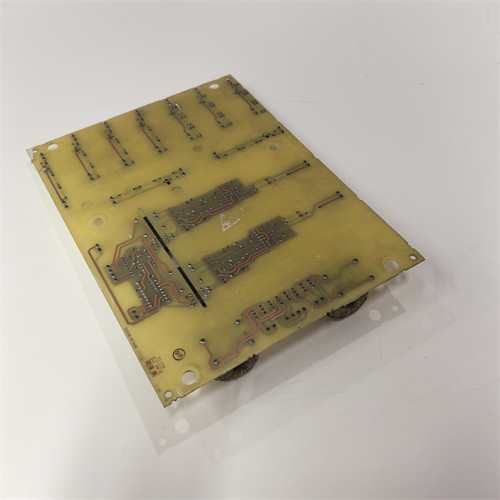

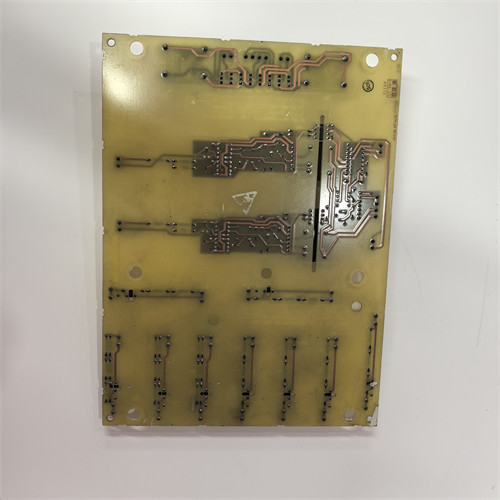

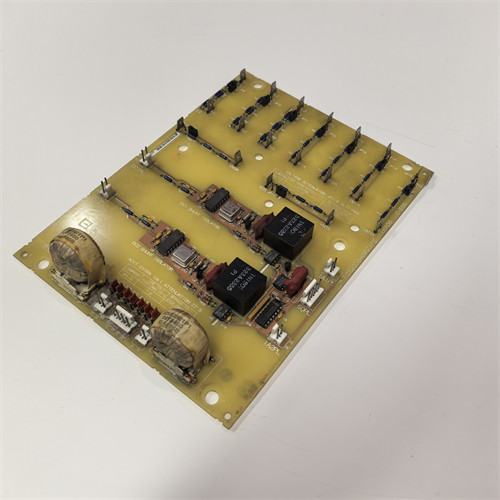

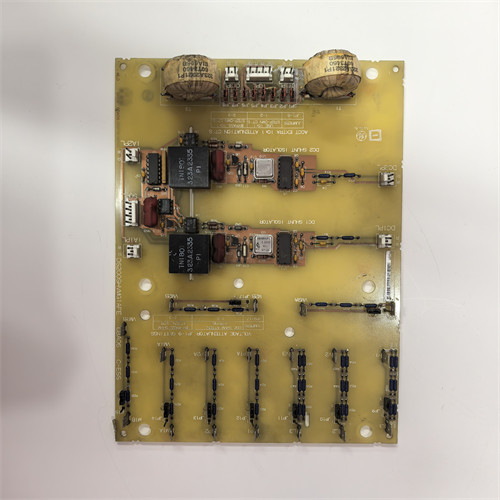

الوصف

Product Name

GE DS200SHVMG1AFE – High-Performance Servo Drive Module

Product Description

The GE DS200SHVMG1AFE represents GE’s cutting-edge servo drive technology, designed for demanding motion control applications in industrial automation. As part of GE’s Mark VIe series, the DS200SHVMG1AFE delivers exceptional precision and dynamic response, making it ideal for complex automation systems. The GE DS200SHVMG1AFE features advanced control algorithms that ensure smooth operation even in high-speed applications. With its rugged industrial design, the DS200SHVMG1AFE maintains reliable performance in harsh environments, offering superior protection against electrical noise and vibration.

