الوصف

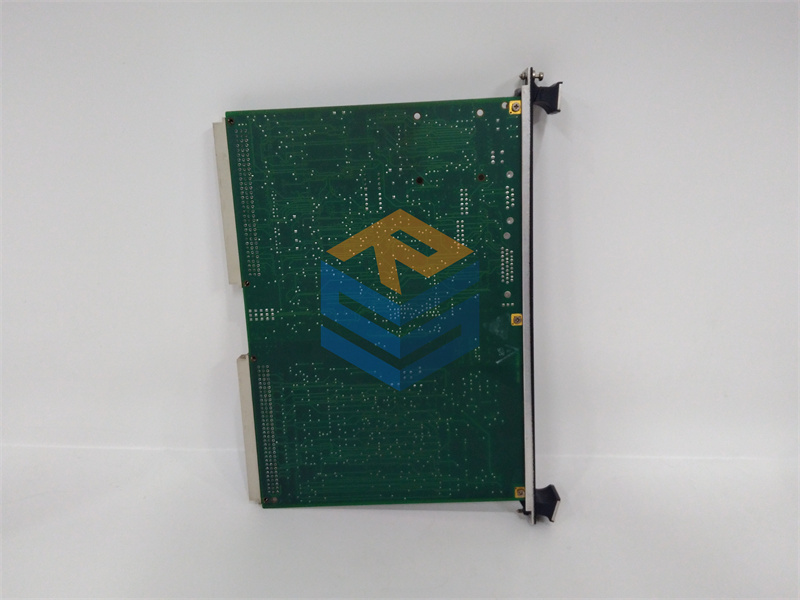

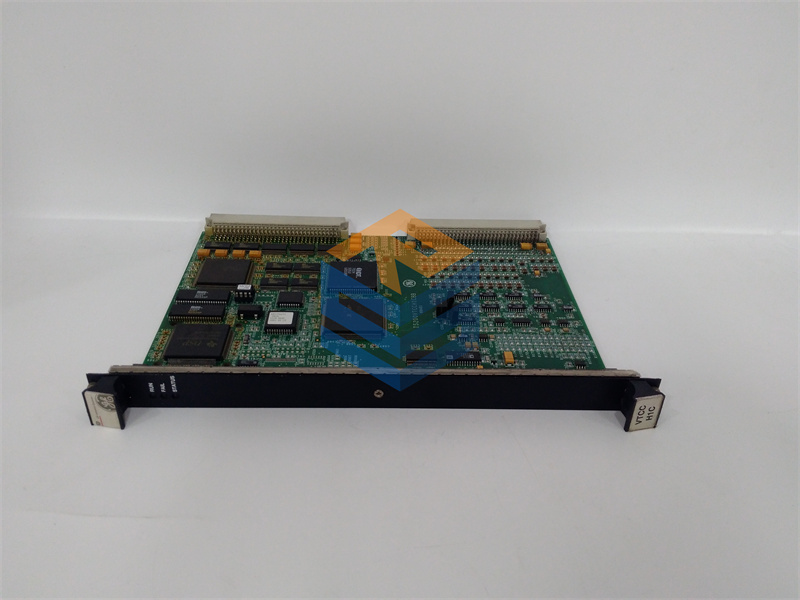

Product Name: GE IS200VTCCH1CBB PLC Module

Product Description:

The GE IS200VTCCH1CBB is a Versatile Terminal Control Module used in GE’s Mark VIe control systems, commonly employed in large-scale industrial automation applications, particularly in power generation, oil & gas, and chemical process industries. This module is part of the GE Speedtronic series and functions as a critical component in controlling complex machinery, offering precise terminal control, data communication, and system diagnostics. It provides highly reliable real-time processing capabilities and supports integration with other GE modules, facilitating seamless operations across large control systems.

The IS200VTCCH1CBB serves as an interface between the field devices (sensors, actuators, and other components) and the central control system, enabling the collection of data and the issuance of control commands. Its rugged design and ease of integration make it suitable for use in mission-critical applications where uptime and performance are paramount.

Product Parameters:

- Manufacturer: General Electric (GE)

- Model: IS200VTCCH1CBB

- Type: Versatile Terminal Control Module

- Application: Industrial automation, power generation, process control, and oil & gas industries

- Function: Interfaces with field devices for data collection and control signal transmission

- Communication Protocols: GE-specific communication protocols, Modbus, Ethernet/IP, and other industrial protocols (depending on configuration)

- Compatibility: Compatible with GE Mark VIe and other Speedtronic control systems

Specifications:

-

Processing Power:

- Processor: Advanced processing unit capable of high-speed control and data acquisition

- Clock Speed: Optimized for real-time control with rapid response times

- Control Loops: Supports multiple high-frequency control loops for fast-acting processes

-

Memory:

- RAM: Typically includes a sufficient amount of memory to handle the I/O and control processing tasks associated with complex control systems

- Non-Volatile Storage: Flash memory for storing configuration settings, firmware, and diagnostic logs

- Backup Memory: Battery-backed memory to maintain critical system data during power outages

-

Input/Output (I/O):

- I/O Types: Supports digital, analog, and high-speed inputs/outputs for controlling field devices like actuators, sensors, and control valves

- Expandable I/O: Can integrate additional I/O modules for larger or more complex systems

- Signal Conditioning: Provides analog signal conditioning to interface with field devices requiring voltage/current outputs

-

Communication:

- Ethernet Ports: Gigabit Ethernet ports for high-speed communication with the central control system and other devices

- Fieldbus Protocols: Supports various industrial communication standards, including GE’s proprietary communication protocols, Modbus TCP, and Ethernet/IP

