الوصف

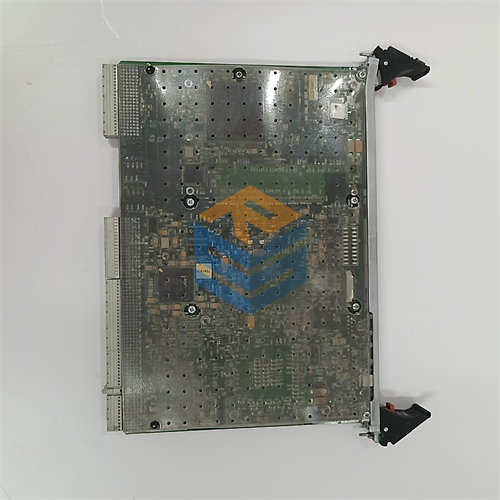

GE IS215UCCCM04AB DCS/PLC Module

Product Name:

GE IS215UCCCM04AB DCS/PLC Module

Product Description:

The GE IS215UCCCM04AB is a Distributed Control System (DCS) / Programmable Logic Controller (PLC) module from General Electric (GE), designed for industrial automation and control applications. It is part of the Mark VIe series, a scalable and reliable solution for controlling complex industrial processes, commonly used in power plants, oil & gas, chemical plants, and other industrial settings.

The IS215UCCCM04AB module functions as a communication interface within the Mark VIe control system, facilitating the integration of various field devices and other control modules. This module ensures data exchange between control systems, field instruments, and other industrial equipment via established communication protocols. It is built to provide high availability, safety, and operational efficiency, with flexible configuration and modularity to suit diverse operational needs.

GE’s Mark VIe system is known for its real-time control, diagnostics, and secure communication, offering industry-leading redundancy and failover capabilities, which are critical in mission-critical operations where downtime is not an option.

Key Features:

-

Real-Time Control and Communication:

- Provides real-time data exchange between field devices, control systems, and operators. Critical for processes where immediate action and feedback are essential.

-

Modular and Scalable Design:

- Its modular design allows users to tailor their system to specific needs, ensuring it can grow or scale down as required.

-

High Availability and Redundancy:

- Features redundant power supplies and communication paths, ensuring the system remains operational even in case of hardware failures or communication loss.

-

Flexible Connectivity:

- Supports multiple communication protocols such as Ethernet, Modbus, Profibus, and others, ensuring integration with diverse industrial devices and systems.

-

Safety and Reliability:

- Designed to meet safety standards such as SIL (Safety Integrity Level) requirements, suitable for use in safety-critical applications.

-

Diagnostic and Monitoring Tools:

- Includes advanced diagnostics for real-time health checks, enabling predictive maintenance and quick fault detection, minimizing downtime.

-

Ease of Configuration and Programming:

- Supports user-friendly programming languages and software tools for easy configuration, troubleshooting, and system management.

-

Compact and Efficient:

- Its compact size makes it ideal for applications with limited space, while still offering high processing power.

Product Parameters and Specifications:

General Specifications:

- Product Name: IS215UCCCM04AB

- Type: DCS/PLC Communication Module

- Manufacturer: General Electric (GE)

- Series: Mark VIe

- Function: Communication Interface for DCS/PLC systems

Electrical Specifications:

-

Input Voltage:

- Typically operates on 24V DC with a standard operational range of 20V DC to 30V DC.

-

Power Consumption:

- Power consumption is typically 10W to 30W, depending on the load and configuration.

-

Operating Temperature Range:

- 0°C to +60°C (32°F to 140°F), suitable for industrial environments.

-

Storage Temperature Range:

- -40°C to +85°C (-40°F to 185°F).

-

Relative Humidity:

- Designed to operate in 5% to 95% non-condensing humidity environments.

I/O Configuration:

-

Digital I/O:

- Features digital inputs and outputs for discrete control of switches, alarms, relays, etc.

-

Analog I/O:

- Supports analog inputs (4-20mA, 0-10V) and outputs to control variables such as pressure, temperature, or flow.

-

Communication Ports:

- Equipped with Ethernet ports (for fast, reliable communication), serial ports (RS232/RS485), and other fieldbus options for connecting a wide variety of industrial devices.

Communication and Networking:

-

Supported Protocols:

- Ethernet/IP, Modbus RTU/TCP, Profibus DP, and others, ensuring flexibility in integrating with different types of industrial devices and systems.

-

Redundant Communications:

- Provides redundant Ethernet and fieldbus communication paths, ensuring continuous data exchange even in the event of a failure.

-

Communication Rate:

- Supports high-speed communication for real-time control and monitoring, with Ethernet data rates up to 100 Mbps.

Safety and Compliance:

-

Safety Certifications:

- Meets SIL requirements for safety-critical applications, offering safety and reliability in hazardous environments.

-

EMC Compliance:

- Complies with Electromagnetic Compatibility (EMC) standards to minimize interference from external electrical sources and ensure reliable communication.

-

Hazardous Area Certification:

- Suitable for use in hazardous environments (depending on configuration), with certifications like ATEX and IECEx for explosion-proof operation.

Software and Programming:

-

Programming Languages:

- Supports programming in standard IEC 61131-3 languages such as Ladder Logic, Structured Text, Function Block Diagram (FBD), and Sequential Function Chart (SFC).

-

Configuration Tools:

- Works with GE’s configuration and programming tools such as Proficy Machine Edition for easy setup, programming, and troubleshooting.

-

System Integration:

- Easily integrates into larger DCS/PLC systems using standard communication protocols, facilitating seamless control and monitoring across various devices and systems.

Maintenance and Diagnostics:

-

Real-Time Diagnostics:

- Built-in diagnostic features for continuous health monitoring of both the hardware and the connected devices, identifying faults and providing error logs for troubleshooting.

-

Predictive Maintenance:

- Supports predictive maintenance strategies by continuously analyzing operational data and providing early warnings of potential failures.

-

Event Logging:

- Event logging for capturing system events, changes, alarms, and other critical data to help operators make informed decisions and optimize performance.

Applications:

-

Power Generation:

- Ideal for use in power plants, providing control and monitoring for turbines, generators, and auxiliary equipment.

-

Oil and Gas:

- Used in drilling rigs, refineries, and pipeline control, ensuring safe and efficient operation in hazardous environments.

-

Chemical Processing:

- Used in chemical reactors, distillation columns, and storage tanks, offering precise control of critical parameters like pressure, temperature, and flow.

-

Water Treatment:

- Controls pumps, valves, and treatment chemicals in municipal water treatment plants, ensuring consistent water quality and supply.

-

Manufacturing:

- Used in assembly lines, robotic arms, and conveyor systems, automating processes to enhance efficiency and reduce human intervention.

-

Mining and Metals:

- Implements control strategies in mining operations, smelting, and metal refinement, ensuring reliable and efficient plant performance.

Conclusion:

The GE IS215UCCCM04AB DCS/PLC Module is a robust, flexible, and high-performance solution for industrial automation and control applications. Its redundancy, real-time communication, and modular design make it suitable for mission-critical environments such as power generation, oil & gas, chemical processing, and manufacturing. Designed with advanced diagnostics, safety compliance, and scalability, it ensures smooth, reliable, and safe operation across a wide variety of industries. This module’s ability to integrate with diverse industrial devices and systems, coupled with its strong communication protocols, makes it a valuable asset in optimizing control systems and improving operational efficiency.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922