الوصف

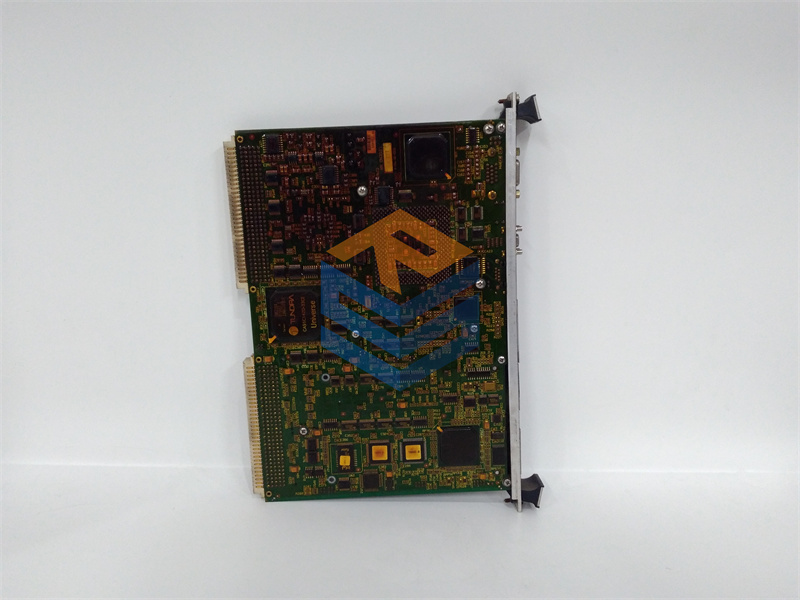

GE IS215UCVEH2AE DCS PLC Module

Product Name:

GE IS215UCVEH2AE

Product Description:

The GE IS215UCVEH2AE is a Communication Interface module designed for use in GE’s Mark VIe Distributed Control System (DCS). This specific module is part of the Mark VIe platform and is responsible for facilitating high-performance communication between various control and I/O modules within a distributed automation system. The IS215UCVEH2AE module enables data exchange between the DCS network, allowing real-time control and monitoring of complex industrial processes.

This module is crucial in process control applications that require seamless communication, fast data transfer, and robust system integration. As part of the GE Mark VIe system, it enhances system flexibility, scalability, and overall performance.

Typically used in industries such as power generation, oil and gas, chemical processing, and industrial automation, the IS215UCVEH2AE ensures continuous and reliable communication within the control network, making it an essential component in process control systems.

Product Parameters & Specifications:

Model:

- GE IS215UCVEH2AE

Module Type:

- Communication Interface Module (CIM)

- Part of Mark VIe DCS.

Communication Protocols Supported:

- Ethernet for high-speed communication within the DCS network.

- Modbus TCP/IP for communication with third-party devices.

- Ethernet/IP for integration into broader industrial networks.

- Profinet support for integration with field devices.

Input/Output Types:

- Ethernet Ports: Typically includes two Ethernet ports for network redundancy (optional in some configurations).

- I/O Interfaces: Provides communication with field I/O modules and other parts of the DCS system.

Processing Power:

- Designed for fast processing of real-time data.

- Handles data transfer, system diagnostics, and error correction.

- Ensures rapid communication across multiple control stations.

Power Supply:

- Typically operates on 24 V DC (for specific power configurations, consult the system manual).

Redundancy Features:

- Redundant Communication Paths for system reliability and fault tolerance.

- Designed to prevent single points of failure in critical communication paths.

Operating Temperature Range:

- Operating: 0°C to 60°C (32°F to 140°F).

- Storage: -40°C to 85°C (-40°F to 185°F).

Environmental Protection:

- IP20 rating (suitable for indoor use in controlled environments).

- Requires external protective measures if exposed to harsh environmental conditions.

System Compatibility:

- Compatible with the GE Mark VIe DCS system.

- Integrates seamlessly with GE Mark VIe modules such as I/O modules, processor modules, and HMI (Human Machine Interface) systems.

Communication Ports:

- Ethernet Ports: Two ports for redundancy.

- Serial Communication: Optional serial ports for legacy systems or additional peripheral devices.

Network Support:

- Support for TCP/IP, UDP, Modbus, Profinet, and Ethernet/IP for communication with various system components.

- Offers high-speed data transmission to support demanding applications.

Memory & Storage:

- Equipped with flash memory for storing system configurations and firmware.

- Non-volatile memory ensures data retention even in the event of power loss.

Dimensions:

- Approximate size: 7.75″ (W) x 9.5″ (H) x 2.5″ (D) (may vary depending on specific configuration).

Weight:

- Typically around 1.5 kg (subject to variations based on configuration).

Safety Standards:

- Compliant with UL, CE, CSA, and other international safety standards.

