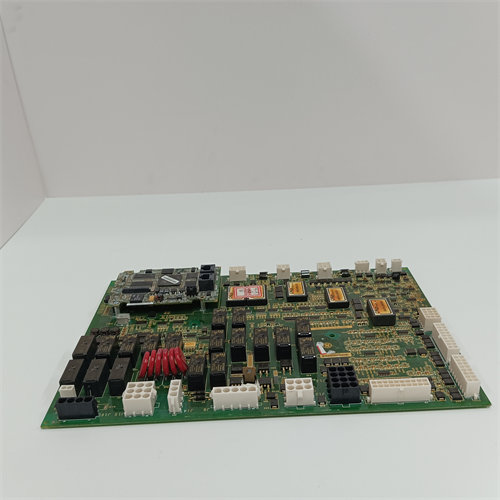

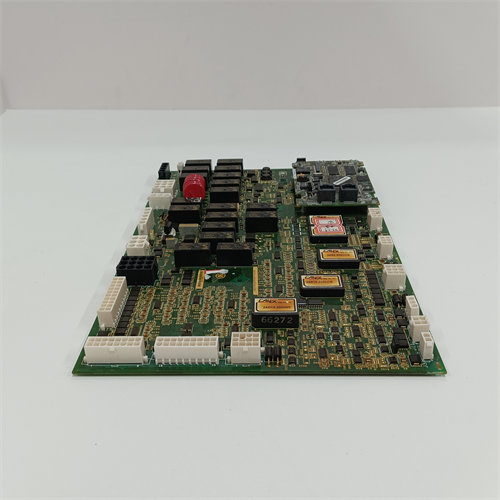

الوصف

GE IS200AEPAH1ACB – DCS PLC Module

The GE IS200AEPAH1ACB is a communications interface module used in GE’s Mark VIe Distributed Control System (DCS) and PLC (Programmable Logic Controller) systems. It is part of General Electric’s (GE) industrial automation solutions, designed for critical applications requiring high availability, precise control, and robust communication between various automation systems. The module ensures real-time data exchange between different control systems, sensors, and actuators.

Product Name:

GE IS200AEPAH1ACB – DCS/PLC Communications Module

Product Description:

The GE IS200AEPAH1ACB is a communications interface module designed for Mark VIe and Mark VI systems in GE’s DCS and PLC-based control systems. This module facilitates communication between the controller and remote I/O devices, field instruments, and other subsystems. It is primarily used in automation and control applications that demand high performance and reliability, such as in power generation, oil and gas, chemical processing, and manufacturing industries.

The IS200AEPAH1ACB module supports both serial and Ethernet communication protocols and integrates with various industrial networks for seamless control system communication. The module is highly reliable, offering diagnostic capabilities and ensuring continuous data exchange even in critical process environments. It helps provide robust and secure communication between controllers, field devices, and operators for efficient plant management.

Key Features:

- Interface for Remote Communication: Connects the Mark VIe system with external equipment and I/O devices via industrial communication protocols like Ethernet, Modbus, and Serial connections.

- Real-time Data Communication: Supports real-time data exchange between control systems and external devices, ensuring high levels of control accuracy and responsiveness.

- Diagnostic and Monitoring Functions: Provides system health diagnostics and communication monitoring, reducing downtime and optimizing system performance.

- Redundant Design: Ensures high availability with redundant communication channels for critical applications.

- Versatile Connectivity: Can communicate with various industrial control devices, sensors, and actuators, providing flexibility for different application requirements.

- Compliance and Safety: Meets industry safety standards for reliable and secure operations in industrial environments.

Product Parameters and Specifications:

1. Model Information:

- Model Number: IS200AEPAH1ACB

- Module Type: Communication Interface Module

- Brand: General Electric (GE)

- System Compatibility: Mark VIe DCS, Mark VI PLC

2. Communication Protocols:

- Ethernet: Supports high-speed Ethernet communication for real-time data exchange.

- Serial Communication: Typically includes RS232/RS485 serial ports for communication with legacy devices and field instruments.

