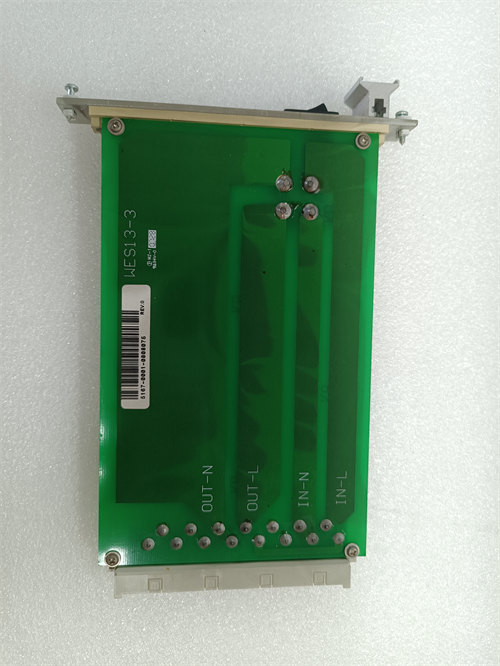

الوصف

Product Name:

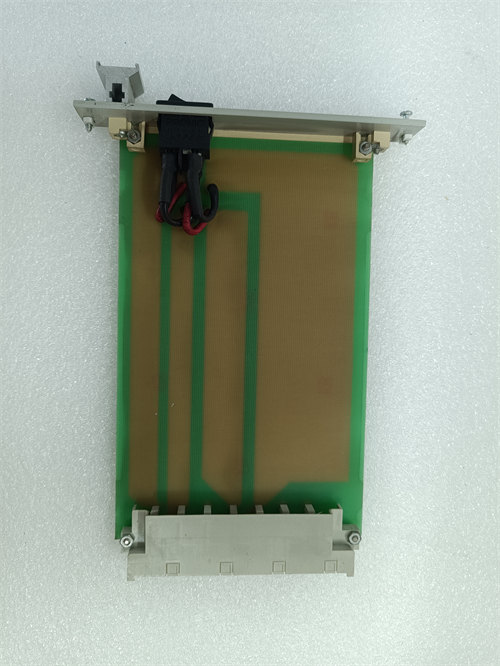

GE+WES13-3 5167-0001-0210 DCS PLC Module

Product Description:

The GE+WES13-3 5167-0001-0210 is a Distributed Control System (DCS) Programmable Logic Controller (PLC) module designed for use in advanced industrial control applications. Manufactured by General Electric (GE), this module is part of GE’s industrial automation systems, providing a high level of control and monitoring for industrial processes. It is typically used in industries such as oil and gas, power generation, chemical processing, and water treatment, where precision, reliability, and integration with complex control systems are essential.

The WES13-3 series is known for its robust performance and flexibility, offering multiple input and output configurations, along with support for various communication protocols. The 5167-0001-0210 module is tailored for use in GE DCS systems and is designed to seamlessly integrate with other components of the GE automation ecosystem, providing real-time data processing, diagnostics, and control.

Product Parameters:

- Model Number: GE+WES13-3 5167-0001-0210

- Type: DCS PLC Module

- Manufacturer: General Electric (GE)

- System Compatibility: GE DCS Systems

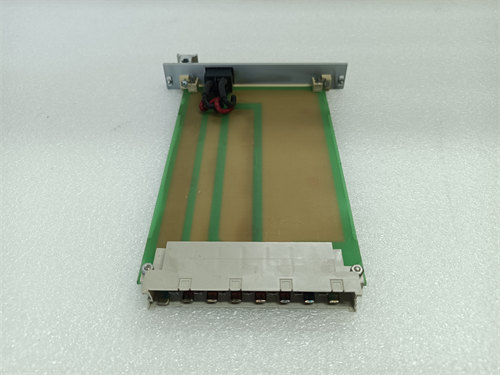

- Input/Output Type: Analog and Digital I/O (configurable)

- Number of Channels: Varies (multiple I/O channels depending on specific configuration)

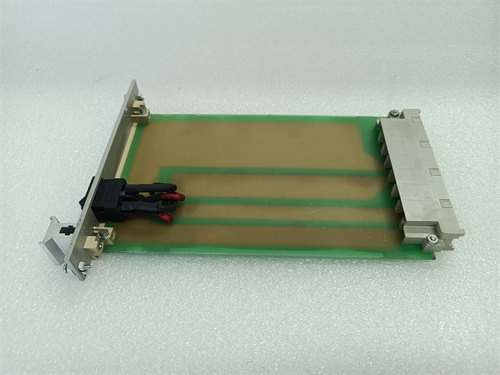

- Mounting Type: Rack-mounted (for integration into GE DCS racks)

- Operating Voltage: 24V DC (typical industrial power)

- Temperature Range: 0°C to 60°C (32°F to 140°F)

- Communication Protocols Supported:

- Modbus RTU/TCP

- Ethernet/IP

- GE proprietary communication protocols

- Size: Compact, rack-mounted design

- Power Consumption: Low power consumption, designed for efficiency

- Certification: CE, UL, CSA (safety and regulatory compliance)

Product Specifications:

-

I/O Capabilities:

- Analog Inputs and Outputs: The module offers flexibility in supporting both analog input and output configurations, allowing users to handle a range of industrial sensors and actuators.

