GE+DS200SHVMG1AGE is a highly specialized PLC spare part developed by GE, a renowned leader in automation technology. It plays a crucial role in enhancing the functionality and reliability of PLC systems across various industrial applications.

GE+DS200SHVMG1AGE

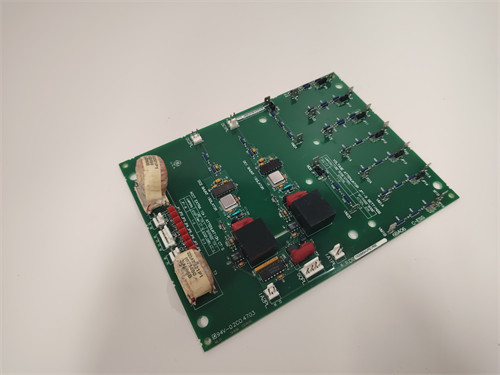

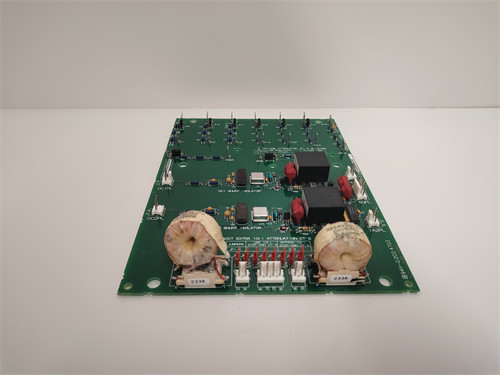

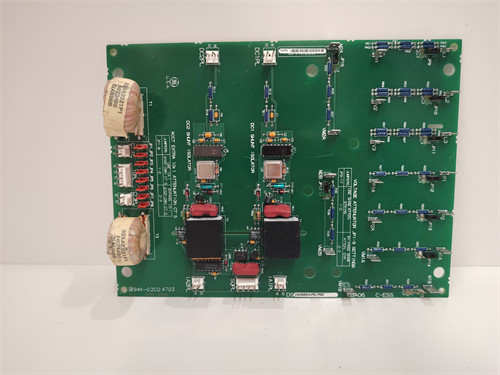

The GE+DS200SHVMG1AGE is an advanced printed circuit board designed to meet the demanding requirements of modern industrial automation. As a key component in GE’s automation product lineup, GE+DS200SHVMG1AGE offers seamless integration with existing PLC architectures, facilitating efficient data processing and control. It is engineered to operate stably under diverse environmental conditions, making it suitable for use in harsh industrial settings, from dusty manufacturing plants to high – humidity facilities.

This model features a robust design that ensures long – term durability. GE+DS200SHVMG1AGE is equipped with state – of – the – art processing capabilities, enabling it to handle complex control algorithms with ease. It also has a wide range of input and output interfaces, allowing for connection to multiple sensors, actuators, and other devices. The board’s modular design simplifies maintenance and upgrades, ensuring that it can adapt to evolving automation needs. Additionally, GE+DS200SHVMG1AGE comes with built – in diagnostic functions, which help in quickly identifying and resolving any issues, reducing downtime and improving overall system efficiency.

- GE+DS200SHVMG1AGE

- Power Supply: AC 90 – 264V, 47 – 63Hz

- Dimensions: 230mm x 150mm x 50mm

- Weight: Approximately 1.5kg

- Operating Temperature Range: – 20°C to + 60°C

- Digital Inputs: 32 channels

- Digital Outputs: 16 channels

- Analog Inputs: 8 channels

- Analog Outputs: 4 channels

- Data Processing Speed: Up to 0.15μs per instruction

One of the primary advantages of GE+DS200SHVMG1AGE is its high reliability. Backed by GE’s extensive engineering expertise, this board is built to last, minimizing the need for frequent replacements. Its high – speed data processing capabilities ensure that it can handle real – time control tasks with precision, improving the overall performance of the PLC system.

The wide range of input and output options on GE+DS200SHVMG1AGE provides great flexibility in system design, allowing users to customize their automation setups according to specific requirements. The built – in diagnostic tools not only save time during troubleshooting but also contribute to proactive maintenance, preventing potential system failures. Moreover, its compatibility with a variety of communication protocols makes it easy to integrate into different network architectures, enabling seamless communication between different components of the automation system.

GE+DS200SHVMG1AGE finds extensive use in multiple industries. In the energy sector, it is employed to control power generation processes in power plants, monitor and regulate the distribution of electricity, and manage the operation of electrical substations. For example, in a large – scale thermal power plant, GE+DS200SHVMG1AGE was used to precisely control the steam turbine speed, resulting in a 10% increase in power generation efficiency.

In the manufacturing industry, it is used to automate production lines. A leading automotive manufacturing plant utilized GE+DS200SHVMG1AGE to manage the robotic assembly process, ensuring accurate and consistent vehicle production. This led to a significant reduction in production errors and an increase in the production rate by 15%. Additionally, it is applied in the chemical industry for controlling chemical reactions, monitoring process variables such as temperature, pressure, and flow rate, and ensuring safe and efficient production.

Compared to competing products, GE+DS200SHVMG1AGE stands out with its wider operating temperature range, making it more adaptable to extreme working environments. It also offers a higher density of input and output channels, allowing for more comprehensive system control without the need for additional expansion modules. In terms of data processing speed, GE+DS200SHVMG1AGE outperforms many of its competitors, enabling faster response times in real – time control applications.

GE’s strong global technical support network also gives GE+DS200SHVMG1AGE an edge. Unlike some competitors, GE provides detailed documentation, regular software updates, and prompt after – sales service, ensuring that users can maximize the performance and lifespan of the product.

When selecting GE+DS200SHVMG1AGE, users should first assess their specific automation requirements. Calculate the exact number of required digital and analog inputs and outputs based on the number of sensors, actuators, and other devices in the system. Consider the environmental conditions where the board will be installed, as the operating temperature and humidity can impact its performance.

Also, evaluate the communication requirements of your system. Ensure that GE+DS200SHVMG1AGE‘s supported communication protocols match those of other components in the network. If future system expansion is anticipated, choose a configuration that offers room for growth, such as additional unutilized input/output channels or expansion slots.

When handling GE+DS200SHVMG1AGE, always ensure that the power supply is disconnected to prevent electrical shock and damage to the board. Wear appropriate electrostatic – discharge (ESD) protection equipment, as the sensitive electronic components on the board can be easily damaged by static electricity.

During installation, follow the manufacturer’s instructions carefully to ensure proper connections. Regularly perform maintenance checks, including inspecting for loose connections, cleaning the board to prevent dust accumulation, and checking the integrity of all components. Keep the product’s documentation handy for reference during operation, troubleshooting, and maintenance.

We are your trustworthy partners. We offer the sales of GE+DS200SHVMG1AGE and other automation spare parts, along with technical support. Enjoy special discounted prices. Contact us, and we will wholeheartedly serve you.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922