الوصف

Product Name

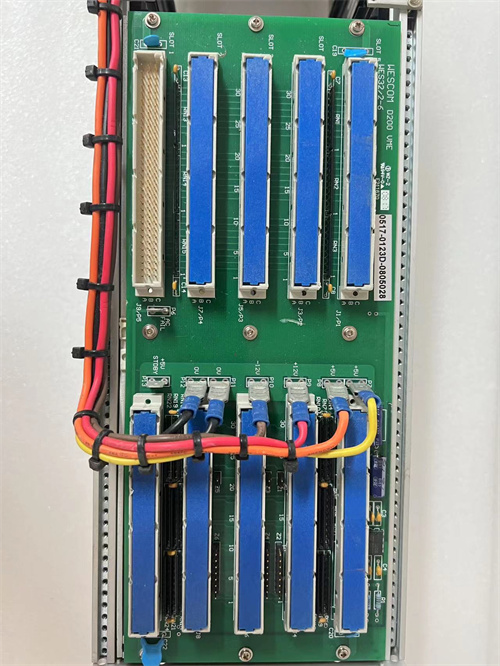

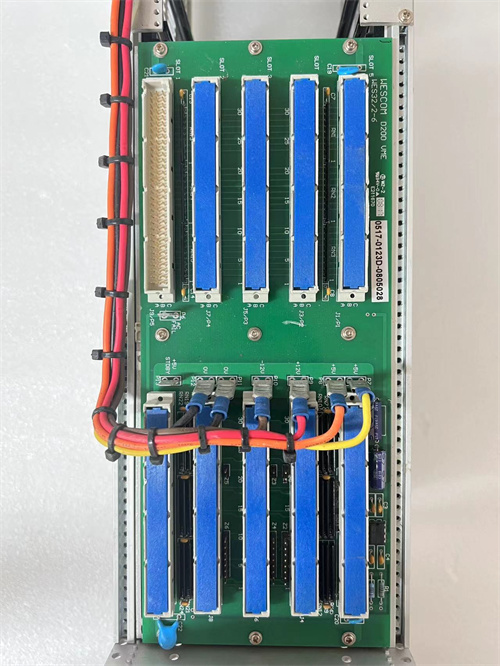

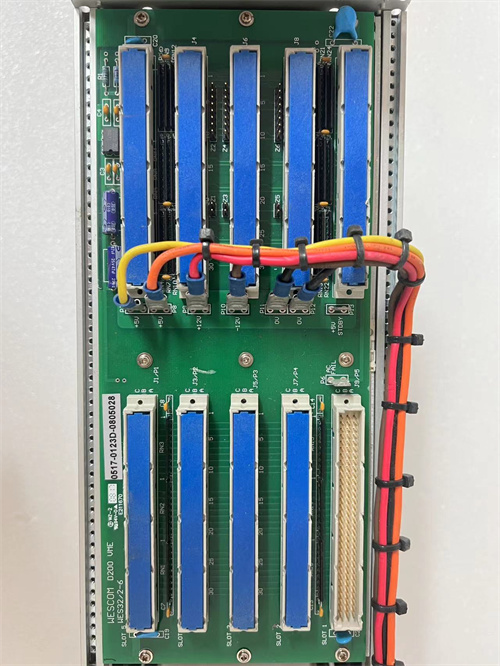

GE+WESCOM D200 VME

Product Description

GE+WESCOM D200 VME is a high-performance PLC (Programmable Logic Controller) designed to provide efficient automation solutions across various industrial applications. This model leverages advanced technology to facilitate seamless communication, control, and monitoring of industrial processes. The D200 VME is well-constructed with durability in mind, making it suitable for harsh environments often found in manufacturing plants and industrial facilities.

Equipped with an intuitive programming environment, the GE+WESCOM D200 VME enables users to quickly develop and implement automation strategies, enhancing operational efficiency and reducing downtime. This PLC model supports a range of I/O modules, allowing it to be tailored to specific application requirements.

Product Parameters

- GE+WESCOM D200 VME

- Power Supply Voltage: 24V DC

- Input Types: Digital, Analog

- Output Types: Relay, Transistor

- Communication Ports: Ethernet, RS-232, RS-485

- Programming Language: Ladder Logic, Structured Text

- Temperature Range: -20°C to +60°C

- Mounting: Rack-mounted (VME compatible)

Advantages and Features

- Scalability: The GE+WESCOM D200 VME can easily expand to accommodate additional I/O modules and devices, making it suitable for evolving applications.

