الوصف

Product Name:

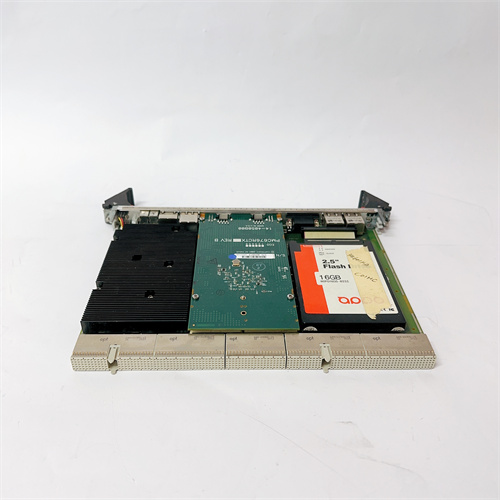

GE+PMC-0247RC-282000 350-93750247-282000F DCS/PLC Module

Product Description:

The GE+PMC-0247RC-282000 (also known by its part number 350-93750247-282000F) is a highly reliable Distributed Control System (DCS) / Programmable Logic Controller (PLC) module designed for use in demanding industrial environments. As part of the General Electric (GE) automation and control product family, this module provides advanced control and communication features that are ideal for complex process automation applications. It is commonly used in critical industrial sectors such as power generation, oil and gas, chemicals, and water treatment.

This module is built to handle a variety of input/output configurations, enabling it to interface with diverse field devices while ensuring seamless integration with other control systems. It is engineered to support high-performance real-time processing, providing precise control and monitoring for large-scale automation systems. With a focus on operational reliability, flexibility, and safety, the GE+PMC-0247RC-282000 ensures continuous, trouble-free system operation in demanding industrial settings.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) module

- Manufacturer: General Electric (GE)

- Model/Part Number: PMC-0247RC-282000 (350-93750247-282000F)

- Series: Part of GE’s DCS/PLC product line for industrial automation.

Input/Output Specifications:

- Digital Inputs: The module supports a range of digital inputs for discrete signals from sensors, switches, and other field devices.

- Digital Outputs: Offers digital outputs for controlling field devices such as actuators, relays, and motors.

- Analog Inputs: Includes analog input channels to measure continuous values such as temperature, pressure, and flow from analog sensors.

- Analog Outputs: Provides analog output channels to control continuous devices such as valve actuators, variable-speed drives, and other process control systems.

Communication Protocols:

- Modbus RTU/TCP: Supports Modbus RTU and Modbus TCP protocols, allowing for integration with a wide variety of field devices and control systems.

- Ethernet/IP: Ethernet/IP support provides high-speed and real-time communication in Ethernet-based networks for efficient data exchange and control.

- Profibus DP: The module is capable of integrating with Profibus DP-enabled devices for high-speed industrial networking.

- CANopen: Compatible with CANopen for communication with devices such as motors, drives, and sensors in automation systems.

Power Supply:

- Operating Voltage: Typically operates at 24 V DC or 48 V DC, depending on the configuration.

- Power Consumption: Energy-efficient, with power consumption depending on the configuration and field devices connected to the module.

Control and Performance:

- Real-Time Control: Provides real-time data processing and control, enabling fast responses to dynamic process changes.

- Processing Speed: Optimized for high-performance processing to handle complex and time-critical applications in industrial control systems.

- Response Time: Low latency, ensuring prompt system responses and precise control.

Environmental Specifications:

- Operating Temperature: Typically -20°C to 60°C (-4°F to 140°F), suitable for a wide range of industrial environments.

- Storage Temperature: -40°C to 85°C (-40°F to 185°F).

- Humidity: Operates in a 5% to 95% RH range, non-condensing.

- Vibration and Shock Resistance: Built to withstand typical industrial vibrations and shocks, complying with industrial standards.

Mounting and Integration:

- Mounting Type: Rack-mounted or panel-mounted configuration for easy integration with control systems.

- Slot Configuration: Typically part of a modular control system, with flexible slot configurations to scale the control system as needed.

Redundancy and Reliability:

- Redundant Power Supply: Available with redundant power supply configurations to ensure uninterrupted operation in case of power failure.

- Fail-Safe Operation: The module includes fail-safe mechanisms, ensuring system integrity in the event of faults.

Safety and Compliance:

- Safety Features: Designed for use in safety-critical applications, the module ensures system reliability in hazardous environments.

- Certifications: Compliance with CE, UL, and ATEX standards ensures safety and reliability in industrial environments.

Software and Programming:

- Control Software: Compatible with GE Proficy or similar GE automation software for system configuration, programming, and diagnostics.

- Programming Languages: Supports IEC 61131-3 programming standards, including Ladder Logic (LD), Structured Text (ST), Function Block Diagram (FBD), and others.

- Diagnostics and Maintenance: Software tools for system diagnostics, troubleshooting, and real-time monitoring of the control system’s status.

Diagnostics and Monitoring:

- Built-in Diagnostics: Equipped with LED indicators and diagnostic tools to monitor system performance and identify faults.

- Alarm Management: Capable of generating alarms and alerts to notify operators of critical events, ensuring quick responses to issues.

Key Features & Benefits:

-

Modular and Scalable:

- The GE+PMC-0247RC-282000 features a modular design, making it easy to scale and integrate into both small and large control systems.

-

High-Performance Real-Time Control:

- The module offers real-time control and processing, which is essential for industries with time-sensitive processes such as power generation and chemical manufacturing.

-

Flexible Communication Protocols:

- With support for a variety of industrial communication protocols like Modbus, Ethernet/IP, and Profibus, the module is highly versatile and integrates easily with existing automation networks.

-

Environmental Durability:

- Designed to withstand harsh industrial conditions, with a broad operating temperature range and vibration resistance, the module is suitable for deployment in demanding environments.

-

Safety-Critical Applications:

- The module is built to meet the rigorous requirements of safety-critical applications, such as those found in oil & gas, chemical processing, and power generation.

-

Redundancy for High Availability:

- With redundant power supplies and fail-safe operations, the module ensures continued system operation, even in the event of a fault.

-

Advanced Diagnostics and Monitoring:

- The built-in diagnostics tools provide real-time monitoring of system status, reducing downtime and facilitating proactive maintenance.

-

Compliant with Industrial Standards:

- Fully compliant with international safety and environmental standards (e.g., CE, UL, ATEX), ensuring that the module can be used safely in various global markets.

Applications & Use Cases:

- Power Generation: Control and monitoring of power plants, turbines, and electrical distribution systems.

- Oil & Gas: Automation and control of exploration and extraction processes, pipeline systems, and refinery operations.

- Chemical Processing: Control of chemical reactions, batch processes, and continuous manufacturing in chemical plants.

- Water Treatment: Automation of water treatment facilities, including monitoring and control of pumps, valves, and filtration systems.

- Manufacturing: Management of complex production lines, material handling, and assembly automation systems.

Conclusion & Recommendation:

The GE+PMC-0247RC-282000 (350-93750247-282000F) DCS/PLC Module is a robust and flexible automation solution designed to meet the demands of industrial control systems. With its high-performance control capabilities, wide range of communication protocols, and modular design, it is well-suited for applications across various industries, including oil & gas, chemical processing, power generation, and water treatment. The module’s focus on safety, diagnostics, and real-time performance ensures reliable operation in mission-critical environments, making it an ideal choice for industrial automation systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922