- Serial Communication: RS-232/RS-485 interfaces available for legacy devices or slower communication needs

- Diagnostic Ports: Includes dedicated ports for system diagnostics and monitoring via software tools

-

Power Requirements:

- Operating Voltage: Typically operates with a 24V DC power supply (may vary depending on system configuration)

- Power Consumption: Approximately 20W to 50W (depends on configuration and number of connected devices)

- Power Redundancy: Some configurations allow for dual power supplies for increased reliability

-

Environmental Specifications:

- Operating Temperature Range: Typically -10°C to 60°C (14°F to 140°F), though some versions may offer wider temperature ranges for harsh environments

- Storage Temperature Range: -20°C to 85°C (-4°F to 185°F)

- Relative Humidity: 5% to 95%, non-condensing

- Vibration and Shock Resistance: Designed to meet industrial-grade standards, offering shock and vibration tolerance for use in rough environments

-

Safety and Certifications:

- Compliance: CE, UL, RoHS, and other relevant industrial certifications for quality, safety, and electromagnetic compatibility

- EMC Compatibility: Designed to meet industrial electromagnetic compatibility standards to minimize interference

-

Software and Programming:

- Programming Interface: Supports GE’s Proficy and Mark VIe software environments for configuration and control logic programming

- Programming Languages: Compatible with standard control logic, including Ladder Logic, Structured Text, and Function Block Diagrams in accordance with IEC 61131-3

- Remote Access: Offers secure remote diagnostics and configuration capabilities via networked connections

-

Mounting and Form Factor:

- Mounting Options: Designed for rack-mount or DIN rail installation, depending on the specific configuration

- Dimensions: Approximately 100mm x 200mm x 40mm (can vary depending on specific configuration)

-

Expansion and Scalability:

- Modular Expansion: The IS200VTCCH1CBB can be used as part of a larger system with the ability to integrate additional I/O, control modules, and communication interfaces

- Remote I/O Integration: Can connect with remote I/O systems to control devices located in distant areas of a facility or process plant

Key Features:

- Real-Time Data Processing: Offers rapid processing of data from field devices, enabling precise control over complex systems.

- Versatile I/O Capabilities: Supports a broad range of input and output types, allowing for flexible system design and scalability.

- High-Speed Communication: Multiple communication options including high-speed Ethernet and fieldbus protocols for seamless integration with other control and automation systems.

- Reliability and Redundancy: Built for high reliability in mission-critical applications, with options for power supply redundancy and fault tolerance.

- Advanced Diagnostics: Integrated diagnostic tools for troubleshooting, remote monitoring, and system health checks.

- Flexible Programming: Supports multiple programming standards, allowing for ease of integration into diverse industrial environments.

Applications:

- Power Generation: Used in power plant automation systems for turbine control, generator control, and other critical processes.

- Oil & Gas: Plays a role in controlling valves, pumps, and other equipment in oil and gas processing plants.

- Process Control: Widely employed in chemical processing plants, pharmaceuticals, food processing, and other industries where precise control of variables like temperature, pressure, and flow is required.

- Industrial Automation: Common in applications where large, complex machinery needs to be automated and controlled with high precision.

Conclusion:

The GE IS200VTCCH1CBB PLC module is a versatile and robust control module ideal for high-performance industrial applications that require precise terminal control, reliable communication, and seamless integration with larger automation systems. Its modular and scalable design, along with support for multiple industrial communication protocols, makes it an excellent choice for power generation, process control, and other mission-critical environments where uptime and reliability are paramount.

HDPE SDR 13.5 Fiber Optic Conduit Pipe 30,000FT BLUE

HDPE SDR 13.5 Fiber Optic Conduit Pipe 30,000FT GREEN

McCormick F-CUB Tractor

CUTLER-HAMMER SPB100 CIRCUIT BREAKER

VG Gas Analysis System

5 ECONO LIFT TR20 TOTE BOX TILTERS

Brown & Sharpe Traverse Surface Grinder No1 S148826

Veet 3R Precision Radial Arm Drill

HDPE SDR 13.5 Fiber Optic Conduit Pipe 30,000 ft

TECHNIC TNR301 GOLD STRIKE BATH

2 CONAIR 18041202 MOLDING DEHUMIDIFYING DRYER 480V 3PH

Autojecter WDHS75-S 75 Ton Vertical Injection Molding

Hubbell Hipotronics 715-1/S Hi-Pot AC Dielectric Test

Harig Bridgeport 618 Surface Grinder

3 Robinaire 17500B Refigerant Recovery and Recycling S

Sumitomo Wire Harness Resistance Welder System

BRANSON 10 LASER APETURE HEAD

2 Cutler-Hammer SPB100 Switchboards

MOORFEED VIBRATORY BOWL FEEDER 62″

MOORFEED VIBRATORY BOWL FEEDER 50″

18 Sony XC-73CE Video Vision Camera CCD

Chatillon TCD500 Tension Meter

MARCH QUADREL TL2 LABELING SYSTEM TABLETOP

Tektronix TDS714L Oscilloscope Color 500MHz 4Ch 500MSa

Schneider Automation 140 CPS 114 10 TSX Quantum PLC

IDEX PULSA SERIES 7660 DIAPHRAGM METERING PUMP

LEAR SIEGLER DYNATRON 1100M OPACITY MONITORING SYSTEM

Komax Alpha 411 Automatic Crimping Machine

Friedrich Deckel 2250 Pantograph

8 Va-Tran C02 Steam Cleaner MPS-1

2 Chuo 61 kVa S1-6-204 Resistive Spot Welders

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922