الوصف

The GE+D20 MIC 10BASE-T DCS/PLC Module appears to be a specialized module designed for distributed control systems (DCS) or programmable logic controllers (PLC), providing network connectivity, possibly focused on Ethernet communication standards such as 10BASE-T (a standard for 10 Mbps Ethernet over twisted-pair cabling).

While specific details on this exact module (GE+D20 MIC 10BASE-T) aren’t available from my training data, I can give you an outline of what a typical GE (General Electric) D20 MIC (Modular Interface Controller) with 10BASE-T Ethernet support might entail, based on general trends in similar modules used for DCS/PLC applications.

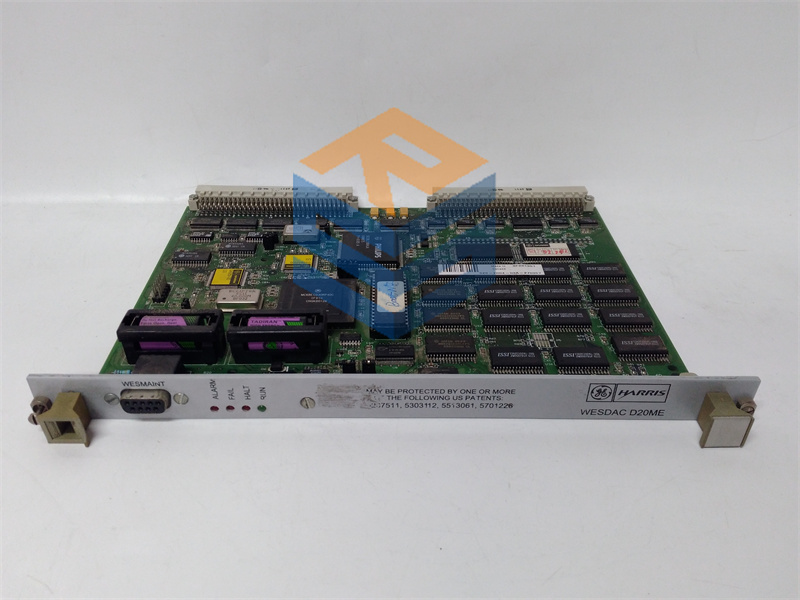

Product Name:

- GE+D20 MIC 10BASE-T DCS/PLC Module

Product Description:

The GE+D20 MIC (Modular Interface Controller) with 10BASE-T Ethernet capability is a network interface module designed for integration with distributed control systems (DCS) or programmable logic controllers (PLC). The module enables communication and data exchange between field devices and control systems, utilizing Ethernet (10BASE-T) as the physical medium.

This module facilitates the connection of PLC/DCS systems to a broader network infrastructure, supporting Ethernet-based communication for high-speed data transfer between systems and devices. The 10BASE-T standard enables communication over twisted-pair cables, making it suitable for many industrial networking applications.

Key Functions:

- Ethernet Communication: The module supports 10BASE-T Ethernet networking for high-speed communication with other networked devices.

- Interfacing with Field Devices: Facilitates the connection of field sensors, actuators, and controllers to the central PLC/DCS system.

- Data Exchange: Ensures efficient data transfer between control systems and connected devices.

- Modular Design: The MIC (Modular Interface Controller) architecture likely offers modularity, allowing for the expansion or customization of system components.

Product Parameters:

-

Communication Type:

- Ethernet (10BASE-T): Uses twisted-pair cables for 10 Mbps data transmission, suitable for industrial networking and control systems.

-

Functionality:

- Data Exchange: Supports high-speed communication for seamless integration into a DCS or PLC system.

- Network Interface: Acts as a network interface for the control system, enabling seamless interaction with Ethernet-based devices or other networked PLC/DCS systems.

-

Mounting:

- Typically, modules like the GE+D20 MIC are designed for DIN rail mounting in industrial control panels, ensuring easy integration and maintenance.

-

Protocol Support:

- Depending on the application, this module might support Ethernet/IP, Modbus TCP, or proprietary GE communication protocols.

Specifications:

-

Power Supply:

- Likely operates from 24V DC or 48V DC industrial power supply, as is common for control system modules.

- Power consumption would typically depend on the specific configuration and number of connected devices.

-

Ethernet:

- 10BASE-T: This module uses standard 10 Mbps Ethernet for communication over twisted-pair cables (Category 5 or higher).

- Full-duplex Communication: Likely supports full-duplex Ethernet communication, which allows simultaneous sending and receiving of data.

-

I/O Configuration:

- Digital/Analog I/O: Depending on the exact configuration, it might provide digital or analog inputs/outputs to interface with external field devices such as sensors, actuators, and controllers.

- For PLC/DCS systems, the number of I/O points would typically depend on the application requirements.

-

Environmental Conditions:

- Operating temperature: Typically, such modules operate in the range of 0°C to 60°C, though this can vary based on specific industrial certifications.

- Humidity: Usually rated for industrial environments with relative humidity up to 95% (non-condensing).

- Shock/Vibration resistance: Designed for rugged industrial environments.

-

Mounting:

- DIN Rail Mounting: This is a common method of installation for industrial control system modules, ensuring easy integration into control cabinets.

-

Network Integration:

- Likely supports various industrial Ethernet protocols (such as Ethernet/IP, Modbus TCP, or proprietary GE protocols) for communication between PLC/DCS systems and field devices.

-

Redundancy and Reliability:

- May offer features like redundant power supplies or dual network interfaces to ensure system reliability and minimize downtime in critical control applications.

-

Safety and Compliance:

- It is expected that the module complies with international safety standards (e.g., UL, CE, IEC standards) for use in industrial environments.

- May feature protections such as overvoltage, overcurrent, and short circuit protection.

-

Certifications:

- The module may come with certifications for use in industrial environments, such as ATEX for hazardous areas, depending on its design.

Applications:

- Oil & Gas: Used in upstream and downstream applications to interface with various devices like sensors, actuators, and controllers in an Ethernet-based network.

- Chemicals & Petrochemical: Provides network communication for control systems used in chemical processing plants.

- Manufacturing Automation: Integrates machines and PLCs in manufacturing plants, supporting factory automation processes.

- Utilities: For remote monitoring and control in utility applications, such as water treatment and power generation.

- Process Control: Used in continuous process control environments like food & beverage or pharmaceuticals.

Conclusion:

The GE+D20 MIC 10BASE-T DCS/PLC Module is a network interface module that enables efficient communication over Ethernet in industrial control systems. Designed for use in DCS/PLC systems, it supports 10BASE-T Ethernet communication to allow seamless data exchange between control systems and field devices. With its rugged design and compliance with industrial standards, this module is ideal for automation, process control, and network integration in industries such as oil & gas, chemical, and manufacturing.

If you have any additional questions or need specific details about the configuration, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922