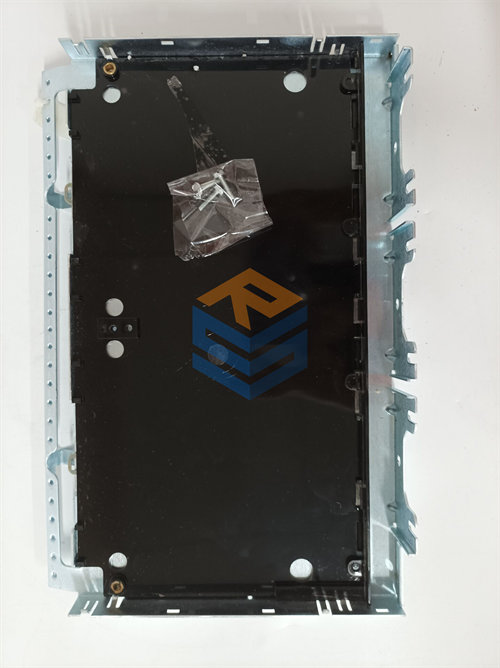

الوصف

Product Name:

GE+IS230TDBTH6A DCS PLC Module

Product Description:

The GE+IS230TDBTH6A is a high-performance Distributed Control System (DCS) module developed by General Electric (GE) for use in industrial automation systems. It is part of the Mark VIe system and specifically designed for advanced control, monitoring, and protection of industrial processes, particularly in high-demand industries such as power generation, oil and gas, chemical processing, and other mission-critical applications.

The IS230TDBTH6A module acts as a digital input/output interface, enabling seamless integration with various system components. It is known for its high reliability, flexibility, and real-time control capabilities, making it an ideal choice for controlling and monitoring complex industrial operations. The module is engineered to ensure high uptime and safety by offering redundant features, real-time diagnostics, and fault-tolerant design.

Product Parameters & Specifications:

General Specifications:

- Model: GE+IS230TDBTH6A

- Type: DCS (Distributed Control System) Digital Input/Output Module

- Manufacturer: General Electric (GE) Automation and Controls

- Series: Part of the Mark VIe system

- Primary Use: Digital input/output interfacing, control, and monitoring for industrial automation systems

- Functionality: Provides digital I/O functionality for DCS systems in industries such as power generation, oil & gas, chemical, and petrochemical.

Key Features:

- Digital I/O Capabilities: The module offers both digital inputs and digital outputs, making it versatile for various control and monitoring applications.

- High Reliability: Designed with redundant power supplies, communication paths, and internal diagnostics to ensure reliability and uptime in critical industrial environments.

- Fault-Tolerant Design: Includes fault detection and automated diagnostics to mitigate potential failures and enhance system robustness.

- Real-Time Data Processing: Capable of fast data handling and processing for accurate, time-sensitive decision-making in industrial processes.

- Communication Compatibility: The module integrates seamlessly with Mark VIe systems and supports a variety of communication protocols for system integration.

- Modular Design: The IS230TDBTH6A is part of a modular control system, allowing for flexible expansion and customization based on specific process needs.

Electrical Specifications:

-

Power Supply:

- Nominal Supply Voltage: Typically operates on 24V DC.

- Redundant Power: Built-in power supply redundancy to maintain continuous operation in case of power failures.

-

Power Consumption:

- Optimized for low power consumption, typically consuming less than 10 watts depending on the configuration and load.

-

Input Voltage Range:

- Designed to operate within the 24V DC range to accommodate typical industrial power conditions.

-

Current Draw:

- Typical Current Draw: Approximately 0.5 to 1.0 A at nominal voltage, depending on the operational load and I/O configuration.

-

Communication Protocols:

- Ethernet: High-speed data transfer for seamless integration with industrial network systems.

- Modbus: A widely-used protocol for data transfer and communication in industrial environments.

- RS-485: Supports serial communication, allowing for long-distance communication across industrial networks.

