الوصف

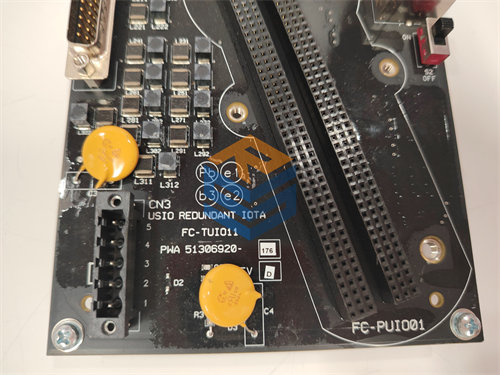

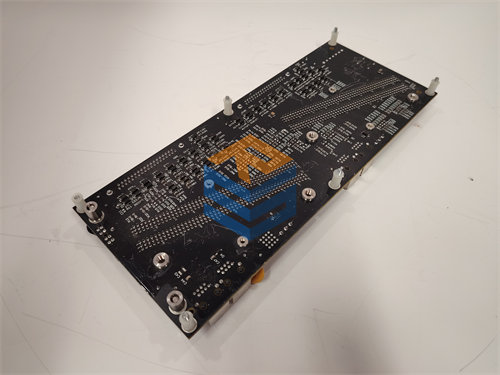

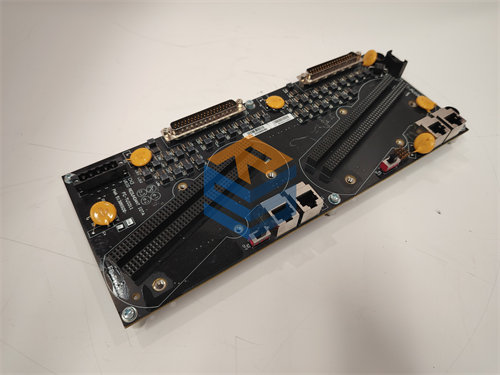

HONEYWELL+FC-PUIO01 PLC Module

Product Name:

HONEYWELL+FC-PUIO01 – PLC Module

Product Description:

The HONEYWELL+FC-PUIO01 is a versatile Programmable Logic Controller (PLC) I/O module used in Honeywell’s ControlEdge™ and Experion® systems. This module provides flexible input/output (I/O) functionality for industrial automation and process control applications. Specifically designed to work in high-performance, real-time control environments, the FC-PUIO01 ensures seamless integration with Honeywell’s advanced control and safety systems. It is ideal for use in industries like oil and gas, chemical, power generation, and manufacturing, where precise, reliable control of field devices is essential.

The FC-PUIO01 supports modular I/O configuration, allowing for flexible system expansion, and is capable of managing both digital and analog signals. Its integration with Honeywell’s Experion PKS (Process Knowledge System) and ControlEdge Controllers enhances system-wide performance, diagnostics, and troubleshooting. The module is built to meet industrial standards and provides reliable performance even in harsh environments.

Key Features:

-

Modular I/O Configuration:

- The FC-PUIO01 module offers flexible modular I/O, supporting a wide range of input and output devices such as sensors, actuators, and field instruments. The system can be scaled as needed for different process requirements.

-

Digital and Analog I/O:

- Supports digital inputs and outputs for on/off devices like switches and relays, as well as analog inputs and outputs for continuous process signals like pressure, temperature, and flow.

-

Real-Time Processing:

- Designed for real-time control applications, the module supports high-speed data processing for critical process control.

-

Easy Integration:

- Seamlessly integrates into Honeywell Experion or ControlEdge systems, providing enhanced control and visibility across the entire process.

-

Advanced Diagnostics:

- Built-in diagnostic features allow for early fault detection, status monitoring, and preventive maintenance to reduce downtime and improve system reliability.

-

Wide Operating Range:

- The FC-PUIO01 is designed to operate in extreme industrial conditions, supporting high temperatures and offering wide voltage tolerance to accommodate diverse process environments.

-

Safety Standards Compliance:

- Fully compliant with industry safety standards, ensuring its suitability for safety-critical applications in hazardous environments.

-

Scalability and Expandability:

- The module can be expanded with additional I/O modules to scale the system for growing process requirements.

-

Redundancy:

- Built-in support for redundant systems, ensuring high availability and operational continuity in critical process control applications.

-

Field Device Interface:

- Compatible with a broad range of field devices, making it ideal for applications across different industries.

