الوصف

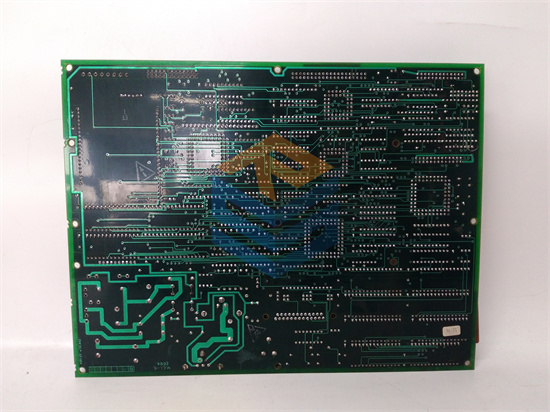

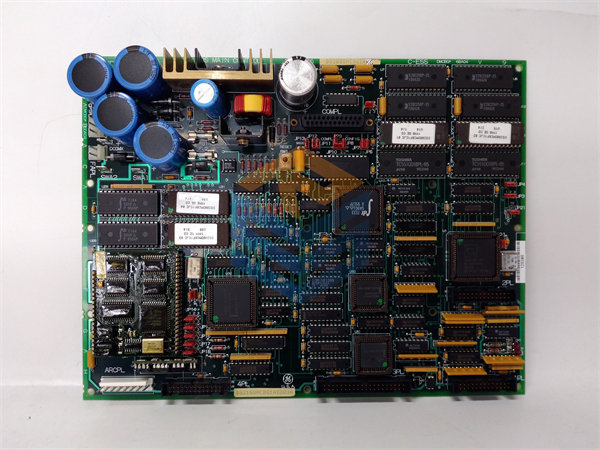

GE+DS215DMCBG1AZZ03A DCS PLC Module

Product Name:

GE DS215DMCBG1AZZ03A – DCS PLC (Distributed Control System Programmable Logic Controller) Module

Product Description:

The GE DS215DMCBG1AZZ03A is a DCS (Distributed Control System) PLC module manufactured by General Electric (GE). It is part of the Mark VIe system used for industrial automation in sectors such as power generation, oil & gas, chemical processing, and manufacturing. This module is designed to manage complex control processes, providing high-performance processing capabilities for real-time control and monitoring of industrial systems.

The DS215DMCBG1AZZ03A module is integral to the GE Mark VIe distributed control system and provides a key interface for integrating field devices, sensors, and other process control systems into a single, cohesive system. It features advanced control strategies, fault detection, diagnostics, and support for various communication protocols, enabling reliable operation and troubleshooting in critical applications.

Product Parameters:

- Model: DS215DMCBG1AZZ03A

- Series: GE Mark VIe DCS

- Type: DCS PLC Module

- Form Factor: Rack-mounted (modular design for flexibility in system configuration)

- Power Supply:

- Typically 24V DC

- Power Consumption: Approximately 30W (varies with configuration)

- Operating Temperature:

- Standard: -40°C to 70°C

- Storage Temperature: -40°C to 85°C

- Relative Humidity: 5% to 95% (non-condensing)

- Dimensions:

- Standard: 6.00″ x 3.50″ x 1.00″ (varies with configuration)

- Weight: ~1 kg (varies with configuration)

Supported Communication Protocols:

- Ethernet/IP: For high-speed network communication with other automation systems.

- Modbus RTU/TCP: For communication with external devices and controllers.

- Fieldbus: Integration with various field devices and I/O systems using FOUNDATION Fieldbus, HART, or Profibus.

- Profinet: For high-speed data exchange with distributed field devices.

- GE Mark VIe Protocol: Proprietary protocol for seamless integration within the GE Mark VIe system.

Product Specifications:

-

Processor:

- Advanced, high-performance microprocessor designed for real-time control of complex industrial processes.

- Dual-core processors for redundancy, ensuring reliability and uptime.

-

Memory:

- RAM: 2 GB (standard) for fast data processing and control algorithms.

- Flash Memory: 8 GB for system configuration, logs, and backup.

- Expandable Memory: Options available for larger or more complex systems.

-

I/O Capability:

- Digital I/O: Supports up to 32 digital inputs and 32 digital outputs.

- Analog I/O: Configurable to support up to 16 analog inputs and 8 analog outputs, depending on the configuration.

