الوصف

The GE 531X307LTBAFG1 is a DCS/PLC module used in industrial automation systems, often within General Electric’s (GE) legacy control systems. The module is part of GE’s Mark VIe and Mark VI control systems, which are used for controlling and automating processes in power plants, industrial facilities, and other critical infrastructure.

Here are the product name, product description, product parameters, and specifications for the GE 531X307LTBAFG1 DCS/PLC Module:

Product Name:

GE 531X307LTBAFG1 DCS PLC Module

Product Description:

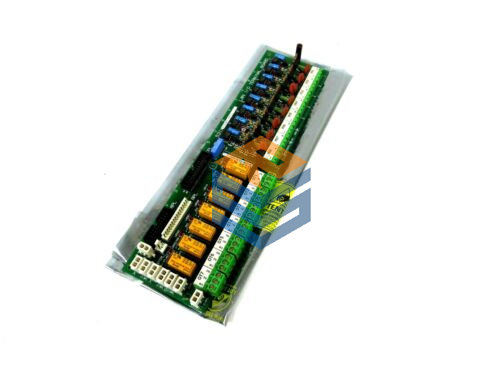

The GE 531X307LTBAFG1 module is a communication interface module designed for use within GE’s Mark VI and Mark VIe control systems. This module plays a vital role in providing communication between various field devices, controllers, and systems in industrial applications, such as power generation, oil & gas, and other manufacturing or process industries.

It serves as an interface for digital and analog signals, enabling effective integration and control of complex industrial systems. Its main function is to act as an interface for input/output (I/O) modules, sensors, actuators, and other process-related devices within the broader Distributed Control System (DCS) or Programmable Logic Controller (PLC) setup.

Product Parameters & Specifications:

General Specifications:

- Module Type: Communication Interface/Field I/O Module

- Part Number: 531X307LTBAFG1

- System Type: Part of GE Mark VI and Mark VIe control systems

- Function: Provides interface for digital and analog I/O signals between the controller and the field devices (sensors, actuators, etc.) in industrial automation processes.

- Input/Output (I/O) Types:

- Digital Inputs/Outputs (DI/DO)

- Analog Inputs/Outputs (AI/AO)

- Relay Contacts

- Modbus or other communication protocols

Key Features:

- Field Device Integration: The module supports communication with a wide variety of field devices, including smart transmitters, actuators, sensors, and other industrial equipment.

- Communication Protocols: Depending on configuration, the module can support various industrial communication protocols, including Modbus, Ethernet/IP, Profibus, and other GE proprietary protocols.

- Signal Conversion: Converts analog or discrete signals into data that the DCS or PLC controller can process, facilitating control and monitoring of process operations.

- Redundancy Support: Designed for redundant configurations to ensure high availability and system resilience, particularly in mission-critical applications.

- Real-time Diagnostics: Supports built-in diagnostics, providing real-time fault detection, predictive maintenance, and troubleshooting capabilities.

- I/O Module Communication: The module serves as a vital communication link between I/O modules and the central control system (DCS/PLC), ensuring accurate and timely data transmission.

Environmental Parameters:

- Operating Temperature: Typically operates in an environment of 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -40°C to 85°C (-40°F to 185°F).

- Humidity Range: The module is designed to operate within 5% to 95% relative humidity, non-condensing.

- Vibration and Shock Resistance: Built to withstand the typical vibrations and shocks encountered in industrial environments.

Power Supply and Electrical Characteristics:

- Nominal Voltage: Typically operates at 24V DC (common in industrial control systems).

- Current Consumption: This can vary based on system configuration and load but typically falls in the range of 500mA to 1A for normal operations.

- Power Consumption: Depends on the configuration but typically less than 20 watts for the base module.

I/O Capacity:

- Digital I/O: Handles discrete input and output signals for control and monitoring of on/off devices, such as switches, relays, and valves.

- Analog I/O: Supports analog inputs and outputs for more precise control over variables like temperature, pressure, and flow.

- Relay Contacts: The module may include relay contact outputs for controlling other devices such as alarms or emergency shutdown systems.

Fault Tolerance and Redundancy:

- Hot Standby Redundancy: Supports redundant communication links and power supplies to ensure minimal downtime and high system availability.

- Fault Detection and Diagnostics: The module includes self-diagnostic features, allowing the system to detect and report faults such as communication errors, power issues, or I/O failures.

- System Redundancy: The module can be configured for use in critical applications where redundancy is essential to maintain continuous operations.

Mounting and Physical Specifications:

- Mounting Type: The module is typically installed in rack-mounted control systems (19-inch racks) or specific control panels designed for the GE Mark VIe or Mark VI systems.

- Module Dimensions: The physical dimensions will depend on the specific rack or system used, but the module itself is typically around 6-8 inches in height and 10-12 inches in depth.

- Weight: Approximately 2-3 kg (depends on specific configuration).

User Interface and Configuration:

- Configuration and Setup: Configuration is handled through GE’s proprietary software tools, such as ControlST or System Software interfaces, enabling users to configure I/O settings, diagnostics, and communication protocols.

- Communication Ports: The module includes ports for network communication (Ethernet, serial, etc.), ensuring seamless integration into the larger DCS or PLC network.

- Diagnostics Interface: Provides a diagnostics interface for monitoring the health and status of connected devices and the system as a whole.

Software and Integration:

- Software Compatibility: The module integrates with GE’s Mark VI and Mark VIe control systems and is compatible with the ControlST software suite for configuring and managing the system.

- Data Logging and Reporting: The system can log performance data, generate diagnostic reports, and support predictive maintenance strategies through its communication protocols.

Summary:

The GE 531X307LTBAFG1 module is a key component within GE’s Mark VI/Mark VIe DCS/PLC systems, facilitating reliable communication and control between field devices and the central processing system. With its support for analog and digital I/O, redundancy features, and real-time diagnostics, it is well-suited for mission-critical applications in industries such as power generation, chemical processing, and manufacturing.

This module helps ensure high system availability, fault tolerance, and easy integration with a wide variety of field devices, making it an essential part of complex industrial control systems.

Let me know if you need more detailed information on configuring the module or specific applications!

MA-0329-001

MA-0186-100 PLC DCS

MA-0185-100 PLC DCS

LXM15MD28N4 PLC DCS

BMXFTB2010 PLC DCS

ATV61HD37N4 PLC DCS

AS-S908-110 PLC DCS

AS-P890-000 PLC DCS

AS-J890-101 PLC DCS

AS-B805-016 PLC DCS

AM-SA85-000 PLC DCS

140CPUCPU 140CPU67160 140-CPU-651-50 PLC DCS

140NOE77101 PLC DCS

140CRA93200 PLC DCS

140CRP93100 PLC DCS

140DDI84100 PLC DCS

140DDO84300 PLC DCS

140DAI74000 PLC DCS

140DAO84000 PLC DCS

140ACI04000 PLC DCS

140ACO02000 PLC DCS

140AVI03000 PLC DCS

140XBP Backplane 140XBP01000 PLC DCS

140XTS Terminal Strip 140XTS00200

P0961BS-OC FOXBORO

P0931RQ FOXBORO

P0931RM

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922