Product Parameters

- GE+DS200SHVMG1AFE

- Power Rating: 5-15 kW (configurable)

- Input Voltage: 380-480V AC (±10%), 3-phase

- Output Current: Continuous 32A, Peak 64A (10 sec)

- Control Bandwidth: 2.5 kHz velocity loop

- Feedback Interfaces:

- 20-bit absolute encoder input

- Resolver input (standard)

- SSI and EnDat 2.2 compatible

- Communication Protocols:

- EtherCAT (100Mbps)

- PROFINET IRT

- CANopen (DS402)

- Protection Features:

- Overcurrent (electronic and thermal)

- Overvoltage/Undervoltage

- Short-circuit protection

- Motor thermistor input

- Environmental Specifications:

- Operating Temperature: -20°C to +55°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5-95% non-condensing

- Vibration Resistance: 5g (10-2000Hz)

- Shock Resistance: 15g (11ms)

Advantages and Features

- Precision Control: The GE DS200SHVMG1AFE delivers industry-leading ±1 arc-minute positioning accuracy, enabled by its 20-bit encoder interface and advanced control algorithms.

- Dynamic Performance: With a velocity loop bandwidth of 2.5 kHz and acceleration rates up to 50,000 rpm/s, the DS200SHVMG1AFE outperforms comparable drives in high-speed applications.

- Network Integration: The drive’s multi-protocol support (EtherCAT, PROFINET IRT, CANopen) allows seamless integration with various automation architectures.

- Condition Monitoring: Built-in vibration analysis and motor temperature monitoring enable predictive maintenance, reducing unplanned downtime.

- Safety Features: Complies with SIL3/PLe safety standards, including safe torque off (STO) and safe stop functions.

- Compact Design: Despite its high power rating, the GE DS200SHVMG1AFE features a space-saving design with only 200mm width for 15kW models.

Application Fields and Use Cases

The GE DS200SHVMG1AFE excels in demanding motion control applications across multiple industries:

1. Robotics:

- Used in articulated robots for automotive assembly lines

- Enables high-speed pick-and-place operations with payloads up to 50kg

- Case Study: Implemented in a automotive welding line, achieving 0.1mm repeatability at 2m/s operation

2. Machine Tools:

- Powers high-speed spindles (up to 30,000 RPM) in 5-axis CNC machines

- Enables precision grinding operations with surface finishes <0.2μm Ra

3. Packaging Machinery:

- Drives rotary cutters and form-fill-seal machines at speeds up to 1,200 packages/minute

- Maintains synchronization accuracy within ±0.01° in continuous motion applications

4. Semiconductor Manufacturing:

- Controls wafer handling robots in cleanroom environments

- Achieves sub-micron positioning accuracy for chip bonding applications

Competitor Comparison

When compared to similar servo drives in its class:

| Feature | GE DS200SHVMG1AFE | Siemens S210 (1FK2) | ABB ACS880 | Yaskawa SGD7S |

|---|---|---|---|---|

| Control Bandwidth | 2.5 kHz | 1.6 kHz | 1.2 kHz | 1.8 kHz |

| Encoder Resolution | 20-bit | 18-bit | 17-bit | 19-bit |

| Safety Certification | SIL3/PLe | SIL2/PLd | SIL2 | SIL3 |

| Network Protocols | 3+ | 2 | 2 | 1 |

| Peak Current | 200% (60s) | 300% (3s) | 250% (10s) | 350% (1s) |

Key Advantages of DS200SHVMG1AFE:

- Superior control performance for high-dynamic applications

- Broader protocol support for flexible system integration

- Higher safety certification level

- Better suited for continuous high-load operations

Selection Advice

When specifying the GE DS200SHVMG1AFE:

- Power Requirements:

- Calculate peak and continuous current needs based on motor specifications

- Consider duty cycle requirements (S1, S2, etc.)