Product Parameters & Specifications:

General Information:

-

Model:

- HONEYWELL+FC-PUIO01

-

Brand:

- Honeywell

-

Category:

- Programmable Logic Controller (PLC) I/O Module

-

Control Platform:

- Honeywell Experion® PKS, ControlEdge™

-

Application:

- Industrial Automation, Process Control, Real-Time Monitoring

-

Part Number:

- FC-PUIO01

Power Supply:

-

Nominal Voltage:

- 24V DC (standard industrial control power)

-

Input Voltage Range:

- 18V to 30V DC

-

Power Consumption:

- Typically 10W to 30W, depending on configuration and connected I/O.

Operating Conditions:

-

Operating Temperature Range:

- -40°C to +70°C (-40°F to 158°F), suitable for harsh industrial environments.

-

Storage Temperature Range:

- -40°C to +85°C (-40°F to 185°F), ensuring safe storage under extreme conditions.

-

Relative Humidity:

- 5% to 95% (non-condensing), supporting reliable operation in humid environments.

-

Vibration Resistance:

- Meets industrial vibration standards for resilience in manufacturing and process control environments.

-

Protection Rating:

- IP20 (suitable for enclosed environments or cabinets).

I/O Specifications:

-

Digital I/O:

- Supports digital inputs and digital outputs for binary signals such as on/off switches, relays, and alarms.

-

Analog I/O:

- 4-20mA or 0-10V analog inputs and outputs, typically for sensors like temperature, pressure, and flow devices.

-

Field Device Support:

- Compatible with a wide range of field instruments including temperature transmitters, pressure sensors, and actuators.

-

Channel Configuration:

- Supports configurable I/O channels for flexible system design, enabling the connection of different devices based on application needs.

-

Communication Protocols:

- Integrated with Honeywell’s proprietary communication protocols and can support standard industrial protocols for field communication (e.g., Modbus, Profibus, HART).

Performance & Control Features:

-

Processing Speed:

- Optimized for real-time control, capable of processing high-frequency input signals in fast response times.

-

Control Algorithms:

- Supports advanced control algorithms including PID control and sequence control for process automation.

-

Fault Tolerance:

- Offers redundancy and fault-tolerant capabilities for high-availability systems in safety-critical applications.

-

Diagnostic Features:

- Provides detailed diagnostics such as signal integrity checks, device status monitoring, and fault reporting to enhance uptime.

Compliance & Certifications:

-

Safety Certifications:

- Complies with industry safety standards such as IEC 61508 (Functional Safety) and IEC 61511 (Safety Instrumented Systems) for use in safety-critical systems.

-

Electromagnetic Compatibility (EMC):

- Meets EMC standards to prevent electromagnetic interference and ensure stable operation in noisy industrial environments.

-

Environmental Compliance:

- Adheres to global environmental standards to minimize impact and ensure sustainable operations.

Applications:

-

Oil & Gas:

- Ideal for exploration, drilling, refining, and pipeline monitoring, where real-time data processing and safety are crucial.

-

Chemical Processing:

- Used for controlling chemical reactors, mixers, and other critical operations requiring precise measurement and control.

-

Power Generation:

- Employed in the control of turbines, generators, and energy distribution systems in power plants, ensuring continuous operation and safety.

-

Manufacturing and Automation:

- Used in automated production lines, monitoring equipment, and process control systems that require real-time inputs/outputs.

-

Water & Wastewater Treatment:

- Helps in the control and monitoring of water treatment facilities, ensuring that critical systems like pumps, valves, and flow meters are accurately managed.

Summary of Key Features:

- Modular and scalable I/O for flexible integration in control systems.

- Digital and analog I/O support for a wide range of field devices.

- Real-time data processing and advanced control algorithms for process automation.

- Built-in diagnostics for system health monitoring and fault detection.

- Compliant with functional safety standards (SIL, IEC).

- High environmental tolerance and redundant systems for critical operations.

Let me know if you need further details or specific technical data!

RadisysSC815E PLC

1485C-P1-C600

2711-K10C15L1 PLC

2711-T9C10

140U-K0X3 PLC

6181P-17TPXPSS PLC

SCE904AN-001-01

2098-DSD-HV220

SYNERGIC-5000

omron-NT600MDT-122 PLC

PR6423/010-030+CON021 PLC

5202-DFNT-MCM4 PLC

3HAC14546-2/04A PLC

DSQC601 PLC

DSQC604

PXIE-8840 PLC

PXI-4461 PLC

P1161A PLC

0190-35452 PLC

1326AB-B420E-M2K4L

831006003 PLC

1326-CCU-015-VMI-3D PLC

VE3006

VE3051CO CPU

VE5009 CPU

4003S6B1 PLC

4003S2B1 PLC

4001S2T2B4 PLC

4002S1T2B5 PLC

4006P2 CPU

VE4050S2K1C0 PLC

80025-523-09 PLC

R900938012 PLC

R900937998 PLC

ABB-AI890 PLC

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922