الوصف

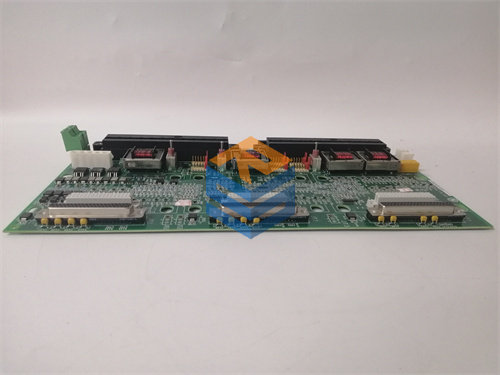

GE IS200TSVOH1BCC DCS PLC Module

Product Name:

GE IS200TSVOH1BCC – Turbine Control System (TCS) I/O Module for GE Distributed Control System (DCS) and Programmable Logic Controller (PLC) Systems

Product Description:

The GE IS200TSVOH1BCC is a Turbine Supervisory I/O (TSI/O) module that is part of GE’s Mark VIe Distributed Control System (DCS) and is typically used in turbine control applications. It is designed to interface between the control system and the turbine’s I/O signals, handling the monitoring and control of critical turbine parameters. This module provides both input and output capabilities, enabling precise control over turbine systems in industries such as power generation, oil & gas, and other energy-related fields.

The IS200TSVOH1BCC module is robust, highly reliable, and equipped with a variety of diagnostic features to ensure smooth operation in demanding environments. It is used for controlling turbine valves, governors, and other turbine-related processes, which require high-speed, real-time communication for precise operational control.

Product Parameters & Specifications:

- Model Name: GE IS200TSVOH1BCC

- Module Type: Turbine Supervisory I/O (TSI/O) Module

- Compatibility: Designed for GE Mark VIe Distributed Control System (DCS) and PLC systems

- Functionality:

- Acts as an interface between the turbine’s I/O systems and the DCS/PLC for control and monitoring.

- Monitors turbine signals and sends commands to control devices like turbines, governors, and valves.

- Communication Protocol:

- Utilizes Ethernet-based communication protocols (specific protocol depend on configuration within the Mark VIe system).

- Turbine Control Communication Protocols (may include proprietary GE protocols for turbine applications).

- Inputs/Outputs:

- Digital Inputs: Typically used for sensors and switches (e.g., turbine position feedback, temperature, pressure sensors).

- Digital Outputs: Used for controlling turbine-related actuators (e.g., valves, trip relays).

- Analog Inputs: Supports analog signals like turbine speed, power output, and other continuous variables.

- Analog Outputs: Used for controlling processes such as turbine valve positions, temperature regulation, etc.

- Power Supply:

- 24 VDC (or similar, depending on the specific configuration and integration with the system).

- Network Interface:

- Ethernet-based communication with the DCS/PLC system via RJ45 connections.

- Fast and reliable transmission of real-time control and monitoring signals over the industrial Ethernet network.

- Status Indicators:

- LED indicators for power, input/output signal activity, and network status.

- Diagnostic LEDs for troubleshooting and maintaining system integrity.

- Mounting Type: Rack-mounted, compatible with Mark VIe racks.

- Dimensions: Approx. 12.0 cm (L) x 8.0 cm (W) x 4.5 cm (H) (may vary slightly based on configuration).

- Weight: Approx. 0.5 kg.

- Material: Durable industrial-grade housing for high reliability in demanding environments.

- Operating Temperature Range: 0°C to 60°C

- Storage Temperature Range: -20°C to 70°C

- Humidity Range: 5% to 95% non-condensing

- Protection Class: IP20 (suitable for indoor use)

- Field Wiring: Screw terminal blocks for easy field wiring.

- Certifications: Typically includes UL, CE, and other relevant industrial certifications.

Additional Features:

- Real-Time Diagnostics and Monitoring:

- Continuous health monitoring and diagnostics of input/output signals, allowing early detection of potential issues.

- Network diagnostics to ensure smooth communication between the module and the DCS/PLC.

- Secure Communication:

- The module supports secure data transfer, protecting critical turbine operation data from unauthorized access.

- Advanced Time Synchronization:

- Supports Network Time Protocol (NTP) for synchronizing all system clocks across distributed turbine control systems.

- Integration with GE Turbine Control Systems:

- Optimized for use with GE Turbine Control Systems in power plants, oil & gas refineries, and other critical infrastructure applications.

- Network Redundancy:

- Supports network redundancy protocols (if available in system) for failover in case of communication link failure.

- Customization and Flexibility:

- Can be configured with different I/O ranges, protocol setups, and diagnostic parameters to meet specific needs of turbine control applications.

Applications:

-

Power Generation Plants:

- Integral to turbine control and monitoring in thermal, nuclear, and hydroelectric power plants.

- Allows precise control of turbine governors, valves, and other vital turbine functions to ensure maximum efficiency and reliability.

-

Oil & Gas Industry:

- Used in gas turbine-driven compressors, pumps, and other critical machinery for power generation, oil extraction, and gas transportation systems.

-

Water Treatment and Desalination:

- Controls turbine-driven pumps and other critical systems in large-scale water treatment or desalination plants.

-

Heavy Manufacturing:

- Controls turbine-driven generators or turbines used in industrial machinery that require fine-tuned regulation.

Advantages:

- High Reliability: Built to operate in harsh industrial environments, ensuring that turbine control systems are continuously running with minimal downtime.

- Ease of Integration: Works seamlessly with GE Mark VIe DCS and PLC systems, offering easy integration into existing turbine control setups.

- Scalability: Can be easily expanded by adding additional I/O modules to meet the growing needs of turbine control systems.

- Security: Enhanced network security features protect against unauthorized access to critical turbine control signals.

- Advanced Diagnostics: The module’s diagnostic capabilities allow for easy troubleshooting and proactive maintenance, reducing system downtime.

- Precise Control: Provides high-precision control for turbine operations, ensuring optimal performance across a range of turbine systems.

The GE IS200TSVOH1BCC Turbine Supervisory I/O module is a vital component for turbine control in distributed control systems, offering high reliability, real-time diagnostics, and secure communication. It is perfect for high-performance environments such as power generation, oil and gas, and critical industrial applications, where precise control over turbine operations is crucial.

5441-635 PLC

5437-860 PLC

5453-754 PLC

5460-796 PLC

5460-836 plc

5460-837 DCS

5441-671

5460-838 PLC

5441-673 PLC

5460-839

5460-840 PLC

5460-841 IO

5460-842 DCS

5460-843

5460-844 PLC

5461-002 PLC

5441-689 PLC

5461-062 PLC

5461-082

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922