الوصف

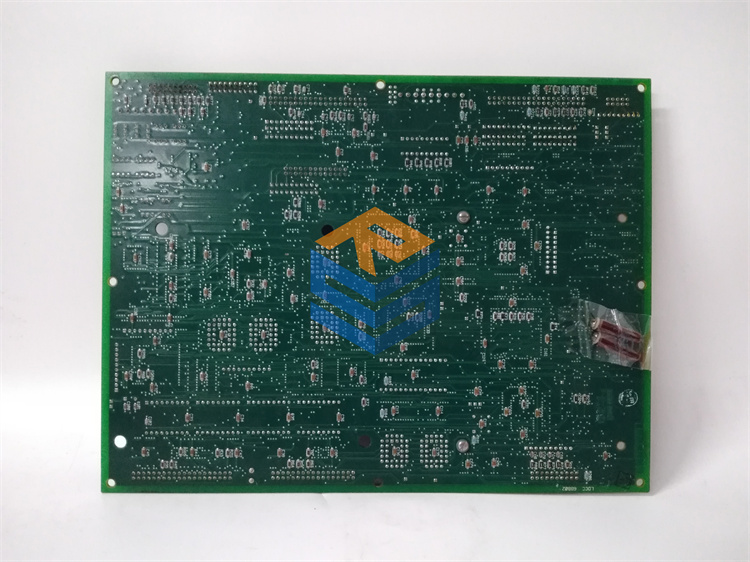

GE+DS200LDCCH1AGA PLC Module

Product Name:

GE DS200LDCCH1AGA – PLC Module

Product Description:

The GE DS200LDCCH1AGA is part of General Electric’s series of programmable logic controller (PLC) modules, designed for use in industrial automation applications. This specific module belongs to the Mark VIe control system, primarily used in power generation and industrial process control environments. It is engineered for applications that demand high performance, reliability, and flexibility in terms of both I/O processing and communication capabilities.

The DS200LDCCH1AGA is designed to control and manage a wide variety of industrial processes, making it ideal for industries like energy production, oil and gas, chemical processing, and heavy machinery. It is a distributed controller and part of a highly integrated control system, which can be expanded to support additional control modules for complex systems.

This module features integrated communication ports, I/O configurations, and support for various protocols that enable networking with other modules in the Mark VIe system. Additionally, it includes advanced diagnostic and fail-safe features to ensure stable operation in mission-critical environments.

Key Features:

- Advanced Control:

- The DS200LDCCH1AGA provides flexible, real-time control of industrial processes, making it suitable for complex systems such as power generation units or large-scale automation systems.

- Integrated I/O:

- The module supports both digital and analog I/O, allowing for control of various devices like sensors, actuators, and motors.

- Communication Protocols:

- The DS200LDCCH1AGA supports multiple communication protocols such as Modbus RTU, Ethernet/IP, and Profibus, which allow integration with other systems in the network.

- Modular Design:

- It can be easily expanded by integrating with additional GE Mark VIe modules, providing scalable solutions for large or evolving industrial systems.

- Real-time Monitoring and Diagnostics:

- Built-in real-time monitoring and diagnostic capabilities ensure that any system irregularities or faults are immediately detected and addressed.

- Safety Features:

- Equipped with redundancy and fail-safe mechanisms, ensuring operational continuity even in the case of component failures.

Product Parameters & Specifications:

General Information:

- Model: GE DS200LDCCH1AGA

- Category: PLC (Programmable Logic Controller) Module

- Series: Mark VIe Distributed Control System

- Brand: General Electric (GE)

- Part Number: DS200LDCCH1AGA

Power Supply:

-

Nominal Voltage: 24V DC

- Operating Voltage: Typically within a range of 20V to 30V DC.

- Power Consumption: 12W (approximately, depending on load).

-

Input Voltage Range:

- 24V DC ± 10% (for reliable operation).

-

Current Consumption:

- The module typically consumes less than 1A at 24V DC, but can vary based on the configuration.

Operating Conditions:

-

Operating Temperature Range:

- 0°C to 60°C (32°F to 140°F).

-

Storage Temperature Range:

- -40°C to +85°C (-40°F to +185°F).

-

Relative Humidity:

- 5% to 95%, non-condensing.

-

Vibration Resistance:

- The module is designed to meet industrial-grade vibration standards for reliability in tough environments.

I/O Specifications:

-

Digital Inputs/Outputs:

- Supports digital I/O for discrete control of machinery, motors, sensors, and alarms.