- Designed for functional safety and reliability in industrial environments.

Additional Features:

- Diagnostic Capabilities: In-built diagnostics for monitoring communication status, identifying potential issues, and troubleshooting.

- Status Indicators: LED indicators to show operational status, fault conditions, and communication activity.

- Hot Swap Capability: Can be replaced without the need to shut down the system, improving system uptime.

- Scalability: Easy integration with other Mark VIe modules for expanded system capabilities.

Advantages & Features:

-

Reliable Communication:

The IS215UCVEH2AE ensures high-speed and reliable communication between distributed modules and field devices, reducing downtime and improving system performance. -

Redundant Paths for Reliability:

The module supports redundant communication paths, ensuring fault tolerance and high availability in critical systems where communication failure cannot be tolerated. -

Seamless Integration:

It integrates easily into the GE Mark VIe system, allowing for easy configuration and expansion of control systems. -

Enhanced Diagnostics:

The module’s built-in diagnostic features help detect faults quickly, improving system maintenance and reducing troubleshooting time. -

Scalability:

The system is highly scalable, supporting additional modules as system demands grow, making it suitable for large-scale industrial applications. -

Flexibility in Communication Protocols:

The IS215UCVEH2AE supports a wide range of communication protocols, making it highly flexible and compatible with both GE and third-party equipment. -

Rugged Industrial Design:

Designed to withstand the demanding conditions of industrial environments, ensuring durability and long-term performance.

Applications & Use Cases:

The GE IS215UCVEH2AE module is ideally suited for the following applications:

- Power Generation: Used in power plants to facilitate communication between turbine control systems, generator monitoring, and electrical distribution systems.

- Oil & Gas: Used in upstream and downstream operations, including drilling rigs, pipeline control, and refinery automation.

- Chemical Processing: Manages communication between sensors, actuators, and controllers in chemical production processes.

- Water Treatment: Facilitates the exchange of data between water treatment plants, ensuring consistent quality control and real-time monitoring.

- Industrial Automation: Used in factory automation systems for managing production lines, machinery, and robotics.

Comparison with Other Systems:

When compared to other DCS communication modules such as those from Emerson DeltaV or Honeywell Experion, the GE IS215UCVEH2AE stands out for its robust redundant communication features, diagnostic capabilities, and integration flexibility. The Mark VIe system, in particular, excels in environments that require high reliability, fast processing, and seamless data exchange across a large network of control systems and field devices.

Selection Recommendations:

-

Communication Reliability:

If your application requires high reliability and continuous communication between distributed control and field devices, the IS215UCVEH2AE is ideal due to its fault tolerance and redundant network paths. -

Real-time Control Systems:

Choose the IS215UCVEH2AE if you are working in industries like power generation, oil, gas, or chemical processing, where real-time control and monitoring are critical. -

Scalability Needs:

If you anticipate the need to scale your system over time, this module’s modular design and networking flexibility make it suitable for future expansions. -

High Availability:

If system uptime is crucial for your application, the redundant communication paths and hot swap capability of this module ensure that communication remains uninterrupted.

Let me know if you need further details or clarification!

Axcelis 697221 PLC DCS

Axecelis 697221 PLC DCS

Axcelis 10661 PLC DCS

Hermos Brooks GW-S1HS-KOL2 PLC DCS

Axcelis 668111 PLC DCS

Axcelis 552771 PLC DCS

Axcelis 560821 PLC DCS

Axcelis 557841 PLC DCS

Axcelis 531061 PLC DCS

Axcelis 652961 PLC DCS

Intronics 2B52A PLC DCS

Axcelis 462091 PLC DCS

ASML 4022.471.5691 PLC DCS

ASML 4022.471.7196 PLC DCS

ASML 4022.436.6475 PLC DCS

PULS 4022 47602011 PLC DCS

Kniel 4022 436 43072 PLC DCS

Hartmann & Braun P10830-0-652300 PLC DCS

FANAL ESA3000-D-44 PLC DCS

BALDOR SMCC 602090-450 PLC DCS

LiftEquip MFC20-12 PLC DCS

Yokogawa SC41-SP43 PLC DCS

Raychem VIA-DU-20 PLC DCS

HWH Harms+Wende MPS9173 PLC DCS

Datalux LMV10R3 PLC DCS

BALDOR SBTS10-200-2 PLC DCS

BALDOR S-BTS10 PLC DCS

HWH Harms+Wende MPS9173 PLC DCS

BALDOR ASR SBTS10-200-2 PLC DCS

WIPOTEC IPC SWA2-133 PLC DCS

Bently Nevada PW 140734-01 PLC DCS

Hopf System 6000 DCF PLC DCS

HWH Harms+Wende MPS9173c PLC DCS

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922