الوصف

Product Name:

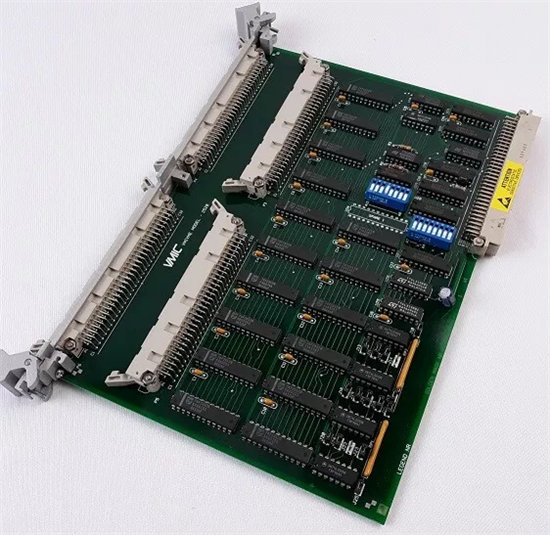

GE VMIVME-2170A DCS/PLC Module

Product Description:

The GE VMIVME-2170A is a VMEbus based Distributed Control System (DCS) or Programmable Logic Controller (PLC) module designed by GE Automation (formerly part of GE Fanuc). The VMIVME-2170A module is primarily used in industrial automation, process control, and monitoring systems. It serves as a versatile control unit that integrates with VME-based control systems for high-speed data processing, real-time control, and communication within complex automation environments.

VMEbus refers to the Versa Modular Europe architecture, which is a modular system commonly used in embedded systems. The VMIVME-2170A provides an interface for industrial control applications, combining the benefits of programmable logic with distributed control capabilities.

Key Features:

- VMEbus-Based Architecture: Allows for high-speed, real-time data exchange with other modules in a VMEbus control system.

- Flexible I/O: Supports a variety of digital and analog I/O modules, providing broad connectivity for industrial sensors, actuators, and control devices.

- Modular Design: Allows for flexible expansion and system configuration to meet specific automation needs.

- Real-Time Performance: Suitable for controlling fast industrial processes requiring rapid response times.

- Industry Protocols: Supports a range of communication protocols for data exchange between modules and with supervisory control systems.

- High Reliability: Designed for continuous, 24/7 operation in critical industrial environments.

Product Parameters & Specifications:

1. General Specifications:

- Model Number: VMIVME-2170A

- Type: DCS/PLC module

- Form Factor: VMEbus card, designed to be used in VME systems.

- Manufacturer: GE Automation, part of General Electric (GE) Power.

- Function: Provides real-time control, monitoring, and data processing for industrial automation applications.

- Compatible with: GE’s Proficy iFix, Cimplicity, or other GE control software packages.

2. Electrical Specifications:

- Operating Voltage: Typically 5V DC for logic and processing circuitry, though some models may support different input voltage ranges.

- Power Consumption: Usually 5W to 10W depending on configuration and connected modules.

- Input Voltage Range: Typically supports 5V DC or 24V DC for digital inputs and outputs.

- Output Voltage: Standard 24V DC for controlling industrial equipment (relays, solenoids, etc.).

- I/O Voltage: Digital I/O typically operates at 24V DC, with 4-20mA or 0-10V analog I/O options available.

3. I/O Specifications:

- Digital Inputs: Typically supports 8, 16, or 32 digital input channels (discrete sensors, switches, etc.).

- Digital Outputs: Usually includes 8, 16, or 32 digital output channels for controlling external devices such as actuators, relays, and valves.

- Analog Inputs: Commonly supports 4-20mA or 0-10V for analog input devices such as temperature sensors, pressure transducers, and flow meters. Typically supports up to 8 to 16 channels.

- Analog Outputs: Supports 4-20mA or 0-10V analog outputs for controlling variable devices like valves and motor speed controllers.

- Communication: Integrated Ethernet, Modbus, or Profibus communication interfaces for integration with higher-level SCADA or DCS systems.

4. Communication Protocols:

- VMEbus Interface: Primary communication bus for communication between the VMIVME-2170A module and other modules in the control system.

- Modbus: Supported for device-to-device communication in industrial applications.

- Ethernet/IP: Allows seamless connection to broader control systems and remote monitoring tools.

- Profibus: For device communication over fieldbus networks commonly used in industrial automation systems.

5. Environmental Specifications:

- Operating Temperature: Typically between 0°C and 60°C (32°F to 140°F), suitable for most industrial environments.

- Storage Temperature: Ranges from -40°C to 85°C (-40°F to 185°F) for safe storage.

- Relative Humidity: Can operate in environments with 5% to 95% non-condensing humidity.

- Vibration Resistance: Built to withstand moderate levels of vibration, meeting standard industrial requirements.

- Shock Resistance: Designed to resist shock within the typical range found in industrial settings.

6. Performance Specifications:

- Scan Time: High-speed real-time performance with scan times as low as 10ms to 50ms for fast feedback loops and critical control applications.

- Processor Speed: Features a 32-bit processor with high-speed processing capability for real-time automation.

- Memory: Typically comes with 512MB to 2GB of memory for internal data storage and buffering.

- Control Capacity: Supports the execution of complex control algorithms, including PID control, state machines, and sequencing.

7. Safety and Protection:

- Overvoltage Protection: The module includes internal overvoltage protection for added reliability in harsh industrial environments.

- Short-Circuit Protection: Built-in protections for connected devices to prevent damage from short circuits.

- Fault Detection: Continuous diagnostics and self-checking features to detect hardware or software malfunctions.

- Isolation: Provides electrical isolation for signal inputs and outputs to minimize noise interference and ground loops.

8. Application Examples:

- Power Generation: Used to automate control of turbines, generators, and auxiliary systems in power plants.

- Water Treatment: Control of pumps, valves, and chemical dosing in water or wastewater treatment plants.

- Oil & Gas: Suitable for remote monitoring and control of oil rigs, pipeline systems, and gas compression stations.

- Manufacturing: Common in industrial assembly lines, robotic arms, and factory automation applications.

- Chemical Processing: Used in controlling processes like mixing, heating, or chemical reactions where precise control is crucial.

Conclusion:

The GE VMIVME-2170A DCS/PLC Module is a reliable and high-performance control module designed for integration into VMEbus-based control systems. It offers real-time control, flexible I/O options, and supports various communication protocols like Modbus, Ethernet/IP, and Profibus for seamless integration into industrial automation environments.

This module is ideal for applications requiring fast, reliable control and monitoring, including power generation, chemical processing, water treatment, and manufacturing. Its modular and scalable design allows it to be tailored to fit specific control requirements in complex industrial systems.

For detailed installation guides, software compatibility, and application examples, please refer to the specific GE Automation product documentation or contact GE Support for additional resources.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922