الوصف

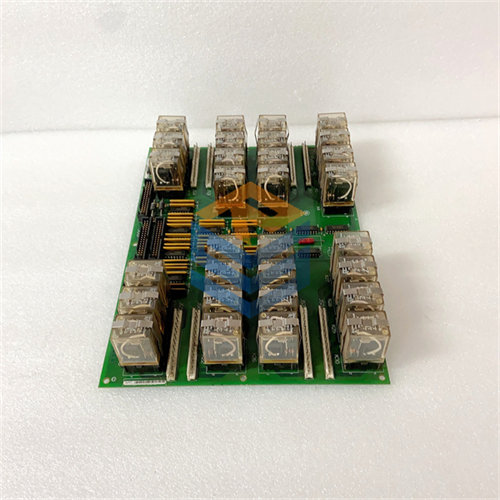

GE DS200TCRAG1ACC DCS PLC Module

The GE DS200TCRAG1ACC is a key component in General Electric’s range of Distributed Control System (DCS) and Programmable Logic Controller (PLC) modules, designed for high-performance industrial automation and process control. The module is typically used in power generation, petrochemical, manufacturing, and energy management systems where robust, reliable control is essential.

Product Name:

GE DS200TCRAG1ACC DCS/PLC Module

Product Description:

The GE DS200TCRAG1ACC module is part of General Electric’s Mark V and Mark VIe control systems, which are used in various gas turbine control and industrial process automation applications. The module is designed to handle real-time control, data acquisition, and fault detection tasks in systems requiring high availability and precision. It integrates seamlessly into GE’s control architecture, making it a critical component for mission-critical applications.

This module typically features flexible I/O, advanced diagnostics, and redundant design features to ensure operational continuity in complex industrial settings. It is specifically used in applications where high-speed data processing, safe operation, and fault-tolerant design are needed.

Key Features:

-

Real-Time Performance:

- Designed to handle high-speed data processing and real-time control for industrial automation systems.

- Provides quick response times for critical control loops, ensuring system stability.

-

Redundant Architecture:

- Supports redundant power supplies, communication paths, and I/O connections to ensure reliability and uptime.

- Helps prevent single points of failure and enhances system fault tolerance.

-

Integrated Communication:

- Supports various communication protocols, including Ethernet/IP, Modbus, and Profinet, making it easy to integrate with SCADA systems, other PLCs, and field devices.

- High-speed communication ensures timely data exchange across the system for coordinated control.

-

Flexibility in I/O Configurations:

- Provides a variety of analog and digital I/O options, allowing for custom configuration depending on application requirements.

- Capable of handling high-frequency inputs for precise control of industrial machinery.

-

Safety Features:

- Equipped with self-diagnostics for continuous monitoring of the system’s health.

- Built-in alarm reporting and fault detection capabilities for proactive issue resolution.

-

Easy Integration:

- Compatible with other GE control systems (such as Mark VIe), enabling seamless integration into existing control systems.

- Easily configurable through GE’s proprietary software tools.

-

Programmability:

- Can be programmed using GE’s development environments, providing flexibility in creating custom control strategies and logic.

- Offers extensive functionality for process control and protection.

-

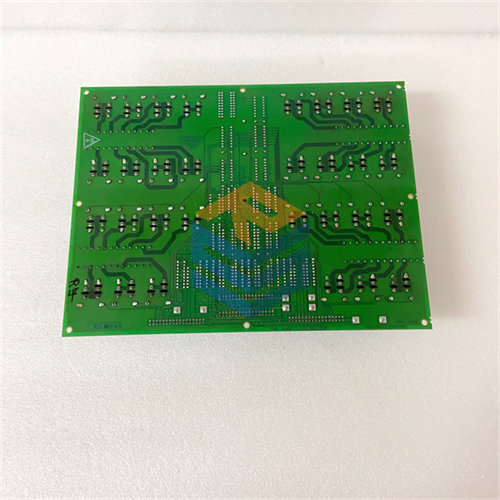

Durable Design:

- Built for use in harsh industrial environments with protection against environmental factors such as temperature, humidity, and vibration.

