الوصف

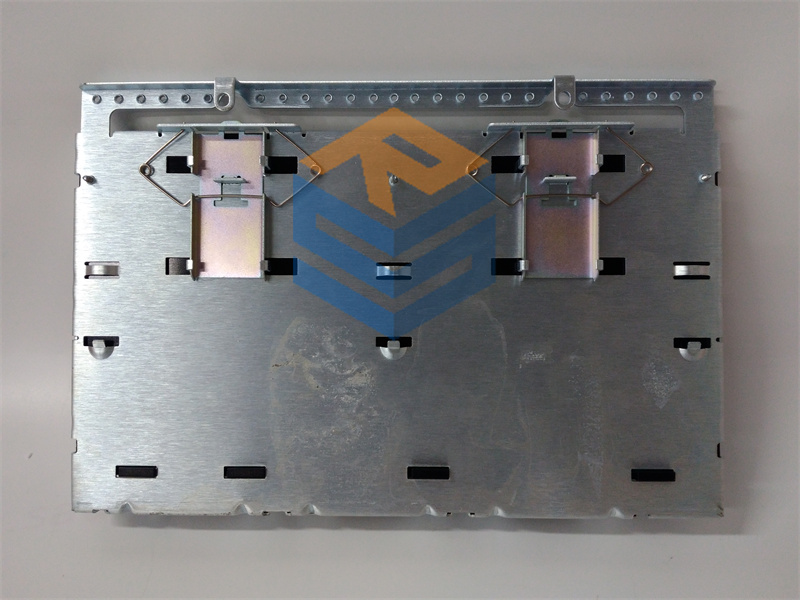

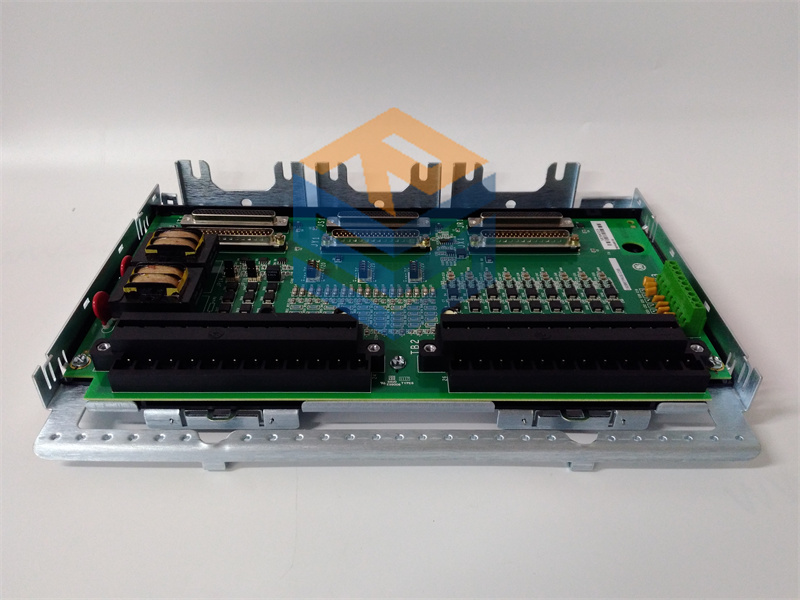

GE IS415UCCCH4A: Mark VIe CPCI CPU Board

The GE IS415UCCCH4A is a core component of the GE Mark VIe control system. As a CPCI CPU board, it acts as the central processing unit, the “brain,” of the control system. It’s responsible for executing the control logic, managing communication, and processing all the data from the various input/output (I/O) modules in the system.

This board is essential for controlling and protecting critical machinery such as gas and steam turbines, generators, and compressors in demanding industrial environments.

Key Features and Applications

The IS415UCCCH4A is a powerhouse designed for reliability and performance in industrial settings.

- CPCI (CompactPCI) Architecture: The board is built on the CPCI standard, a rugged, high-performance bus often used in industrial and telecommunications applications. This architecture provides high-speed data transfer and is mechanically designed to withstand high vibration and shock, ensuring reliable operation in harsh environments.

- Central Processing Unit (CPU): As the CPU, this board handles all the core functions of the Mark VIe system. It processes complex algorithms, runs the control software, and coordinates all the I/O operations. Without this board, the system cannot function.

- High Reliability and Redundancy: The Mark VIe system is known for its high availability. This CPU board is often part of a TMR (Triple Modular Redundancy) or redundant configuration, where multiple CPU boards work in parallel. This design allows the system to continue operating even if one or two boards fail, ensuring uninterrupted control of critical assets.

- Data Processing: The board takes in data from various field devices (sensors, transmitters, etc.), processes it, and sends commands back out to actuators and other control devices. Its high processing power allows for real-time control and data logging, which is crucial for safety and efficiency.

The IS415UCCCH4A is a critical component in the following applications:

- Power Generation: Used in control systems for large-scale gas turbines, steam turbines, and hydroelectric generators to ensure stable power output and prevent catastrophic failures.

- Oil and Gas: Employed in control systems for pipeline compressors, pumps, and other machinery to maintain safe and efficient operations.

- Chemical and Petrochemical Plants: Used to control complex processes and ensure safety interlocks on critical equipment.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922