- Allow 20% headroom for future upgrades

- Motion Profile:

- Analyze acceleration/deceleration requirements

- Verify positioning accuracy needs

- Consider regenerative energy requirements

- System Integration:

- Confirm network protocol compatibility

- Check available space for heat dissipation

- Plan for proper cable routing and shielding

- Environmental Factors:

- Assess ambient temperature range

- Consider vibration and shock levels

- Evaluate IP protection requirements

Precautions

- Installation:

- Maintain minimum clearance (50mm top/bottom, 30mm sides) for proper cooling

- Use only shielded cables for power and feedback connections

- Ensure proper grounding (separate power and signal grounds)

- Commissioning:

- Always perform auto-tuning procedure with actual load connected

- Verify all safety functions before operation

- Gradually increase torque limits during initial testing

- Maintenance:

- Monitor heat sink temperatures regularly

- Check for abnormal vibrations or noises

- Keep ventilation paths clear of obstructions

- Troubleshooting:

- Utilize built-in oscilloscope function for diagnostics

- Document parameter settings before making changes

- Consult GE technical support for complex issues

We are your trusted automation partner, specializing in the GE DS200SHVMG1AFE and other industrial control components. Our experts provide comprehensive technical support and competitive pricing. Contact us today for special discount offers and customized solutions tailored to your application requirements. Let us help you optimize your motion control systems with genuine GE automation products.

GE+DS200SHVMG1AFE

| MOTOROLA MVME 374-1 |

| MOOG SM3430D-DNASM5 |

| GE IC695CRU320 PLC |

| GE VMIACC-5595-208 PLC |

| BENTLY 1900/65A-00-02-01-01-01 |

| GE WESDAC D20ME PLC |

| A-B 1785-L80E PLC |

| Rexroth HZF01.1-W045N PLC |

| WAVECREST DTS-2079 |

| GE IS220PDIOH1B PLC |

| A-B 1756-L74 PLC |

| ABB KUC711AE101 PLC |

| FLENDER Z148-MN160MB4E PLC |

| A-B 6180P-15BPXP |

| TOSHIBA UTLH21 PLC |

| GE IS200TBAIH1C PLC |

| WOODWARD 9907-164 PLC |

| Rexroth FWA-PPCR0*-GP*-09VRS-MS-P2XXXXPPC-R02.2N-N-NN-P2-NN-FW |

| SCHNEIDER 140CPU67861 |

| REXROTH VDP40.2DEN-G4-NN-NN 15 PLC |

| SCHNEIDER 140CPU67160C PLC |

| ROCKWELL AUTOMATION T8403 |

| FANUC A06B-0373-B675#7075 PLC |

| Rexroth HZF01.1-W045N PLC |

| ABB DSDP140B PLC |

| Rexroth MHD071B-035-PP1-UN PLC |

| SCHNEIDER 140CPU67160 PLC |

| A-B 6181P-15TPXP PLC |

| GE VMIVME-3122 |

| A-B 2711E-K14C6X/E |

| A-B 2711P-B15C4A8 PLC |

| Motorola MVME2100 PLC |

| ABB SPNPM22 |

| Siemens MN160L4E PLC |

| SCHUMACHER ATCS-15 PLC |

| NI PCI-6115 PLC |

| ICS TRIPLEX T8461 |

| TRICONEX 3805E |

| Motorola MVME 374-1 PLC |

| KOLLMORGEN SERVOSTAR610 10A |

| GE BJZCAT868-1 |

| SEIDEL 4KS-M240/20 PLC |

| ABB UDC920BE PLC |

| Rexroth SF-A3.0093.060-10.000 PLC |

| MOOG CPU-30ZBE PLC |

| SIEMENS MOORE MBI/MNI(16413-15) PLC |

| TRICONEX 3805E PLC |

| Bently 3500/22M138607-01 |

| SIEMENS 6SE6430-2AD35-5FA0 PLC |

| MOTOROLA MVME162PA-344E |

| MOTOROLA MVME162PA-344SE PLC |

| ICS T8231 PLC |

| ABB 5SHX2645L0004 PLC |

| GE D20ME-VME PLC |

| A-B 80026-044-06-R PLC |

| ABB 3HAC025527-004 |

| ABB 5SHX2645L0004 PLC |

| PIONEER MAGNETICS PM3328B-6-1-3-E PLC |

| MOTOROLA MVME2400-0351-MPC750 |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922