- Modbus TCP/IP: Allows communication with Modbus-compatible devices, ensuring integration with various industrial networks.

- Industrial Fieldbuses: Integration with various industrial networks such as Profibus, DeviceNet, and Modbus RTU.

3. Electrical Specifications:

- Input Voltage: Typically operates on 24V DC, common for GE’s Mark VIe and Mark VI systems.

- Power Consumption: The power consumption is generally low but depends on the operational configuration and connected devices.

- Current Consumption: Approximately 1-2 Amps at 24V DC.

- Isolation: Provides electrical isolation between control system and connected field devices, ensuring safety and preventing electrical interference.

4. Environmental Specifications:

- Operating Temperature: Designed for an industrial temperature range of 0°C to 60°C (32°F to 140°F).

- Storage Temperature: Typically -40°C to 85°C (-40°F to 185°F).

- Humidity: Can operate in environments with 5% to 95% relative humidity (non-condensing).

- Vibration and Shock Resistance: Rated for industrial environments, the module can tolerate standard industrial vibrations and mechanical shocks.

5. Mounting and Integration:

- Rack-Mountable: The module is designed for easy mounting in 19-inch racks for integration into control cabinets or racks.

- Plug-and-Play: The IS200AEPAH1ACB module is typically easy to install and replace, supporting hot-swappable features for minimal downtime.

- Field-Installable: Modules can be installed and maintained in the field, making it easier to upgrade or replace components without requiring a full system shutdown.

6. Diagnostics and Monitoring:

- Built-in Diagnostics: Provides continuous monitoring of communication status and system health. If issues arise, the module sends diagnostic alerts and can be easily diagnosed using the GE control software.

- LED Indicators: Equipped with LED status indicators for monitoring power, communication health, and error conditions.

- Fault Detection: Capable of detecting faults like communication errors, disconnections, and device malfunctions to alert operators and prevent system failures.

7. Certifications and Compliance:

- CE Marking: Complies with European Union safety and EMC (Electromagnetic Compatibility) directives.

- UL Approval: UL-listed versions may be available, ensuring compliance with North American safety standards.

- SIL: Meets Safety Integrity Level (SIL) requirements for integration into Safety Instrumented Systems (SIS) in critical applications.

- RoHS Compliant: The module is RoHS (Restriction of Hazardous Substances) compliant, ensuring that it is environmentally friendly and free of hazardous materials.

8. Physical Specifications:

- Dimensions: Standard 19-inch rack mountable, module dimensions vary depending on specific configuration but are typically around 1U to 2U in height.

- Weight: Approximate weight is around 2-3 kg (depending on configuration).

Applications:

The GE IS200AEPAH1ACB communication module is ideal for industries requiring robust and reliable real-time communication between control systems and external devices. Typical use cases include:

- Power Generation:

- Ensures seamless communication between control systems and field devices in power plants, ensuring safe and efficient operation of turbines, generators, and reactors.

- Oil & Gas:

- Supports communication for remote monitoring and control in upstream, midstream, and downstream oil and gas operations.

- Chemical Processing:

- Facilitates critical communication between safety systems, process control systems, and sensors in chemical plants.

- Manufacturing:

- Integrated into automation systems for production lines, supporting control of robotic systems, material handling, and machine-to-machine communication.

- Water and Wastewater Treatment:

- Monitors and controls critical systems such as pumps, filtration, and chemical dosing, ensuring proper treatment processes.

Conclusion:

The GE IS200AEPAH1ACB is a highly versatile and reliable communication interface module designed for integration into GE Mark VIe DCS and PLC systems. Its ability to support multiple industrial communication protocols, redundant designs, and real-time data exchange makes it a vital component in critical control systems. With its diagnostic capabilities, high availability, and flexible integration options, it ensures that industries such as power generation, oil and gas, and chemical processing maintain continuous, safe, and efficient operations.

This module offers the connectivity needed to handle complex communication needs while ensuring optimal performance and reliability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922