الوصف

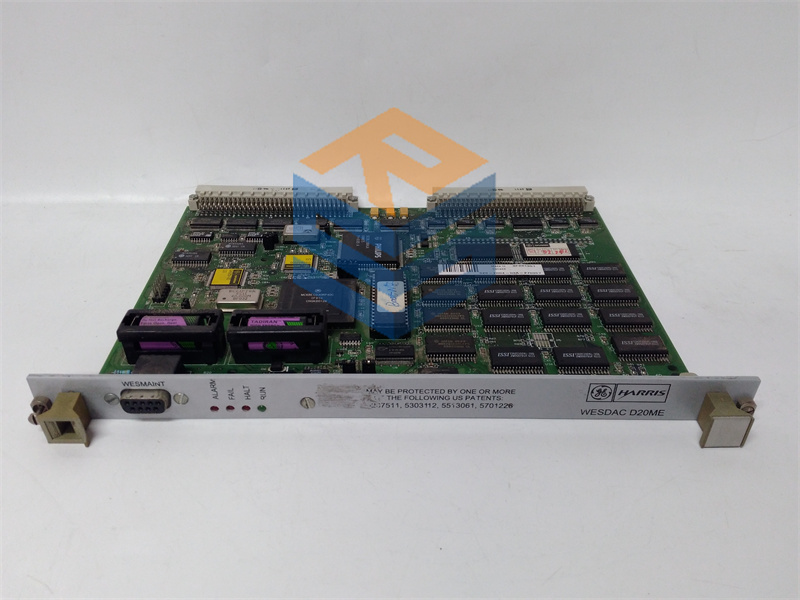

GE D20EME10BASE-T 820-0474 DCS PLC Module

1. Product Name:

GE D20EME10BASE-T 820-0474 DCS PLC Module

2. Product Description:

The GE D20EME10BASE-T 820-0474 is a highly specialized Distributed Control System (DCS) PLC module from General Electric designed to support robust process control and automation in industrial environments. This module is an integral part of GE’s D20 DCS system and is optimized for high-performance operations, including real-time monitoring, data acquisition, and control in critical industrial applications.

The D20EME10BASE-T 820-0474 module offers seamless integration with Ethernet networks, enabling efficient communication between control systems and field devices. With its high-speed processing capabilities and reliable operation, this module is used extensively in industries such as oil and gas, power generation, chemical processing, and water treatment where precision and fault tolerance are essential.

Designed with flexibility in mind, this module supports remote diagnostics and fault detection, enhancing system reliability. Additionally, its modular architecture allows for easy customization and expansion of control systems, catering to a wide range of industrial applications.

3. Product Parameters and Specifications:

Model Number:

- GE D20EME10BASE-T 820-0474

Product Type:

- DCS PLC Communication and Control Module

Manufacturer:

- General Electric (GE)

Control System Compatibility:

- Part of the GE D20 DCS System for large-scale industrial process control applications.

Physical and Mechanical Characteristics:

- Form Factor: Rack-mounted module for ease of installation in industrial control systems.

- Dimensions: Approx. 6.75 x 12.75 x 2.5 inches (may vary based on configuration).

- Weight: Typically around 2 to 3 kg, depending on configuration and installed components.

- Mounting: Designed for mounting in standard DCS control racks.

- Cooling: Utilizes passive cooling to maintain system temperature in industrial environments.

- Power Supply: Operates on a 24V DC power supply to ensure stable operation.

Operating Conditions:

- Operating Temperature: 0°C to 60°C (32°F to 140°F), suitable for most industrial environments.

- Storage Temperature: -20°C to 70°C.

- Relative Humidity: 5% to 95% (non-condensing).

- Vibration Resistance: Can withstand typical industrial vibration levels.

- Shock Resistance: Built to handle mechanical shocks during installation and operational use.

Key Features:

- Ethernet Communication: Supports 10BASE-T Ethernet protocol, allowing high-speed data transmission and communication with other devices in the DCS network.

- Modular I/O Support: The module is designed to support flexible and modular input/output configurations, accommodating a variety of industrial processes.

- Real-Time Processing: The high-speed processor enables real-time control and monitoring, crucial for time-sensitive industrial operations.

- Redundant Power: Dual power inputs for ensuring continuous operation in case of a power failure.

- Remote Diagnostics: Built-in diagnostics for monitoring system health, detecting faults, and reducing downtime.

- High Availability: Designed for critical applications that require high system availability and fault tolerance.

- Easy Integration: Supports integration with various GE DCS and PLC systems, providing flexibility for control system upgrades and expansions.

Communication and Protocols:

- Ethernet 10BASE-T: This module supports 10BASE-T Ethernet communication, providing a reliable and high-speed network connection for DCS systems.

- Modbus TCP: Supports Modbus TCP/IP for communication with field devices and other third-party systems.

