD (Resistance Temperature Detector) sensors.

Key Features

- Simplex Configuration: The term “simplex” means it has a single, non-redundant I/O channel. This is a cost-effective choice for applications where a single point of failure won’t lead to a catastrophic event.

- RTD Input: The module is specifically designed to handle inputs from Resistance Temperature Detectors (RTDs). RTDs are highly accurate temperature sensors that work by measuring changes in electrical resistance. The module accurately converts this resistance change into a temperature reading for the control system.

- Assembly: The part number signifies a complete, ready-to-install unit, consisting of both a terminal board and the electronic I/O pack.

- Mark VIe Integration: As part of the IS230 series, this assembly is a key component of the Mark VIe control platform, which is widely used for controlling turbines in power generation and other heavy industries.

Applications

The IS230TRTDH1D is used in industrial settings where the monitoring of temperature is essential for safe operation.

- Power Generation: It is a core component in a turbine’s control and protection system, providing a reliable input for trip logic that shuts down the unit in a controlled manner if an over-temperature condition is detected in a bearing, exhaust, or other critical component.

- Industrial Automation: The module is a fundamental building block in many manufacturing processes that rely on automated control for efficiency and product quality.

- Oil and Gas: In refineries and offshore platforms, it monitors the temperature of critical equipment like pumps, compressors, and reactors to ensure they operate within safe limits.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922