الوصف

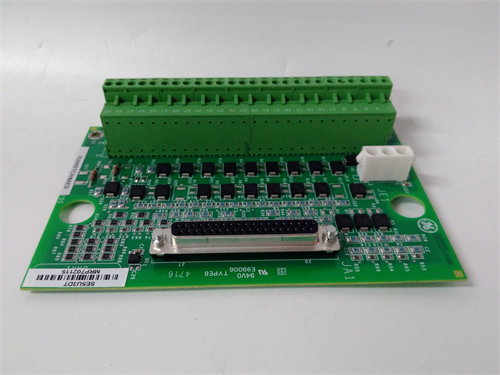

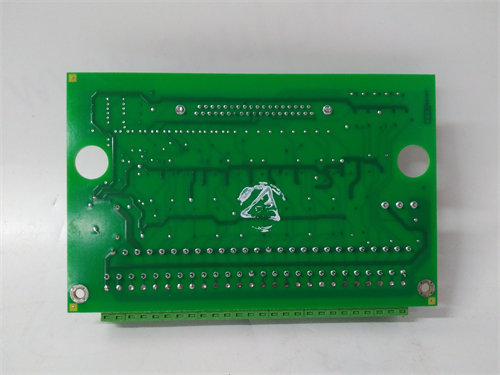

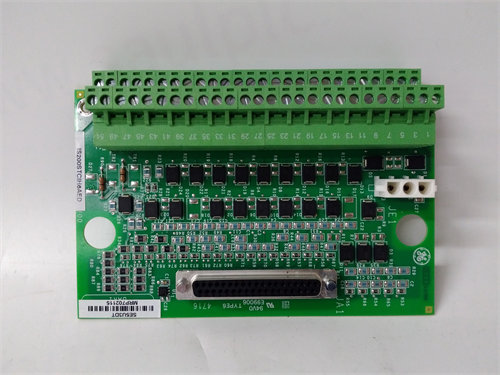

GE IS200STCIH6AED DCS PLC Module

Product Name:

GE IS200STCIH6AED – DCS (Distributed Control System) PLC Module

Product Description:

The GE IS200STCIH6AED is a high-performance Distributed Control System (DCS) PLC module developed by General Electric (GE) as part of the Mark VIe series. This module is specifically designed for use in advanced process control and automation systems, offering exceptional reliability and performance for complex industrial environments. It is widely used in industries such as power generation, petrochemical, manufacturing, and water treatment systems where accurate, real-time control is crucial.

The IS200STCIH6AED module serves as a key component in controlling and monitoring distributed systems, such as turbines, pumps, and motors, with a high degree of precision. The module supports a range of industrial communication protocols and is designed to integrate seamlessly with other GE control systems, ensuring optimal control and monitoring capabilities across a wide array of applications.

Product Parameters:

- Model: IS200STCIH6AED

- Series: Mark VIe series (GE’s Distributed Control System)

- Type: DCS PLC I/O Module

- Form Factor: Rack-mounted (standard)

- Communication Protocols Supported:

- Ethernet TCP/IP

- Modbus

- Profibus DP

- GE’s proprietary communication protocols

- Input/Output Support:

- Digital I/O: 32 Inputs, 32 Outputs (expandable based on system configuration)

- Analog I/O: 16 Inputs, 8 Outputs

- Support for additional field devices (e.g., thermocouples, RTDs)

- Power Supply Requirements:

- 24V DC nominal input

- Power Consumption: Typically 30W (varies depending on module configuration)

- Processor Type:

- High-performance microprocessor-based

- Multi-core architecture

- Memory:

- 1 GB RAM (expandable depending on system needs)

- Flash memory for configuration storage, diagnostics, and system backup

- Environmental Ratings:

- Operating Temperature: 0°C to 70°C

- Storage Temperature: -20°C to 85°C

- Humidity: 5% to 95% (non-condensing)

- Vibration: Designed to meet industrial-grade vibration standards

- EMC: Built to meet industrial EMC (Electromagnetic Compatibility) standards, ensuring minimal interference

Product Specifications:

- Control Capability:

- Real-time control of distributed field devices such as sensors, actuators, and other control elements.

- PID control, logic-based control, and event-driven actions.

- Supports both open-loop and closed-loop control strategies for industrial processes.

- Communication & Networking:

- Ethernet TCP/IP for fast, high-bandwidth communication across large distributed networks.

- Supports redundant communication pathways to ensure reliable, fail-safe operations.

- Integration with SCADA systems for centralized monitoring and control of industrial operations.

- Modbus and Profibus compatibility for integrating third-party devices and systems.

- Diagnostics & Monitoring:

- Advanced system diagnostics for monitoring CPU health, I/O status, and module performance.

- Built-in tools for fault detection, signal integrity checks, and network diagnostics.

- Real-time health monitoring and system alerts to ensure the continuous operation of critical control systems.

- Safety Features:

- Compliance with safety standards such as SIL-3 (Safety Integrity Level 3) for safety-critical applications.

- Emergency shutdown (ESD) support and fail-safe logic for high-risk applications.

- Fault-tolerant design for uninterrupted operations in hazardous environments.

- User Interface & Integration:

- Easy-to-use interface for configuration, diagnostics, and monitoring, accessible via local or remote HMI/SCADA systems.

- Compatible with GE Proficy™ HMI/SCADA software for intuitive visualizations and real-time decision-making.

Key Features and Advantages:

- High Performance: The IS200STCIH6AED offers real-time control with advanced processing capabilities, making it ideal for high-demand industrial applications.

- Scalability: The module is designed to be highly scalable, allowing users to expand or modify the control system as their needs evolve.

- Reliability: GE’s design ensures durability and performance under harsh industrial conditions, including high temperatures, humidity, and vibration.

- Flexible Communication: Supports multiple communication protocols, which enables the module to easily integrate into existing industrial networks.

- Advanced Diagnostics: Provides extensive diagnostic and troubleshooting capabilities, improving the overall efficiency of system maintenance and reducing downtime.

- Safety Integration: Built-in safety features make it suitable for critical applications in industries where process safety is paramount.

Applications:

The IS200STCIH6AED module is typically used in the following industrial sectors and applications:

- Power Generation: Control of turbines, generators, and power distribution systems.

- Oil & Gas: Automation of process control systems, including pipeline monitoring and gas processing plants.

- Water Treatment: Control of pumps, filtration systems, and chemical dosing systems in municipal water treatment facilities.

- Petrochemical: Monitoring and controlling refining processes, chemical reactors, and distillation columns.

- Manufacturing: Used in automated production lines for assembly, packaging, and quality control.

Competitive Comparison:

When compared to other DCS PLC modules, such as those from Siemens (e.g., Siemens PCS 7) or Schneider Electric, the IS200STCIH6AED stands out for its:

- Integrated Diagnostics: Comprehensive monitoring tools and fault detection systems are more advanced than many competing models.

- Seamless Integration: Particularly suited for large-scale, GE-based control systems and environments that require interoperability with older GE systems.

- Real-time Control: Provides exceptionally low-latency control and data acquisition compared to other systems in the same class.

The GE IS200STCIH6AED is a reliable and versatile DCS PLC module that excels in complex industrial environments where high-performance control and system integrity are crucial. It offers the scalability, flexibility, and advanced diagnostics necessary for modern industrial automation systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922