- Robust Performance: Designed to operate in challenging environments, it provides reliable performance even under extreme conditions.

- Flexible Communication Options: With multiple communication ports, including Ethernet and serial communication, integration with existing systems is seamless.

- User-Friendly Interface: The intuitive programming software simplifies the setup process, allowing for rapid deployment of automation solutions.

- High-speed processing: The PLC processes data quickly, ensuring optimization of production lines and reducing latency in operations.

Application Areas and Use Cases

The GE+WESCOM D200 VME is applicable in various sectors, such as:

- Manufacturing Automation: Streamlining assembly lines and improving product quality.

- Process Control: Monitoring and controlling variables, such as temperature, pressure, and flow in industrial processes.

- Robotics: Integrating with robotic systems for tasks like welding, painting, and assembly.

- Water and Wastewater Treatment: Facilitating efficient monitoring and control of treatment processes.

For example, in a manufacturing plant, the D200 VME can be used to automate the assembly line process, reducing manual labor and increasing throughput. In a water treatment facility, it can optimize the chemical dosing systems ensuring compliance with environmental regulations.

Competitor Comparison

When compared to competitor models, such as the Siemens S7-1200 and Allen-Bradley Micro850, the GE+WESCOM D200 VME holds several advantages:

- Higher Temperature Tolerance: With a wider operational temperature range, it outperforms competitors in severe conditions.

- Greater Flexibility: The modular design of the D200 VME allows for more customized configurations according to specific application needs.

- Cost-Effectiveness: Often priced lower than equivalent competitive models, providing exceptional value for a high-performance PLC.

Selection Recommendations

When considering the GE+WESCOM D200 VME, evaluate the following factors:

- Application Requirements: Assess the I/O needs and communication protocols relevant to your projects.

- Environmental Conditions: Ensure that the temperature and vibration conditions of your operational environment are suitable for the D200 VME.

- Future Scalability: Consider future growth and how the control system may need to expand or adapt to new technologies.

Precautions

- Ensure proper grounding during installation to prevent electrical interference.

- Regularly update the firmware to maintain optimal functionality and address security vulnerabilities.

- Evaluate compatibility with existing control systems to avoid integration challenges.

We are your trusted partner, providing product models like GE+WESCOM D200 VME and other automation spare parts, along with sales and technical support. We offer special discounted prices. Please contact us, and we will be dedicated to serving you.

GE+WESCOM D200 VME

| 3BSE022360R2 ABB |

| DI803-eA ABB DCS |

| ABB 3BSE022362R2 PLC |

| AI801-eA ABB PLC |

| 3BSE020512R2 ABB PLC |

| ABB AI845-eA |

| 3BSE023675R2 PLC |

| DI810-eA ABB |

| ABB 3BSE008508R2 PLC |

| CI801-eA PLC |

| 3BSE022366R2 PLC |

| CI801-eA ABB PLC |

| DO802-eA DCS ABB |

| 3BSE022364R2 PLC |

| AO820-eA ABB PLC |

| 3BSE008546R2 ABB DCS |

| DI821-eA PLC |

| 3BSE008550R2 PLC |

| AI820-eA PLC |

| ABB 3BSE008544R2 PLC |

| AO810V2-eA ABB PLC |

| 3BSE038415R2 ABB PLC |

| TB820V2-eA ABB |

| ABB 3BSE013208R2 PLC |

| IB820V2-eA ABB PLC |

| ABB DO810-eA I/O |

| 3BSE008510R2 ABB PLC |

| ABB AI835A-eA PLC |

| 3BSE051306R2 ABB PLC |

| ABB AO845A-eA PLC |

| 3BSE045584R2 ABB DCS |

| DP840-eA ABB PLC |

| 3BSE028926R2 ABB PLC |

| ABB AI830A-eA PLC |

| 3BSE040662R2 ABB PLC |

| AI810-eA ABB PLC |

| ABB 3BSE008516R2 |

| DI811-eA ABB PLC |

| ABB 3BSE008552R2 PLC |

| DO801-eA ABB CPU |

| 3BSE020510R2 ABB CPU |

| ABB DI801-eA CPU |

| 3BSE020508R2 CPU |

| ABB AO801-eA I/O |

| 3BSE020514R2 ABB |

| AO845A PLC |

| 3BSE045584R1 PLC |

| ABB TB40A 3BSE037760R1 PLC |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922