الوصف

GE IS200AEAAH1C Printed Circuit Board, a specialized component within the GE Speedtronic Mark VI series.

The functional acronym AEAA stands for Alternative Energy Assembly.1 This board is a critical interface and I/O module specifically designed to handle the complex control and monitoring requirements of renewable and auxiliary systems, often found in Wind Turbine Control Systems integrated with the Mark VI platform.

Since you have not provided the product link, I will use a generic link to a GE Automation Solutions page as a placeholder. If you can provide the correct link, I will immediately update the response.

Product Description

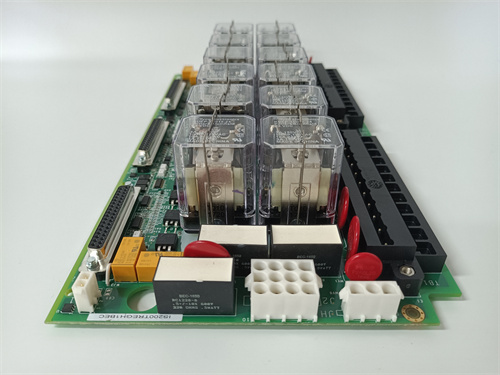

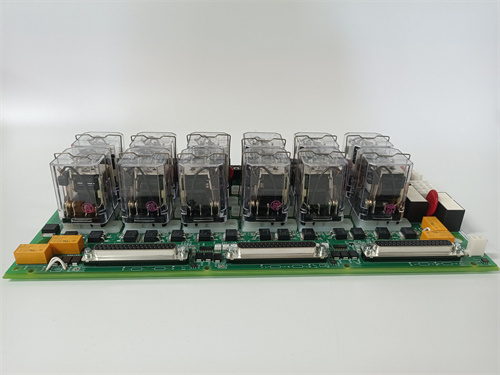

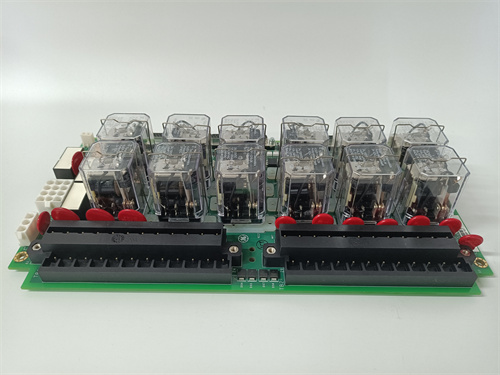

The GE IS200AEAAH1C (Placeholder Link: GE Automation Solutions Product Page) is a large, component-dense Printed Circuit Board (PCB) manufactured by General Electric. It is not a CPU, but an advanced I/O and interface module that connects various field devices—particularly those related to alternative energy or turbine auxiliary systems—to the main Mark VI control processor.

The AEAA board integrates robust circuitry for signal conditioning, power switching, and high-density field wiring termination.2 Its physical characteristics and components point to a sophisticated role in controlling mechanical and electrical systems:

- Integrated Relays: It is equipped with up to eight on-board relays (3$\text{K1}$ through 4$\text{K8}$), used for switching and controlling actuators in the field (e.g., yaw drives, brake mechanisms, or power control circuits).5

- High Component Count: The board is populated with over 40 integrated circuits, along with resistors (including wire-wound resistors), capacitors, and heat sinks, indicating significant signal processing and current/voltage handling capability.6

- Field Wiring Interface: It typically features three parallel terminal strips, each with twelve positions, offering a high volume of secure connection points for field wiring.7

- Environmental Protection: The presence of the ‘C’ suffix often denotes a board with Conformal Coating for protection against moisture, dust, and corrosive elements, which is essential for equipment exposed to harsh industrial or outdoor environments (like wind farms).8

The IS200AEAAH1C is a normal assembly (non-VME faceplate style) board, designed to be mounted inside the control cabinet.9 The H1C suffix denotes a specific hardware and firmware revision, ensuring compatibility with the Mark VI system’s overall software build.

Product Parameters

As a dedicated Alternative Energy interface board, its key technical specifications typically include:

| Parameter | Specification |

| Manufacturer/Series | General Electric, Mark VI Speedtronic Control System |

| Functional Abbreviation | AEAA (Alternative Energy Assembly) |

| Product Type | Advanced I/O and Interface PCB |

| Field Interface | Three 12-position terminal strips |

| Output Components | Up to 8 on-board Relays ($\text{K1–K8}$) |

| Component Density | High (over 40 $\text{IC}$s, resistors, heat sinks) |

| Protection | Typically Conformal Coated (‘C’ suffix) |

| Revision | H1C Hardware/Firmware Revision |

Advantages and Features

- Specialized I/O for Renewables: Provides the precise interface required for control loops common in wind turbines, managing signals for pitch, yaw, and grid equipment.

- Integrated Switching: The on-board relays simplify wiring and control logic by providing local switching capability for actuators.10

- Enhanced Durability: The Conformal Coating dramatically increases the board’s operational life in environments exposed to moisture and contamination.

- High Signal Integrity: Sophisticated circuitry ensures clean, reliable signal conditioning for both inputs and outputs, vital for accurate turbine control.11

Application Areas and Use Cases

The GE IS200AEAAH1C is primarily used in:

- Wind Turbine Control: Serving as a primary interface for systems like blade pitch, yaw control, and monitoring of generator/power conversion equipment.12

- Industrial Auxiliaries: Control of auxiliary systems that require dedicated, high-density I/O and switching capabilities.

- Mark VI Integration: Component within the GE Mark VI control cabinet to expand I/O for Balance of Plant (BOP) or specialized turbine components.13

Selection Advice and Considerations

- Revision Match is Essential: The H1C revision must be matched exactly to the unit being replaced. Minor revisions in Mark VI hardware often involve changes in firmware or component scaling that can cause incompatibility issues.

- Environmental Needs: If your control cabinet is in a harsh environment, confirming the presence of the conformal coating (often indicated by the ‘C’ or ‘H’ suffix) is a significant advantage for longevity.

- ESD Precautions: Due to its component density, treat the board with strict Electrostatic Discharge (ESD) handling precautions during any installation or removal process.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922