الوصف

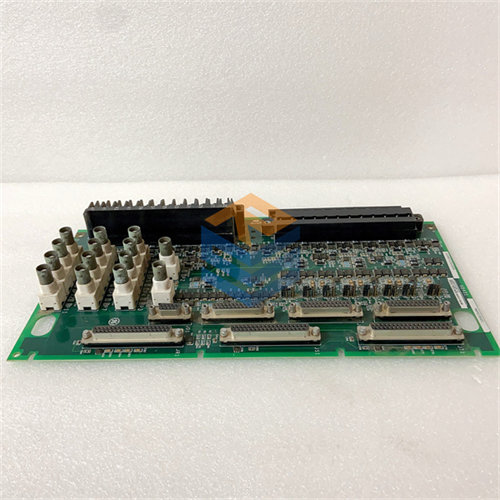

The GE IS200TVIBH2BBB is part of the GE (General Electric) Mark VIe series, a widely used system for controlling and monitoring gas turbines, steam turbines, and other industrial applications. The IS200TVIBH2BBB specifically functions as a vibration monitor and protection module, which is crucial for detecting and preventing damage to machinery by continuously monitoring vibration levels.

Here’s a detailed breakdown of the GE IS200TVIBH2BBB module:

GE IS200TVIBH2BBB – Vibration Monitor Module

General Overview:

The IS200TVIBH2BBB is a vibration monitoring module within the GE Mark VIe Control System, designed for applications that require real-time monitoring of vibration and shaft displacement in rotating machinery like gas turbines, steam turbines, and compressors. It helps protect equipment from mechanical damage by ensuring vibration levels stay within safe operating ranges.

Key Features and Functions:

-

Vibration Monitoring:

- The module is primarily used for vibration monitoring in rotating machinery, ensuring that the equipment is running smoothly and within safe limits.

- It monitors vibration levels through sensors that detect displacement, acceleration, and velocity.

-

Protection and Shutdown:

- It includes alarm and shutdown functionality. When vibration levels exceed predefined thresholds, the module can trigger alarm signals or initiate shutdown commands to protect the equipment from damage.

-

Signal Processing:

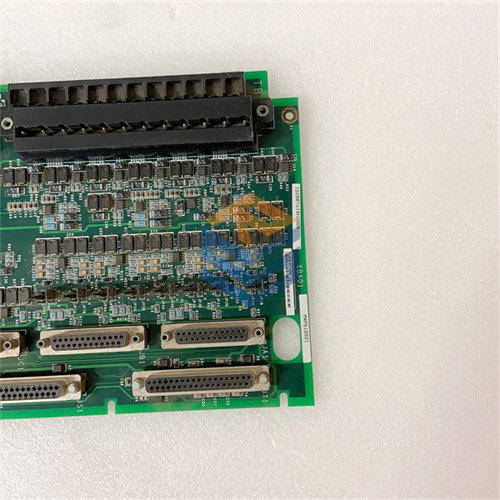

- The module processes input signals from vibration sensors (such as accelerometers or proximity probes) and converts them into useful data for operators or other control systems.

-

Integrated with Mark VIe System:

- The IS200TVIBH2BBB is integrated into the Mark VIe system, providing seamless communication with other modules, controllers, and the central system. This integration ensures real-time monitoring and quick response to potential issues.

-

Compatibility:

- Compatible with a range of vibration sensors, including proximity probes, accelerometers, and other displacement measurement devices.

- Provides digital and analog outputs for easy integration with other systems and controllers.

Specifications:

-

Input:

- Proximity Probes: Used for measuring shaft displacement.

- Accelerometers: For measuring vibration acceleration.

- Velocity Transducers: To monitor the velocity of vibration.

-

Output:

- Analog Output: Continuous output representing the vibration levels.

- Digital Output: Alarm or shutdown signals when vibration exceeds the threshold.

-

Power Supply:

- Typically operates on 24V DC or similar power sources, depending on the configuration.

-

Communication:

- Communicates with the Mark VIe control system, allowing data to be shared across the system for analysis and monitoring.

-

Environmental Resistance:

- Shock and vibration resistance: The module is built to withstand harsh operating conditions commonly found in industrial applications.

- Temperature Range: Typically operates within -40°C to +70°C.

-

Modular Design:

- The IS200TVIBH2BBB fits into the Mark VIe’s modular design, making it easy to integrate and expand the system.

Applications:

- Gas Turbines: Used to monitor vibration levels in gas turbines during operation, ensuring that they do not exceed safe thresholds.

- Steam Turbines: Protects steam turbines from excessive vibration that could lead to mechanical failure.

- Compressors: Monitors compressors in critical industrial processes, such as oil and gas extraction, power generation, and petrochemical production.

- Industrial Machinery: Used in other types of machinery where vibration monitoring is critical for preventing damage and ensuring smooth operation.

Certification and Compliance:

- The IS200TVIBH2BBB module typically complies with various industry standards for safety, quality, and reliability, including CE and UL certifications, which indicate compliance with European safety and U.S. safety standards.

Summary:

The GE IS200TVIBH2BBB is an advanced vibration monitoring and protection module for critical industrial machinery within the Mark VIe control system. It plays a crucial role in preventing damage to machinery by continuously monitoring vibration levels and triggering alarms or shutdowns when dangerous conditions arise.

Let me know if you need more information or if there’s anything specific you’d like to know about the IS200TVIBH2BBB!

ABB D0815 PLCI/O

ABB DO814 3BUR001455R1 PLC

3BUR001455R1 PLC

D0814 PLC

3BSE008510R1 ABB

ABB D0810 PLCDCS

DI831 3BSE013212R1 ABB PLC

3BSE013212R1 ABB PLC

DI831 DCS

DI830 3BSE013210R1 PLC

3BSE013210R1 ABB PLC

DI830 ABB PLC

DI821 3BSE008550R1 PLC

ABB 3BSE008550R1 PLC

DI821 ABB

DI820 3BSE008512R1 ABB PLC

3BSE008512R1 ABB PLC

ABB DI820 PLC

DI814 3BUR001454R1 ABB PLC

3BUR001454R1 DCS

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922