- Temperature & Pressure Sensors: Support for a wide range of industrial sensors.

- Fieldbus I/O: Direct support for FOUNDATION Fieldbus, HART, and Profibus devices.

- Redundant I/O: For high-availability applications to prevent failure in critical control systems.

-

Control Functions:

- PID Control: For precise control of industrial processes.

- Fuzzy Logic: Advanced control strategy for non-linear systems.

- Cascade Control: For multi-variable control in complex processes.

- Batch Control: Supports integration with batch processing systems.

- Emergency Shutdown (ESD): Integration with safety systems to shut down critical processes in case of failure.

-

Networking and Communication:

- Ethernet Ports: 1 GB Ethernet for fast, reliable communication between modules and other control systems.

- Redundant Network Paths: Available for high-availability, fault-tolerant systems.

- Web-Based Interface: Remote configuration, monitoring, and diagnostics through a web browser interface.

-

Safety:

- SIL 2/3 Compliance: Safety Integrity Level compliance for critical applications.

- Fail-Safe Operation: Built-in fail-safe mechanisms for system reliability.

- Safety Instrumented Systems (SIS): Integration with SIS for emergency shutdown or safety monitoring.

-

Diagnostics and Monitoring:

- Built-in Diagnostics: Real-time health monitoring and error detection to prevent failures.

- Event Logging: Logs and alarms generated to assist in troubleshooting and fault detection.

- Self-diagnostics: The system automatically checks for errors and corrects faults where possible.

- Predictive Maintenance: Predictive algorithms to anticipate failures and enable proactive maintenance.

-

User Interface:

- GE Mark VIe HMI: Integrated with GE Mark VIe HMI (Human-Machine Interface) for real-time control and monitoring.

- Remote Access: Users can access system diagnostics and control remotely via the web interface.

- Alarm Management: Integrated alarm and event notification system for real-time alerts.

Key Features and Advantages:

-

Scalable System Integration:

- Easily integrates into large-scale automation systems using the GE Mark VIe architecture.

-

High Availability:

- Features redundant configurations for both communication and I/O, ensuring system uptime and preventing unplanned outages.

-

Advanced Control and Monitoring:

- Supports advanced control algorithms, including PID, fuzzy logic, and cascade control, optimizing system performance.

-

Safety Compliance:

- Complies with SIL 2/3 standards, making it suitable for critical safety applications.

-

Comprehensive Diagnostics and Predictive Maintenance:

- The module comes equipped with extensive diagnostic tools that aid in real-time fault detection and predictive maintenance, reducing downtime and improving overall reliability.

-

Real-Time Control and Response:

- Real-time data processing and decision-making enable rapid response to changing conditions, crucial for dynamic industrial environments.

-

Ease of Use:

- User-friendly interfaces, including web access and integration with GE Mark VIe HMI, ensure simplified monitoring and control.

-

Flexible Configuration:

- Supports a wide range of configurations and can be expanded to accommodate growing automation needs.

Applications:

The GE DS215DMCBG1AZZ03A DCS PLC module is used in industries such as:

- Power Generation: Control of turbines, generators, and grid systems in power plants.

- Oil & Gas: Automation of drilling rigs, pipeline monitoring, and refining processes.

- Chemical & Petrochemical: Management of reactors, distillation columns, and chemical production.

- Water & Wastewater: Automation of pumps, filtration, chemical dosing, and system monitoring.

- Pharmaceutical: Control of batch production, mixing, and regulatory processes.

- Manufacturing: Automation of industrial machines and complex manufacturing lines.

Competitive Comparison:

Compared to other DCS modules like those from Honeywell or Emerson, the GE DS215DMCBG1AZZ03A excels in:

- Integration with Mark VIe Platform: Seamless integration within the GE Mark VIe DCS system, providing a unified control and monitoring environment.

- Redundancy Features: Redundant processors, communication paths, and I/O systems provide high reliability for mission-critical applications.

- Predictive Diagnostics: Superior diagnostics and predictive maintenance tools, reducing system downtime.

- Flexible Control: Offers advanced and flexible control strategies that support a wide variety of industrial processes.

The GE DS215DMCBG1AZZ03A DCS PLC module is a versatile, high-performance solution for industrial process automation. Its scalability, advanced control algorithms, and strong integration with the GE Mark VIe DCS make it ideal for demanding applications requiring precision, reliability, and high availability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922