الوصف

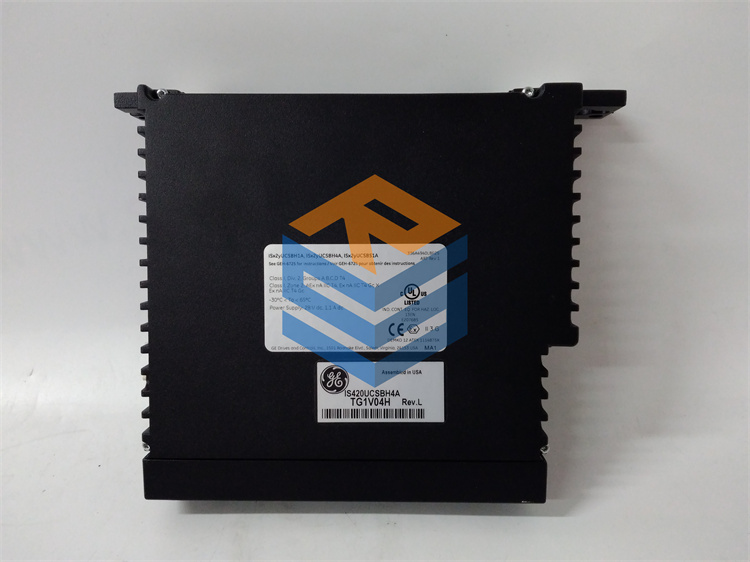

The GE IS420UCSBH4AAX is a high-performance Controller Module for the Mark VIe control system. It acts as the central processing unit, or “brain,” of the system, running the control logic and managing all communications. This particular model features a 1066 MHz processor and is certified for use in hazardous locations (HazLoc), making it suitable for the most demanding and safety-critical industrial environments.

Key Features and Applications

This module is designed for applications where high speed, reliability, and safety in potentially explosive environments are paramount.

- 1066 MHz Processor: The high clock speed indicates the module’s ability to execute control loops at very high speeds and process a large volume of data in real-time. This is essential for applications that require fast response times to maintain stability and safety, such as in high-speed machinery.

- UCSB Controller: The “UCSB” (Unit Controller System Board) is the core of the Mark VIe’s control architecture. It handles complex algorithms and real-time decision-making for controlling critical equipment like gas and steam turbines.

- Hazardous Location (HazLoc) Certification: The “AAX” at the end of the part number is a crucial safety designation. It indicates that the controller has been designed and tested to meet strict safety standards, ensuring it will not produce sparks or excessive heat that could ignite flammable gases, vapors, or dust. This is essential for safety and regulatory compliance in high-risk areas.

- System Redundancy: The Mark VIe system is known for its high availability. The IS420UCSBH4AAX is often used in redundant configurations where multiple controllers work in parallel. If one controller fails, the others take over seamlessly, ensuring no interruption in control and providing maximum system availability and safety.

Common Applications

The GE IS420UCSBH4AAX is a vital component in the following industries:

- Oil and Gas: Deployed in control systems for offshore platforms, refineries, and pipelines in areas with explosive atmospheres.

- Power Generation: Used to control and protect gas and steam turbines in areas that may have a risk of gas leaks or combustible dust.

- Chemical and Petrochemical Plants: Employed in facilities that process flammable or volatile chemicals, where safety and operational continuity are paramount.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922