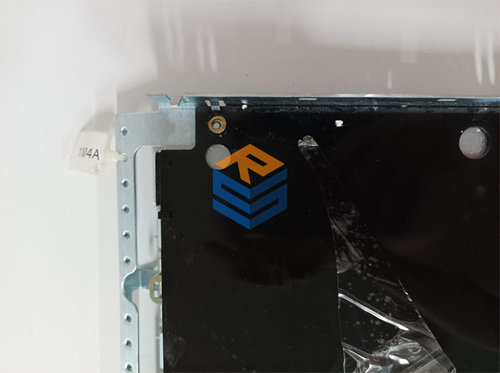

Mechanical Specifications:

-

Form Factor:

- Designed to fit into a rack-mounted system, typically a 19-inch standard control rack.

-

Dimensions:

- Height: 3U (roughly 130 mm)

- Depth: Around 200 mm (subject to specific configuration)

- Width: Typically 3-4 cm depending on the model.

-

Cooling:

- The module is designed for passive cooling but requires proper ventilation in a controlled environment to maintain an optimal operating temperature.

-

Weight:

- Approximately 1.5 to 2.0 kg depending on configuration.

-

Enclosure Protection:

- Typically, the module is housed in a IP20 rated enclosure, providing protection against accidental contact and limited dust ingress.

Environmental Specifications:

-

Operating Temperature:

- Typically rated for -20°C to +60°C for use in diverse industrial settings, including harsh environments.

-

Storage Temperature:

- The module can be stored safely in temperatures ranging from -40°C to +85°C.

-

Relative Humidity:

- The system is capable of operating in environments with 5% to 95% non-condensing relative humidity.

-

Vibration and Shock Resistance:

- Built to withstand typical industrial vibrations and shocks, adhering to industrial standards for ruggedness and reliability.

Functional Specifications:

-

I/O Capabilities:

- The IS230TDBTH6A provides both digital inputs and digital outputs. It typically includes:

- Digital Inputs: For sensing signals from industrial devices such as switches, sensors, and other control devices.

- Digital Outputs: For driving actuators, relays, and other industrial equipment.

- The IS230TDBTH6A provides both digital inputs and digital outputs. It typically includes:

-

Redundancy:

- Offers redundant processors and communication pathways to ensure uninterrupted system operation.

-

Diagnostics:

- Built-in diagnostic capabilities allow for real-time monitoring of system health, ensuring that any faults are quickly detected and addressed.

-

Control Logic:

- Supports complex control algorithms for industrial processes that require high precision and reliable performance.

-

Safety:

- Designed to ensure the safety of the controlled processes by providing features such as fail-safe operation, real-time monitoring, and advanced diagnostics.

-

Alarms and Event Logging:

- Capable of generating alarms and logging events to track system performance and assist in troubleshooting.

Software and Configuration:

-

Configuration Software:

- The module is configured using GE’s Mark VIe software suite, which includes tools like Proficy iFIX, Proficy CIMPLICITY, or other compatible software.

-

Diagnostics and Monitoring Tools:

- Real-time diagnostic and monitoring tools are available for continuous health checks, fault detection, and system status updates.

- Operators can access historical data logs for troubleshooting and performance review.

-

Programming:

- Programming and configuration are simplified with graphical interfaces and drag-and-drop programming methods that facilitate faster setup and modification.

Applications:

-

Power Generation:

- Ideal for use in power plants for controlling turbines, generators, and other critical components in a safe and reliable manner.

-

Oil & Gas:

- Used in drilling, pumping, and refining operations for precise process control and monitoring.

-

Chemical and Petrochemical:

- Suitable for controlling complex chemical processes, ensuring safety, and maintaining optimal production efficiency.

-

Manufacturing & Industrial Automation:

- Ideal for controlling production lines, assembly processes, and manufacturing systems that require high reliability.

-

Water Treatment:

- Used for controlling and monitoring water treatment processes, pump stations, and other utility-based automation systems.

Conclusion:

The GE+IS230TDBTH6A DCS PLC Module is a robust and highly reliable solution for digital input/output control in complex industrial environments. With its redundant features, fault-tolerant design, and real-time diagnostics, it ensures high uptime and safety for mission-critical processes in industries such as power generation, oil & gas, chemical processing, and manufacturing. The module’s flexibility,

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922