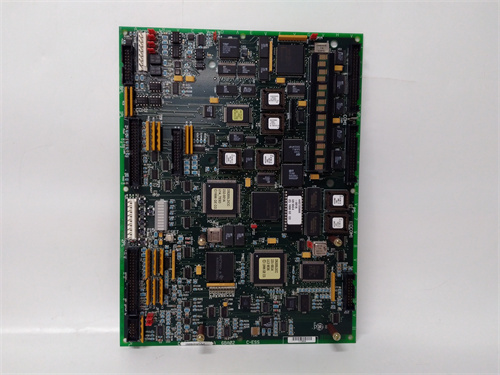

الوصف

Product Name

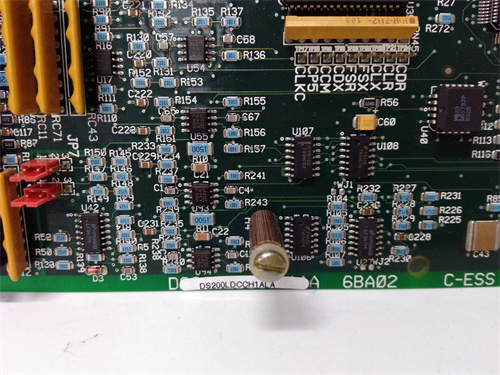

GE + DS200LDCCH1ALA and DS200LDCCH1AGA

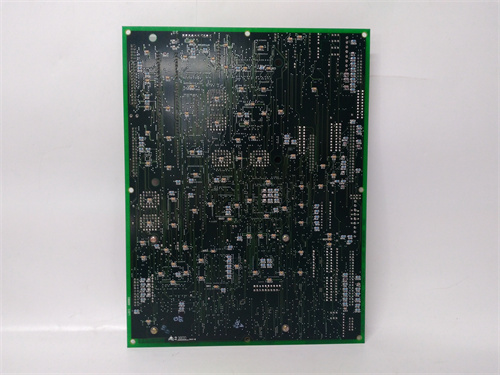

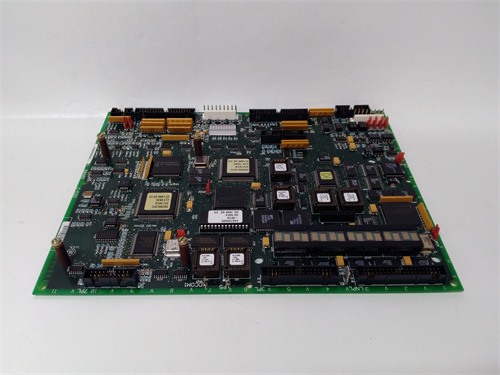

Product Description

The GE + DS200LDCCH1ALA and DS200LDCCH1AGA are integral components of the GE Speedtronic Mark VI control systems. These devices are specifically designed to provide superior control and protection for gas and steam turbines, ensuring optimal performance and reliability in various industrial applications. The DS200LDCCH1ALA is particularly noted for its enhanced diagnostics and operability, while the DS200LDCCH1AGA offers robust communication capabilities and modular functionality. With advanced features and a compact design, these models facilitate seamless integration into existing systems, making them a preferred choice among automation professionals.

Product Specifications

- Model: GE + DS200LDCCH1ALA

- Input Voltage: 28 V DC

- Current: 0.5 A

- Operating Temperature: -40°C to +85°C

- Communication Protocol: Ethernet, Serial

- Model: DS200LDCCH1AGA

- Input Voltage: 24 V DC

- Current: 0.3 A

- Operating Temperature: -40°C to +75°C

- Communication Protocol: Serial, Modbus

Advantages and Features

- Reliability: Both the GE + DS200LDCCH1ALA and DS200LDCCH1AGA are engineered for high durability and extended service life, even in challenging environments.

- Scalability: These models support a modular architecture, allowing for easy expansion and upgrades.

- Advanced Diagnostics: Equipped with sophisticated self-diagnostic features, these devices help in proactive maintenance and quick fault identification.