Product Parameters and Specifications:

Electrical & Power Requirements:

- Operating Voltage: Typically 24V DC.

- Power Consumption: Dependent on the configuration, typically varies based on the number of connected devices and modules.

- Redundant Power Supply: Supports redundancy to ensure the system continues to operate during power failures.

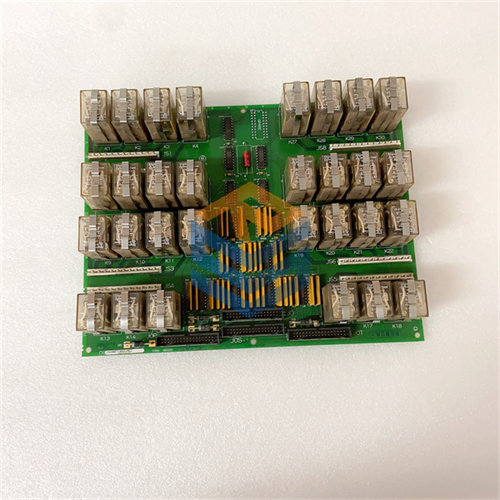

I/O Configuration:

- Analog Inputs: Supports various types of 4-20mA or 0-10V analog inputs.

- Digital Inputs/Outputs: Capable of handling discrete signals from switches, relays, or sensors.

- Relay Outputs: Available for controlling machinery or triggering emergency shutdowns.

- High-Speed I/O: Capable of handling high-frequency inputs/outputs for fast-response control loops.

Communication Protocols:

- Modbus RTU/TCP, Ethernet/IP, Profinet for communication with SCADA systems and other industrial devices.

- Serial Communication Ports: Typically includes RS-232/RS-485 ports for communication with field devices or remote stations.

- Redundant Ethernet Ports: For ensuring continuous communication and fault-tolerant network connections.

Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -20°C to 85°C (-4°F to 185°F).

- Relative Humidity: 5% to 95% (non-condensing).

- Vibration Resistance: Designed to withstand industrial-grade vibrations.

Physical Specifications:

- Dimensions: Standard rack-mounted form factor (dimensions may vary depending on the configuration).

- Weight: Dependent on the number of modules and configuration but generally within the range of 2 to 5 kg.

Diagnostics & Maintenance:

- Self-Diagnostics: Continuous system health monitoring and fault detection.

- Event Logging: Logs diagnostic events and alarms to facilitate troubleshooting.

- Alarm Reports: Provides detailed reports for easy identification of system anomalies and failures.

Programming & Configuration:

- Development Environment: Programmed using GE’s control software, such as ControlST or Mark VIe tools, for ease of configuration.

- Custom Logic: Supports programming in structured text, function block diagram (FBD), and ladder logic for customized control and automation strategies.

Safety & Protection:

- Failsafe Mechanism: Built-in protection algorithms to ensure safe shutdowns in case of failures or anomalies.

- Redundant Communication Paths: Helps ensure communication reliability even during network failures.

Applications:

-

Power Generation:

- The GE DS200TCRAG1ACC module is commonly used in gas turbine control, providing precise control over turbine start/stop cycles, speed regulation, and fuel flow.

-

Industrial Automation:

- Used for managing automated production lines, robotic arms, and process machines that require real-time control and monitoring.

-

Oil & Gas:

- Employed for wellhead control, drilling rig automation, and pipeline monitoring in the oil and gas sector.

-

Manufacturing & Petrochemical Plants:

- Helps in controlling and monitoring critical process parameters such as pressure, flow, and temperature in complex petrochemical operations.

-

Renewable Energy:

- Used in wind and solar farms to monitor system performance and ensure optimal energy production.

Conclusion:

The GE DS200TCRAG1ACC DCS/PLC Module is a powerful, reliable, and flexible control module designed for demanding industrial automation and process control applications. With its redundant architecture, advanced diagnostics, and high-speed communication capabilities, it is well-suited for use in power generation, oil and gas, manufacturing, and petrochemical industries. Whether used for turbine control, factory automation, or safety-critical applications, the DS200TCRAG1ACC provides the reliability and precision required for complex, high-performance systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922