الوصف

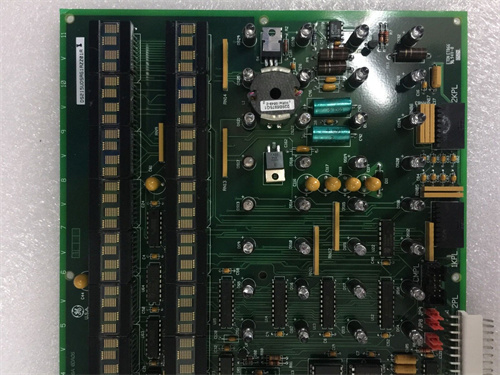

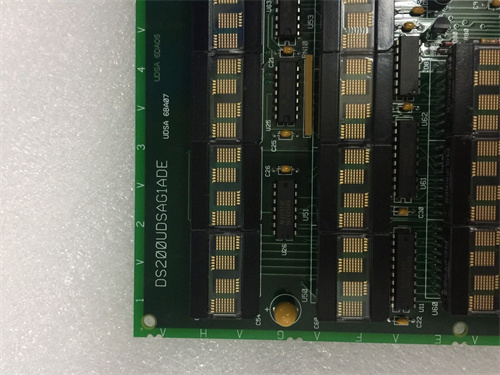

GE DS200UCPBG6AFB DCS/PLC Module

The GE DS200UCPBG6AFB is a part of General Electric’s control system family, specifically designed for Distributed Control System (DCS) and Programmable Logic Controller (PLC) applications in industrial automation. This module is integral to GE’s Mark VIe control system, and it serves a critical role in process control, system monitoring, and real-time data processing. It is typically used in industries such as power generation, oil and gas, manufacturing, and chemical processing, where high availability, reliability, and rapid response are essential.

Product Name:

GE DS200UCPBG6AFB DCS/PLC Module

Product Description:

The GE DS200UCPBG6AFB is a Universal Control Processor module that provides high-performance control for industrial automation systems. It is part of the Mark VIe system and designed to work with GE’s industrial control systems for managing complex processes. The module supports high-speed processing for real-time control and monitoring of plant operations, offering built-in features for fault detection, diagnostics, and system health monitoring.

This Universal Control Processor (UCP) is engineered to offer flexibility in configuration and scalable control, making it suitable for a wide range of industrial applications, including turbine control, flow and pressure regulation, automation of manufacturing processes, and energy management systems. Its modular architecture ensures that it can be easily integrated into existing control systems, making it a valuable component in any high-performance control application.

Key Features:

-

Real-Time Control:

- Capable of handling high-speed data processing and real-time control tasks, allowing rapid responses to system events.

-

Flexible I/O Configuration:

- Offers extensive options for digital, analog, and relay I/O, providing flexibility in system design.

-

Integrated Communication:

- Supports various communication protocols, including Ethernet/IP, Modbus, Profinet, and RS-232/RS-485, enabling seamless communication with other systems and devices.

-

Advanced Diagnostics:

- Equipped with self-diagnostics, it continuously monitors system performance, providing real-time feedback on system health.

- Offers fault detection and alarm reporting, reducing downtime and simplifying maintenance.

-

Redundancy:

- Designed with redundancy features to ensure high availability, including redundant power supplies, communication paths, and I/O connections, reducing the risk of system failure.

-

Durable Design:

- Built to withstand the harsh environments typically encountered in industrial settings, including temperature extremes, humidity, and vibration.

-

Programmability:

- Can be programmed using GE’s proprietary software tools, such as ControlST, for creating custom control strategies and logic tailored to specific industrial needs.

-

Modular Architecture:

- Can be easily expanded or modified to fit the growing needs of the plant, offering scalability and flexibility.

Product Parameters and Specifications:

Electrical & Power Requirements:

- Operating Voltage: Typically 24V DC.

- Power Consumption: Power usage will vary depending on the configuration and connected peripherals but typically falls within 10-40 W for the control module.

- Redundant Power Supply: Supports redundant power input, ensuring continuous operation even in the event of a power supply failure.

I/O Configuration:

- Analog Inputs: Typically supports 4-20mA or 0-10V analog input signals, suitable for a range of sensors.

- Digital Inputs/Outputs: Handles discrete signal inputs from sensors, switches, or other field devices, as well as controlling outputs for various actuators.

- Relay Outputs: Used for controlling devices such as pumps, motors, or alarms.

- High-Speed I/O: Capable of processing high-frequency signals for critical control loops, such as turbine speed regulation or pressure control.

Communication Protocols:

- Ethernet/IP, Modbus RTU/TCP, Profinet for communication with SCADA systems, other PLCs, and field devices.

- Serial Communication Ports: Includes RS-232/RS-485 for communication with field devices.

- Redundant Ethernet Ports: Offers dual Ethernet ports for enhanced reliability and fault tolerance in network communications.

Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -20°C to 85°C (-4°F to 185°F).

- Relative Humidity: Designed to operate in environments with 5% to 95% relative humidity (non-condensing).

- Vibration Resistance: Meets industrial standards for vibration and mechanical shock, ensuring reliability in demanding environments.

Physical Specifications:

- Dimensions: Standard rack-mounted module with dimensions typically around 19″ rack width and 3U height (exact dimensions may vary depending on configuration).

- Weight: Approximately 2.5 kg to 5 kg, depending on configuration.

Diagnostics & Maintenance:

- Self-Diagnostics: Continuously monitors module health and performance.

- Event Logging: Logs alarms, diagnostic events, and system faults for troubleshooting and performance analysis.

- Alarm Reporting: Offers real-time alarm notifications to alert operators about potential issues or failures.

Programming & Configuration:

- Development Environment: Uses ControlST and other GE proprietary tools for programming and configuring the module.

- Programming Languages: Supports structured text, ladder logic, and function block diagram programming, offering flexibility for custom automation strategies.

Safety & Protection:

- Failsafe Mechanisms: Includes built-in safety features such as emergency shutdown logic and failover to redundant systems in the event of failure.

- Redundant Communication: Built-in redundancy for network communication and I/O connections to prevent data loss or interruption in control.

Applications:

-

Power Generation:

- Used in gas turbine control systems to monitor and regulate parameters such as turbine speed, fuel flow, and temperature.

-

Oil & Gas:

- Employed for automation of drilling rigs, pipeline monitoring, and wellhead control systems to ensure safe and efficient operation.

-

Manufacturing & Chemical Processing:

- Controls industrial processes such as flow, pressure, temperature, and level in petrochemical, food processing, and chemical manufacturing facilities.

-

Renewable Energy:

- Used in wind farms, solar farms, and energy storage systems to optimize performance and ensure safe operation.

-

Water Treatment:

- Applied in water treatment plants for managing critical parameters like flow, pressure, and chemical dosing.

Conclusion:

The GE DS200UCPBG6AFB DCS/PLC Module is a highly reliable and versatile control processor module, designed to offer high-performance control for a range of industrial automation systems. With redundancy features, advanced diagnostics, and real-time communication, it ensures continuous system operation in demanding environments. Whether in power generation, oil and gas, manufacturing, or chemical processing, the DS200UCPBG6AFB module provides the necessary control, reliability, and flexibility needed for high-performance industrial control systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922