الوصف

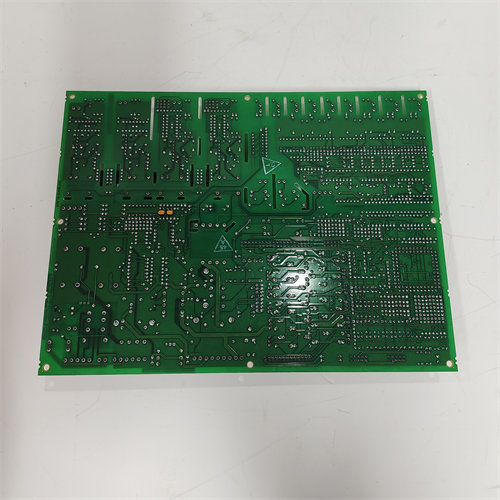

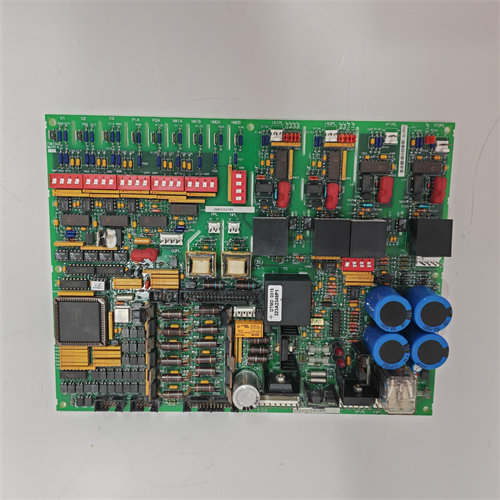

GE DS200DCFBG2BNC / DS200DCFBG1BNC DCS PLC Module

Product Name:

GE DS200DCFBG2BNC / DS200DCFBG1BNC DCS PLC Module

Product Description:

The GE DS200DCFBG2BNC and DS200DCFBG1BNC are Distributed Control System (DCS) PLC Modules designed and manufactured by General Electric (GE) for use in industrial automation and process control. These modules are part of the GE Mark VIe or Mark V control systems, typically employed in industries such as power generation, oil & gas, chemical processing, and water treatment.

These modules are critical components for controlling and monitoring industrial processes in real-time. They provide high-speed data acquisition, control, and communication between the central control system and field devices such as sensors, actuators, and process control equipment. The DS200DCFBG2BNC and DS200DCFBG1BNC modules are built to handle robust, high-performance control tasks with a focus on reliability and uptime.

These PLC modules support a variety of I/O configurations, diagnostic functions, and communication protocols, which help ensure seamless operation and integration into existing industrial control systems. They are engineered to meet the needs of process industries with stringent uptime and safety requirements.

Product Parameters:

-

Model Numbers:

- DS200DCFBG2BNC (Version 2)

- DS200DCFBG1BNC (Version 1)

-

Type:

DCS PLC (Distributed Control System Programmable Logic Controller) Module- Part of GE Mark VIe / Mark V Control Systems

-

Manufacturer:

General Electric (GE) -

System Compatibility:

Compatible with GE Mark VIe and Mark V systems for power generation and industrial control systems. -

Power Supply:

- Nominal Voltage: 24 V DC (Typically)

- Current Consumption: Varies by configuration and application.

-

Operating Temperature:

- Range: -40°C to 70°C (Standard range)

-

Weight:

- Typically around 1.5 – 2 kg (depending on the specific model)

-

Environmental Conditions:

- Humidity: Up to 95% (non-condensing)

- Vibration Resistance: Designed to meet industrial standards for high-performance reliability.

Specifications:

-

Input/Output (I/O):

- Digital Inputs (DI): Typically 16 channels

- Digital Outputs (DO): Typically 16 channels

- Analog Inputs (AI): 4-8 channels for real-time measurements

- Analog Outputs (AO): Configurable 4-8 channels for control of actuators

-

Processor:

- Real-Time Processing: The module is designed for high-speed, real-time data processing for industrial automation systems.

