الوصف

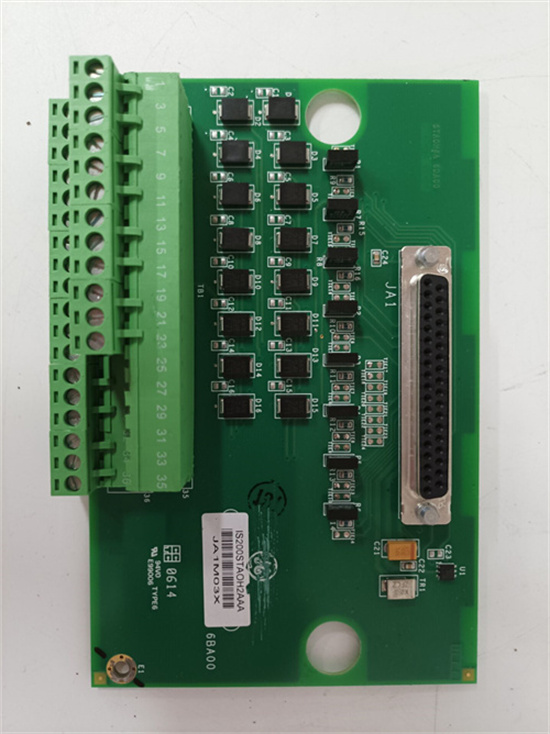

The GE IS200ISBAH1ABA is a specific revision of the PC/104 InSync ISBus Board, often referred to as an ISBus Daughter Board, used within the GE Mark VI Speedtronic Turbine Control System and the EX2100 Excitation Control System.1

This board is essential for high-speed, real-time synchronized communication between critical control modules in the system.2

⚙️ Function and Role

The primary function of the IS200ISBAH1ABA is to provide the communication interface known as the ISBus (InSync Bus).3

-

Real-Time Synchronization: The ISBus is a high-speed communication network designed to ensure that multiple controllers and I/O modules—especially those in triple-redundant (TMR) configurations—operate with a precise, synchronized time base.4 This is critical for accurate control and protection functions in a turbine system.

-

Daughter Board: The IS200ISBAH1ABA acts as a daughter board, meaning it connects directly to a larger primary board, typically the Application Control Layer Module (ACLI).5

-

Communication Channels: It provides two ISBus communication channels, often labeled INSYNC A and INSYNC B on the ACLI ports, which enable the synchronized data transfer across the network.6

-

Interface: It utilizes a PC/104 port for its physical connection to the transition or backplane board, which is a common, rugged bus standard in embedded industrial applications.7

The ABA suffix in the part number denotes the specific functional and artwork revision of the board.

🔍 Technical Features

| Feature | Detail |

| Product Type | PC/104 InSync ISBus Board (ISBus Daughter Board) |

| System | GE Mark VI Speedtronic / EX2100 Excitation System |

| Interface Ports | PC/104 port for main connection; Header port for signaling. |

| Communication | Two ISBus channels (INSYNC A and B). |

| Diagnostics | Includes status LEDs (Green for “online,” Yellow for “recording”) for each channel. |

| Construction | Features a conformal coating, a thin layer of chemical protection applied to the PCB to guard against moisture, dust, and contaminants common in industrial settings. |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922