- Relay Outputs, Transistor Outputs, and Inputs.

-

Analog Inputs/Outputs:

- Provides analog I/O (e.g., 4-20mA, 0-10V) for continuous monitoring of physical processes, like temperature, pressure, and flow.

-

Communication Ports:

- Supports a variety of communication protocols, including:

- Modbus RTU (for serial communication).

- Ethernet/IP (for networking and industrial communication).

- Profibus (for field device integration).

- Supports a variety of communication protocols, including:

Environmental Ratings:

-

Ingress Protection:

- Typically IP20, which means the module is protected from solid objects greater than 12mm, but it is not water or dust-tight, and it should be installed in a protected cabinet.

-

Vibration & Shock Resistance:

- Designed to withstand industrial shock and vibration, compliant with industrial standards for equipment used in heavy-duty operations.

-

EMI and RFI Immunity:

- Built with electromagnetic interference (EMI) and radio-frequency interference (RFI) immunity to ensure reliable operation in industrial settings.

Performance & Features:

-

Processing Speed:

- High-speed control processing for real-time data handling in critical applications.

-

Redundancy and Fault Tolerance:

- Includes redundancy features for power and communications, ensuring system uptime even in the case of component failure.

-

Diagnostics & Monitoring:

- Provides self-diagnostics, fault detection, and event logging capabilities to improve system reliability and minimize downtime.

-

Network Integration:

- Ethernet/IP support enables seamless integration with PLC networks, SCADA systems, and other industrial control networks.

Applications:

-

Power Generation:

- Used for real-time control and monitoring of systems in power plants, including turbines, generators, and transformers.

-

Oil & Gas:

- Provides reliable control for pumps, compressors, and valves in oil rigs, refineries, and pipelines.

-

Chemical Processing:

- In chemical plants, it controls various safety systems, monitoring equipment, and automated processes.

-

Manufacturing Automation:

- Controls production lines, machine tools, conveyors, and other automated machinery in manufacturing facilities.

-

Water Treatment:

- Controls water flow, chemical dosing, and filtration processes in municipal and industrial water treatment plants.

Certifications and Compliance:

- CE Certified: Meets European Union standards for health, safety, and environmental protection.

- UL Listed: Complies with UL safety standards.

- RoHS Compliant: Adheres to RoHS regulations, ensuring it is free from hazardous substances.

Summary of Key Features:

- High-performance PLC module for industrial automation and control systems.

- Real-time control and monitoring of critical industrial processes.

- Wide range of I/O options, including digital, analog, and communication ports.

- Supports communication protocols like Modbus RTU, Ethernet/IP, and Profibus for network integration.

- Redundant and fault-tolerant design for high reliability in mission-critical applications.

- Diagnostic and monitoring features for easy troubleshooting and system management.

- CE, UL, and RoHS certified for compliance with industry standards.

Let me know if you’d like more details or have any specific questions about the GE DS200LDCCH1AGA module!

3BSE018157R1 PLC

ABB PM860K01 PLC

3BSE018100R1 ABB PLC

PM856K01 ABB PLC

3BSE018104R1 ABB PLC

HIEE300936R0101 PLC

ABB HIEE300936R0101 I/O

ABB HIEE300900R1 PLC

HIEE450848R1 ABB PLC

HIEE451220R1 PLC

HIEE300900R0001 ABB PLC

HIEE405179R0001 ABB PLC

ABB HIEE400109R1 I/O

HIEE220620R1 ABB PLC

ABB HIEE305106R0001 PLC

HIEE305069R1 ABB PLC

HIEE450880R1 ABB PLC

ABB HIEE400121R1 PLC

HIEE400643R1 ABB PLC

HIEE450824R1 ABB PLC

ABB HIEE400787R1 PLCPLC

ABB HIEE410103P1 PLC

HIEE305111R0001 ABB PLC

HIEE450932R1 ABB PLC

ABB HIEE401481R0001 PLC

HIEE300698R0001 ABB I/O

ABB HIEE205010R001 PLC

HIEE300888R0002 ABB PLC

ICSK20F1 ABB I/O

ABB 815-BOV169

1786-RPA ABB PLC

ABB 1786-RPFM PLC

1747-L542 ABB PLC

1747-L543 ABB DCS

ABB DAI03 PLC

ABB DAO01 PLC

ABB DAI04

WT98 PLC

ABB 5STPO8F6500 PLC

1MRB150083R1/E ABB CPU

ABB HESG441633R0001 I/O

HESG324258R3 ABB PLC

ABB HESG324015R1/K

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922