- Control Algorithms: Supports various industrial control algorithms including PID, cascade control, feedforward, and advanced logic control.

-

Memory:

- Typically includes sufficient memory for control logic, I/O mapping, and system diagnostics.

-

Communication Protocols:

- Ethernet for high-speed communication and integration with centralized DCS control.

- Fieldbus Support: Supports industrial protocols like Profibus, Modbus, and HART for easy communication with field devices.

- Redundant Communication: Available on select configurations for enhanced reliability and fail-safe operation.

-

System Integration:

- GE Mark VIe and Mark V Integration: Easily integrates into the GE Mark VIe and Mark V control systems, used widely in industries like power generation and oil & gas.

- Redundant Systems: Built for high availability, the modules support redundancy to reduce the risk of system downtime in critical environments.

-

Diagnostic Features:

- Self-Diagnostics: Includes onboard diagnostics and status indicators for system health monitoring and fault detection.

- Event Logging: Logs critical system events, alarms, and faults for troubleshooting and performance monitoring.

-

Safety and Reliability:

- Designed to meet SIL 2 / SIL 3 safety standards, making it suitable for safety-critical applications.

- Fail-Safe Operation: The module provides redundant pathways for data and power to ensure continuous operation even during faults.

-

Expandability:

- The system allows for easy expansion by adding additional modules, increasing its scalability to meet growing industrial needs.

-

Mounting and Form Factor:

- Typically designed as a rack-mounted module with connectors for field I/O and communication interfaces.

- Front Panel Indicators: Includes LED indicators for operational status, fault detection, and diagnostics.

Key Features:

-

High-Performance Control:

The module supports real-time, high-speed control of industrial processes, ensuring quick response times to process changes. -

Advanced Diagnostics:

Integrated diagnostics and fault detection help improve system reliability and reduce maintenance downtime. -

Flexible I/O Configurations:

The DS200DCFBG2BNC and DS200DCFBG1BNC modules support multiple digital and analog I/O channels, offering flexibility for different control and monitoring tasks. -

Integrated Safety Systems:

The module can be integrated with GE’s Safety Instrumented Systems (SIS) for applications requiring SIL 2/SIL 3 compliance. -

Communication and Networking:

Ethernet, Modbus, Profibus, and HART protocols enable easy integration with other control systems and field devices. -

Redundancy:

Redundant configurations ensure reliable operation, even in cases of communication or power failures, making it ideal for critical systems where uptime is crucial. -

Compatibility:

Fully compatible with the GE Mark VIe and Mark V control systems, making it suitable for power generation plants, refineries, chemical plants, and other industrial operations. -

Scalability:

The module can be expanded and customized to suit specific control needs, providing scalability for future upgrades.

Applications:

The GE DS200DCFBG2BNC and DS200DCFBG1BNC modules are commonly used in the following industries:

- Power Generation: For real-time control and monitoring of power plants, including turbines, generators, and other critical systems.

- Oil and Gas: Used in refining, pipeline control, and offshore platform operations, where uptime and safety are of utmost importance.

- Chemical and Petrochemical: For process control in the chemical manufacturing and refining industries.

- Water Treatment: Monitoring and control of water treatment plants and systems.

- Manufacturing and Industrial Automation: Widely used in factory automation and process control applications for various industrial operations.

Conclusion:

The GE DS200DCFBG2BNC / DS200DCFBG1BNC DCS PLC modules provide essential functionality for high-performance industrial control, offering advanced diagnostics, real-time processing, and flexible I/O configuration. With their compatibility with GE Mark VIe and Mark V systems, these modules are ideal for industries requiring robust, scalable, and fail-safe process control. They support redundant systems for enhanced reliability and integration with a wide range of industrial communication protocols, making them suitable for power generation, oil & gas, chemical processing, and more.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922