الوصف

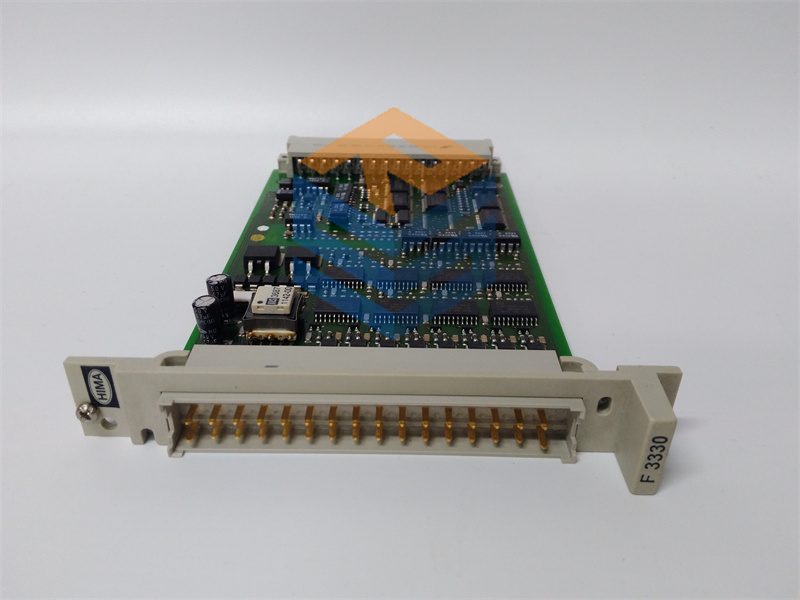

Product Name:

HIMA F3330 DCS PLC Module

Product Description:

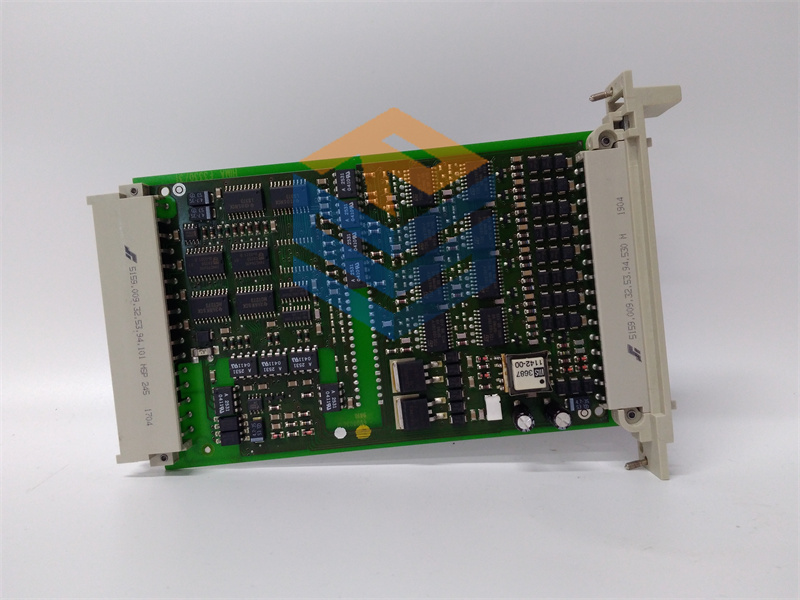

The HIMA F3330 is part of the HIMA Safety PLC (Programmable Logic Controller) family and is designed for use in Safety Instrumented Systems (SIS) and Distributed Control Systems (DCS). It offers highly reliable, fault-tolerant, and high-performance control capabilities, essential for critical safety and process automation applications.

The F3330 module is typically used for applications requiring functional safety, such as process industry automation, oil & gas, chemical plants, and other industrial sectors where high safety standards are crucial. This module ensures that the system meets safety standards such as IEC 61508, ISO 13849, and IEC 61511 for functional safety.

Product Parameters:

- Type: Safety PLC Module (HIMA F3330)

- Application Area:

- Distributed Control Systems (DCS)

- Safety Instrumented Systems (SIS)

- Industry Standards:

- IEC 61508

- ISO 13849

- IEC 61511

- Key Features:

- Safety-critical control

- Redundant communication

- High fault tolerance and reliability

- Configurable I/O capabilities

Specifications:

-

Power Supply:

- Input Voltage: 24V DC

- Power Consumption: Typically 10W (depending on the configuration)

-

Processor and Memory:

- CPU Type: HIMA’s custom high-performance processor

- Program Memory: High-capacity for program storage (typically > 500KB)

- Non-Volatile Memory: For storing program and configuration data securely.

- Processing Speed: Fast real-time processing for critical control functions.

-

Communication:

- Redundant Communication: Supports redundant networks for ensuring reliability (e.g., Ethernet, Profibus, or HIMA proprietary communication protocols).

- Modular Communication: Supports communication with various DCS, SCADA, and PLC systems.

- Fieldbus Support: Integrates with field devices through different protocols like Modbus, Profibus, HART, and Foundation Fieldbus.

-

Input/Output (I/O) Modules:

- Digital Inputs/Outputs (I/O): Configurable digital I/O for both normal and safety-critical signals (standard and fault-tolerant configurations).

- Analog I/O: Support for analog signal processing with fault tolerance for critical operations.

- Signal Conditioning: Built-in capabilities for signal conditioning and fault detection.