- Digital Inputs and Outputs: Provides digital I/O channels for controlling and monitoring on/off states, ideal for discrete operations.

-

Signal Types:

- Analog Input Channels: Configurable for different input types, including voltage (e.g., 0-10V), current (e.g., 4-20mA), and resistance.

- Analog Output Channels: Supports output signals such as 0-10V, 4-20mA, and other standard control signals for actuators.

- Digital Inputs: Support for discrete on/off signals, used for devices like limit switches, safety sensors, and pushbuttons.

- Digital Outputs: Used to control devices such as solenoid valves, motors, and relays.

-

Control and Communication Capabilities:

- Modbus RTU/TCP and Ethernet/IP communication protocols for easy integration into modern industrial networks.

- The GE+WES13-3 5167-0001-0210 supports real-time data exchange, allowing for quick decision-making and control over industrial processes.

- The module can communicate with other GE DCS components for efficient coordination of tasks and alarms.

-

Redundancy and Reliability:

- The module is built with redundancy in mind, offering support for dual power supplies for fault tolerance and continuous operation.

- Integrated diagnostics provide real-time monitoring and early detection of faults to ensure smooth system operation.

-

Environmental Durability:

- Designed to withstand harsh industrial environments, the GE+WES13-3 5167-0001-0210 module operates in a wide temperature range (0°C to 60°C) and is resistant to electromagnetic interference (EMI), ensuring reliability in noisy environments.

-

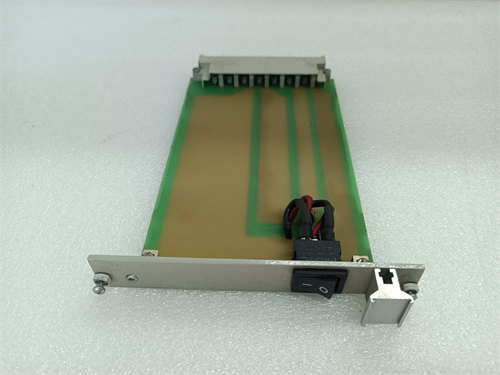

Mounting and Integration:

- The module integrates into GE DCS racks and can be easily expanded as part of a larger automation system. It supports rack-based mounting, simplifying installation and scaling of control systems.

- The system can be customized with different I/O configurations, depending on the needs of the application.

-

Power and Thermal Management:

- Low power consumption ensures energy-efficient operation while maintaining high performance.

- The thermal management design helps keep the module operating within safe temperature limits even under heavy loads.

Key Features:

- Modular I/O: Supports both analog and digital I/O configurations, making it highly flexible for various industrial applications.

- Redundancy Support: Features built-in redundancy, including dual power supply options for increased reliability in mission-critical applications.

- Real-time Communication: Provides high-speed data transfer via Ethernet/IP and Modbus protocols, ensuring timely decision-making in real-time control scenarios.

- Diagnostics and Monitoring: Offers integrated diagnostics and health checks, providing early fault detection and maintenance alerts to reduce downtime.

- Compatibility with GE DCS Systems: Seamlessly integrates with other GE automation products, ensuring a unified and efficient control system architecture.

Applications:

The GE+WES13-3 5167-0001-0210 DCS PLC Module is well-suited for a variety of industries that require advanced control systems for automation and process management. Its flexibility and rugged design make it ideal for the following applications:

-

Oil and Gas:

- Used for controlling pumps, valves, and sensors in both upstream (exploration, drilling) and downstream (refining, processing) operations.

- Provides real-time monitoring of critical parameters like pressure, flow, and temperature.

-

Power Generation:

- Control of turbines, generators, pumps, and valves in power plants, ensuring efficient energy production and distribution.

- Supports both real-time process control and system diagnostics for optimal performance.

-

Chemical Processing:

- Controls chemical reactors, mixers, and conveyors while monitoring critical variables such as pH, temperature, and flow.

- Helps ensure safe and efficient operation in highly controlled environments.

-

Water and Wastewater Treatment:

- Used in controlling pumps, filtration systems, and chemical dosing systems.

- Offers real-time monitoring of water quality parameters such as pH, turbidity, and chemical concentrations.

-

Manufacturing and Industrial Automation:

- Suitable for controlling production lines, robotic arms, and conveyor belts.

- Provides real-time process control to ensure smooth operations in complex manufacturing environments.

Conclusion:

The GE+WES13-3 5167-0001-0210 DCS PLC Module is a versatile, high-performance module designed for integration into GE’s Distributed Control Systems. With its modular I/O options, robust diagnostics, and support for advanced communication protocols, it provides flexible, reliable, and scalable solutions for demanding industrial applications. Whether in oil & gas, power generation, or water treatment, this module ensures seamless control and monitoring of critical processes. Its ease of integration with existing GE systems makes it a go-to choice for industries seeking precision, performance, and reliability in their control systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922