- Versatile Communication Options: They support multiple protocols, which ensures compatibility with a wide range of industrial systems.

Application Areas and Use Cases

The GE + DS200LDCCH1ALA and DS200LDCCH1AGA are widely utilized in industries such as:

- Oil and Gas: For turbine control and monitoring in offshore and onshore applications.

- Power Generation: Ensuring efficient and safe operation of combined cycle power plants.

- Manufacturing: Automation of turbine-related processes for improved efficiency.

Use Cases

- Power Plant Operation: Utilizing the GE + DS200LDCCH1ALA to control turbine speeds and monitor performance metrics in a gas-fired power plant.

- Industrial Automation: Implementing the DS200LDCCH1AGA in a manufacturing facility for controlling rotary equipment.

Competitive Comparison

When compared to other brands, the GE + DS200LDCCH1ALA and DS200LDCCH1AGA stand out for their:

- Enhanced diagnostic capabilities, which many competitor products lack.

- Superior build quality and temperature ratings that enable operational reliability.

- More comprehensive communication features that facilitate easy integration into existing automation systems.

Selection Advice

- Consider the specific operational environment and requirements of your application. If you require enhanced diagnostics and a robust communication interface, the GE + DS200LDCCH1ALA may be the better choice.

- For applications that prioritize compactness and moderate temperature ranges, the DS200LDCCH1AGA could be more suitable.

- Always evaluate compatibility with existing systems and anticipated scalability needs.

Important Notes

- Ensure proper installation and configuration to fully leverage the capabilities of the GE + DS200LDCCH1ALA and DS200LDCCH1AGA.

- Regular maintenance and updates are required for optimal performance and longevity.

We are your trusted partner, offering models including GE + DS200LDCCH1ALA and DS200LDCCH1AGA, along with other automation spare parts for sale and technical support. We provide you with special discount prices. Please contact us, and we will be more than happy to assist you.

GE+DS200LDCCH1ALA DS200LDCCH1AGA

BENDER IRDH375B-435

A-B MVI56E-MNETC

BENDER IRDH375B-435

PR0S0FT MVI56E-SIE

EMERSON IPMC7616E-002

EMERSON IPMC7616E-002

ATOS AGMZO-REB-P-NP-32/315

SCHNEIDER 140CPU65150

SIEMENS 1FK7105-2AF71-1UA0-Z N05

EPRO MMS3120/022-000

ABB DSQC1018

ABB LDMUI-01

SIEMENS A5E00730540

GE IC693CPU374

RELIANCE MD-B6027C

A-B 1756-L71

A-B 22C-D088A103

HONEYWELL 51198947-100

YASKAWA JZNC-XIU01B

PROSOFT MVI56-MCMR

A-B 22C-D088A103

GE IC695CPU320

ABB CI858K01

BENTLY NEVADA 3500/33

HONEYWELL CC-PCNT01

ABB CP450-T-ETH

ABB 3HAC025338-006

ABB 3HAC025338-006

A-B 1326AB-B515E-21

ABB DSSR122 48990001-NK

ABB DSSR122 48990001-NK

三菱 Q173CPU

A-B 1394-SJT05-C-RL

A-B 1394-SJT05-C-RL

ABB 3HAC025338-006

ROCKWELL AUTOMATION T9110

TRICONEX 3008

A-B 2711P-T7C4D8

Kollmorgen 6SM77K-3.000

ZIPPE MWS10/A

RELIANCE WR-D4004

ABB PM861AK01

YASKAWA LASC-100W8

DEIF SCM4.2

NI PXI-7852R

ABB DSAI130A

KONTRON CP307

TEL TVB6002-1/IMC 1381-644857-16

MECS CS-1000

GE IC698CPE010-AA

“MODICON

” “AS-B838-016

REXROTH MSK040C-0600-NN-M1-UP1-NSNN

A-B 1756-L72

ALLEN BRADLEY 80026-173-23-R MOX12-P3509

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922