الوصف

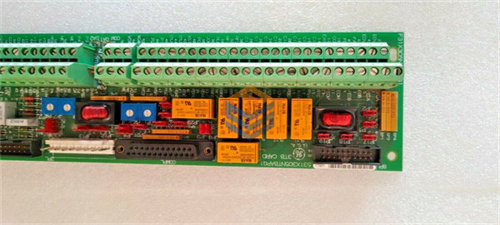

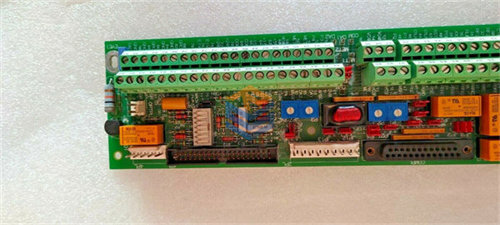

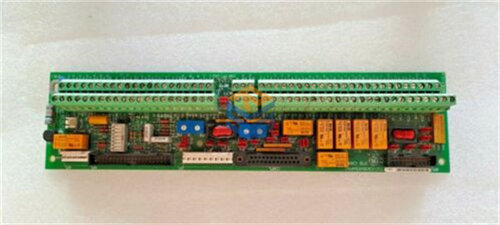

The GE+531X305NTBAPG1 is a Distributed Control System (DCS) PLC module used for industrial automation and process control applications. Below is a detailed overview of its product name, description, parameters, and specifications.

Product Name:

GE+531X305NTBAPG1 DCS PLC Module

Product Description:

The GE+531X305NTBAPG1 is a high-performance PLC module designed as part of the GE Fanuc 90-30 series of control systems. This module integrates into a Distributed Control System (DCS) or Programmable Logic Controller (PLC) setup, offering powerful and reliable process control capabilities for industries such as oil and gas, chemical processing, power generation, and manufacturing. It provides efficient real-time control, flexible communication options, and redundant features to ensure continuous operation in mission-critical environments.

This module is designed for use in complex control systems where reliability, performance, and scalability are crucial. It can be easily integrated into an existing control architecture or deployed as part of a new system setup.

Product Parameters & Specifications:

Module Type:

- PLC Module for the GE Fanuc 90-30 series and compatible DCS systems.

Control Type:

- Process Control and Discrete Control capabilities for various industrial applications.

Input/Output Configuration:

- Digital Inputs/Outputs: Supports multiple digital I/O points to control and monitor discrete devices.

- Analog Inputs/Outputs: Supports analog I/O to measure and control continuous processes, such as temperature, pressure, flow, and level.

Communication Interfaces:

- Ethernet/IP: For high-speed and reliable communication within control networks.

- Modbus TCP/IP: Industry-standard communication protocol for connecting with field devices and other automation equipment.

- Profibus DP: A communication protocol used to link PLCs to field devices such as sensors, actuators, and controllers.

- Redundant Communication Paths: Offers communication redundancy to ensure system reliability and uptime.

Power Supply:

- Operates on 24V DC.

- Includes redundant power supply options to ensure uninterrupted power in critical operations.

Redundancy:

- Hot-Swap Capability: Allows modules to be replaced or upgraded without interrupting system operations.

- Redundant System Architecture: Provides backup configurations to prevent downtime in critical processes.

Operating Temperature:

- Operating Temperature Range: Typically -20°C to +60°C (-4°F to +140°F).

- Storage Temperature Range: -40°C to +85°C (-40°F to +185°F).

Dimensions:

- Dimensions vary based on specific configuration, but generally compact for easy integration into control cabinets.

Environmental Protection:

- IP20 Rating: Intended for indoor use with protection from dust and direct contact, suitable for environments with moderate protection needs.

Safety Certifications:

- Compliant with relevant international safety and quality standards, such as ISO 9001, IEC 61508 (Functional Safety), and UL (Underwriters Laboratories).

Processing Power:

- Equipped with a high-performance processor capable of handling complex control tasks with real-time processing capabilities.

- Supports multiple processing units for parallel control and high-speed data handling.

Key Features & Benefits:

-

Real-Time Control:

The GE+531X305NTBAPG1 provides precise real-time control, ensuring timely responses to process variables and operations. This is critical in industries where system performance must be monitored and adjusted instantly. -

Redundancy and Reliability:

The module features redundant communication and power supply to maintain operational integrity even if one system component fails. This is essential for mission-critical systems that cannot afford downtime. -

Scalability:

The module can be integrated into small to large-scale systems, making it adaptable to a wide range of industrial applications and allowing future expansion as control system needs evolve. -

Flexibility:

The GE+531X305NTBAPG1 is highly versatile with its support for multiple communication protocols, including Ethernet/IP, Modbus TCP/IP, and Profibus DP, enabling seamless integration with third-party devices and equipment. -

Advanced Diagnostics:

The module includes built-in diagnostic capabilities to help quickly identify faults and improve system maintenance. This reduces unplanned downtime and enhances system reliability. -

Compact Design:

Its compact form factor and easy installation design make it a suitable choice for tight spaces and crowded control cabinets without compromising on performance.

Applications & Use Cases:

- Oil & Gas: Process control and automation for upstream and downstream operations, including refineries and offshore platforms.

- Chemical Processing: Managing chemical reactions, mixing, and temperature control processes.

- Power Generation: Used in power plants, including renewable and non-renewable generation, to monitor and control energy production processes.

- Manufacturing: Automation of manufacturing processes, assembly lines, and quality control systems.

- Water Treatment: Control and monitor the water purification and distribution processes in municipal systems.

Comparison with Other PLC Modules:

The GE+531X305NTBAPG1 stands out in terms of its redundant features, real-time processing, and scalability compared to other PLC modules like those from Siemens or Schneider Electric. It is particularly effective for applications where reliability and continuous operation are crucial, such as energy production and chemical manufacturing.

Recommendation:

The GE+531X305NTBAPG1 is recommended for use in mission-critical environments where system uptime, process control precision, and safety are of paramount importance. It is a strong choice for industries such as oil and gas, chemical processing, and power generation, where a high level of reliability and redundancy is needed.

Let me know if you need more information or comparisons with other models!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922