-

Fault Tolerance & Diagnostics:

- Redundancy: Fully redundant configurations for safety-critical applications, including power, communication, and processing.

- Self-Diagnostics: Real-time diagnostics for all critical functions and components, ensuring that any failure is immediately detected and handled.

- Fail-Safe Design: The system is designed to meet SIL 3 (Safety Integrity Level) for high-demand systems.

-

Safety Standards:

- SIL 3 Compliant: Complies with IEC 61508 SIL 3 standards for functional safety.

- SIL 2 or SIL 3: Configurable for SIL 2 or SIL 3 applications based on the safety requirements.

- IEC 61511 & ISO 13849: Meets the requirements for process safety and machinery safety standards.

-

Environmental Conditions:

- Operating Temperature Range: Typically from -20°C to +60°C.

- Storage Temperature Range: -40°C to +85°C.

- Humidity: Typically, 5% to 95% relative humidity (non-condensing).

- Vibration Resistance: Designed for industrial environments with moderate vibration levels.

-

Mounting:

- Mounting Type: Rail-mounted in a standard DIN-rail enclosure, ensuring easy installation and maintenance.

- Module Size: Compact form factor for easy integration into control cabinets or racks.

-

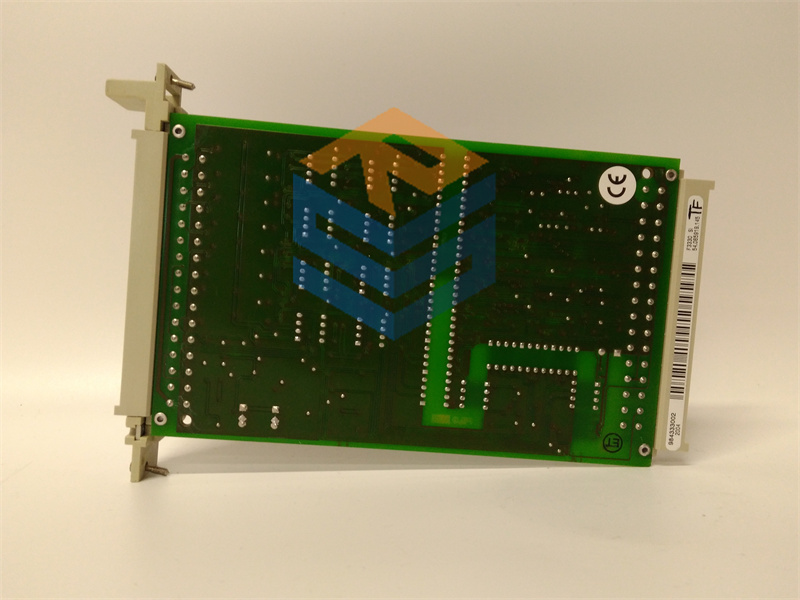

Certifications:

- CE Certification: For use in European markets.

- FM/CSA/ATEX (optional): Available for hazardous locations depending on the application.

- IECEx (optional): Available for explosive environments.

Key Features:

-

High Reliability and Fault Tolerance:

The HIMA F3330 module is designed with redundant processing and communication paths, offering high availability for critical processes and applications. -

Safety and Performance:

Supports high-performance control and meets functional safety requirements for industrial applications with high demand for safety (e.g., SIL 3). -

Flexible Integration:

The module is highly flexible and can integrate with various control systems (DCS, PLCs, SCADA systems) and can interface with a wide range of field devices. -

Real-time Diagnostics:

Constant self-checks and diagnostics to ensure operational integrity, allowing immediate detection of faults and safe shutdown in case of critical errors. -

Scalability and Modularity:

The system is modular and can be easily expanded to meet the growing needs of industrial facilities, with scalable I/O modules and redundant systems.

Applications:

- Oil & Gas: Safety control for upstream and downstream processes (e.g., pressure relief, emergency shutdown).

- Chemical Processing: Managing critical processes with high safety demands.

- Power Generation: Ensuring safety control in power plant operations, such as turbine control, emergency shutdown, etc.

- Pharmaceuticals: Ensuring safety in automated production lines.

- Food & Beverage: Regulatory compliance for production safety systems.

Conclusion:

The HIMA F3330 is an advanced safety PLC module that integrates seamlessly into Distributed Control Systems (DCS) and Safety Instrumented Systems (SIS), providing high-performance, fault-tolerant, and SIL-compliant control capabilities. Its ability to meet stringent safety standards makes it an ideal choice for critical, safety-related applications in industries like oil & gas, chemicals, power generation, and more.

BENTLY 3300/16-14-01-03-00-00-01

BENTLY 3500/15

BENTLY 3500/15

BENTLY 3500/15

BENTLY 3500/20

BENTLY 3500/20

BENTLY NEVADA 125760-01

BENTLY NEVADA 125768-01

BENTLY NEVADA 129478-01

BENTLY NEVADA 3500

BENTLY NEVADA 3500

BENTLY NEVADA 3500/05-01-01-00-00-00

BENTLY 1X35668

BENTLY 3500/22M

BENTLY 3500/25

BENTLY 3500/42M

BENTLY 3500/42M

BENTLY 3500/42M

BENTLY 3500/42M

BENTLY 3500/42M

BENTLY 330730-040-00-00

Bently 330103-00-06-10-02-00

Bently 330130-040-00-00

BENTLY 330130-045-00-00

BENTLY 330130-045-00-00

BENTLY 330130-045-00-00

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922