- Profibus: Integration with Profibus for industrial communication with various devices and field equipment.

- HART Protocol: Communication with smart field instruments using the HART protocol for enhanced device monitoring and control.

- Redundant Network Connections: Provides dual Ethernet ports for redundancy, enhancing network reliability and uptime.

I/O Capabilities:

- Digital I/O: Supports a wide range of digital inputs and outputs, including contact closures and status signals.

- Analog I/O: Handles analog input/output signals from devices like temperature sensors, flow meters, and level transmitters.

- Modular I/O: Users can select from a variety of I/O modules tailored to meet specific process control needs.

- Flexible I/O Expansion: Allows for I/O expansion via remote I/O units to extend control system capabilities.

4. Safety and Compliance:

- Safety Standards: The module is built to meet industry safety standards and is suitable for integration into safety-critical systems where reliability is paramount.

- Environmental Compliance: Compliant with RoHS and WEEE directives to minimize environmental impact.

- Certifications: The module is UL, CE, and CSA certified, ensuring safety and quality compliance for industrial applications.

5. Applications:

The GE D20EME10BASE-T 820-0474 DCS PLC Module is ideal for use in a wide range of industries, including:

-

Oil and Gas:

- Control of offshore and onshore platforms, pipeline monitoring, and refinery automation.

- Safety monitoring and emergency shutdown systems for hazardous operations.

-

Power Generation:

- Control of power plants, substation automation, and grid distribution.

- Process monitoring and system diagnostics for continuous operation.

-

Chemical Processing:

- Process control in chemical reactors, distillation units, and batch processing systems.

- Real-time monitoring and regulatory compliance for chemical manufacturing.

-

Water Treatment:

- Pump station control, water quality monitoring, and wastewater treatment.

- Remote diagnostics and system optimization for water distribution systems.

-

Manufacturing and Automation:

- Industrial automation for assembly lines, material handling, and robotics control.

- Data collection and process optimization for efficient manufacturing operations.

6. Conclusion:

The GE D20EME10BASE-T 820-0474 DCS PLC Module is a reliable, high-performance component in GE’s D20 Distributed Control System. With its advanced Ethernet-based communication, modular I/O configuration, and real-time processing capabilities, this module provides a robust solution for industrial automation across multiple sectors. Its remote diagnostics and redundant power supply features enhance its reliability, making it an essential tool for mission-critical applications that demand high system availability and fault tolerance. Whether for energy, chemical, water, or manufacturing industries, this module helps optimize process control and ensure smooth, continuous operation.

1336F-B025-AE-EN PLC DCS

1336F-B025-AN-EN PLC DCS

1336F-B025-AN-EN-HAS1-LA4-L6 PLC DCS

1336F-B025-AN-EN-L6 PLC DCS

1336F-B030-AA-EN PLC DCS

1336F-B040 PLC DCS

1336F-B040-AA-EN PLC DCS

1336F-B040-AN-EN PLC DCS

1336F-B040-AN-EN-GM2-L6 PLC DCS

1336F-B040-AN-EN4 PLC DCS

1336F-B050-AA PLC DCS

1336F-B050-AA-EN PLC DCS

1336F-B050-AA-EN-HAS2-L6 PLC DCS

1336F-B050-AA-EN-HAS2-LA4-L6 PLC DCS

1336F-B050-AA-EN-HCS2-L6 PLC DCS

1336F-B050-AA-EN4-GM1-HA2-L6 PLC DCS

1336F-B050-AN-EN4 PLC DCS

1336F-B050-AN-EN4-GM1-HA2-L6 PLC DCS

1336F-B060 PLC DCS

1336F-B060-AA-EN-GM1 PLC DCS

1336F-B060-AA-EN-L6-HAS2 PLC DCS

1336F-B060-AN-EN-L6 PLC DCS

1336F-B075-AA-EN-HAS2-L6 PLC DCS

1336F-B100-AA-EN-GM1 PLC DCS

1336F-B100-AA-EN-HCS2-LA4-L6 PLC DCS

1336F-B100-AA-EN-HCSP-L6 PLC DCS

1336F-B100-AN-EN-HCS2-L6 PLC DCS

1336F-B100-AN-EN-L6 PLC DCS

1336F-B125-AA-EN-HCS2-L6 PLC DCS

1336F-B125-AN-EN PLC DCS

1336F-B125-AN-EN-HAS2-L4 PLC DCS

1336F-B125-AN-EN-L6 PLC DCS

1336F-B150-AN-EN-GM5-L6 PLC DCS

1336F-B200-AN-EN PLC DCS

1336F-B200-AN-EN-HAS1 PLC DCS

1336F-B250 PLC DCS

1336F-B250-AN-EN-L6 PLC DCS

1336F-B40C-AA-EN PLC DCS

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922