الوصف

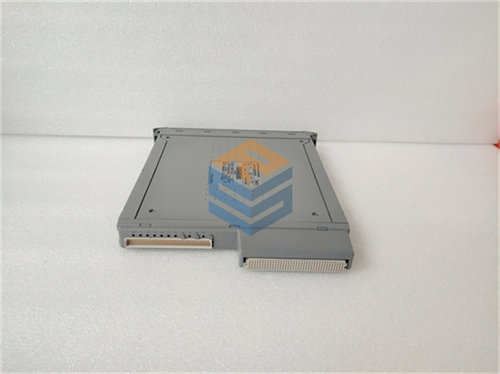

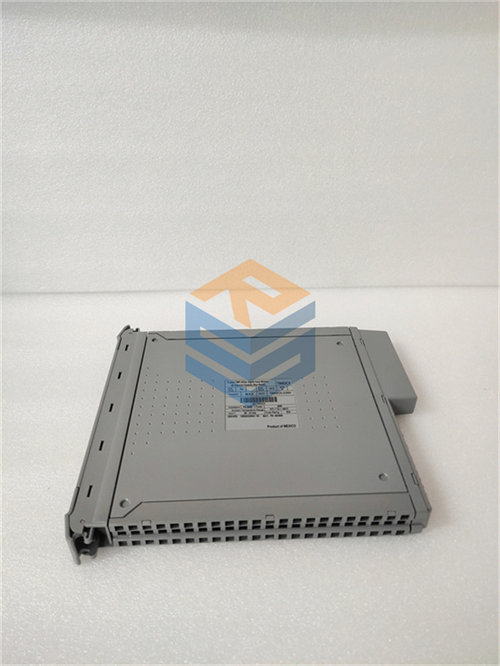

ICS TRIPLEX T8403C – Overview and Specifications

The ICS Triplex T8403C is a module from the ICS Triplex product line, typically used in safety systems, particularly in critical process control and safety applications. It is designed to offer high redundancy, fault tolerance, and real-time processing for industrial automation systems that require high safety integrity. The T8403C is part of the Triplex T8000 series, a family of programmable safety controllers and I/O modules.

This particular model is often employed in industries such as oil and gas, chemical processing, power generation, and other mission-critical environments that require SIL (Safety Integrity Level) certification for safety-critical systems.

Key Features:

-

Safety Integrity:

- Designed for SIL 3 and SIL 2 applications (Safety Integrity Level), which is essential for critical operations where human safety and process integrity are a priority.

- Ensures the safety of machinery, personnel, and the environment by continuously monitoring system health and implementing corrective actions when necessary.

-

Redundancy:

- Redundant architecture to minimize the risk of failure. It can operate in a dual-redundant configuration, ensuring high availability and reliability.

- Supports redundant communication pathways and power supplies, ensuring the system remains operational even if one path fails.

-

Real-Time Processing:

- Offers real-time control with high-speed data processing, ideal for safety-critical systems where immediate response times are essential to prevent hazards.

-

Communication Protocols:

- Integrates with a variety of communication protocols, allowing the T8403C to interface with other control systems, SCADA systems, and field devices.

- Typically supports Modbus, Profibus, Ethernet/IP, and proprietary protocols depending on the specific configuration.

-

Flexibility and Modular Design:

- Flexible I/O configurations to meet specific process requirements. The T8403C can be part of a larger system with modular expansion options.

- Supports various digital and analog I/O configurations, including temperature sensors, pressure transducers, flow meters, etc.

-

Diagnostics and Monitoring:

- Includes built-in diagnostic features that continuously monitor the health of the system. Faults are detected and isolated in real-time, and appropriate corrective actions are taken.

- Self-diagnostic capabilities for continuous health checks and automatic error detection.

-

High Availability:

- The system can continue functioning in the event of a hardware or software failure due to its fault-tolerant design.

- Provides automatic failover capabilities to ensure continuous safety and process operation without interruption.

Product Specifications:

Electrical & Power Supply:

- Power Supply: Typically 24V DC, but specific configurations may vary depending on the system setup.

- Current Consumption: Varies based on system load and configuration, typically low-power to reduce operational costs in critical systems.

- Redundant Power: Designed to work with dual power supplies for continuous operation even if one fails.

Processor & Memory:

- Processor Type: Typically a 32-bit processor capable of handling high-speed data processing and complex algorithms.

- Memory: Ample memory capacity for handling complex control programs, typically RAM and non-volatile memory for storing program data and diagnostics.

I/O Configuration:

- Digital I/O: Supports a variety of digital input and output configurations. Common for controlling binary devices like relays and switches.

- Analog I/O: Supports analog inputs and outputs for handling continuous process signals like temperature, pressure, and flow.

- High-Speed I/O: Capable of handling fast inputs and outputs for time-sensitive applications.

Communication Protocols:

- Modbus RTU/TCP, Profibus, Ethernet/IP: Common industrial communication standards that allow the T8403C to communicate with PLCs, SCADA systems, and remote devices.

- Redundant Communication Paths: Ensures no communication loss during network failures or hardware faults.

Environmental Specifications:

- Operating Temperature: Typically ranges from 0°C to 60°C (32°F to 140°F), designed for industrial environments.

- Storage Temperature: -20°C to 70°C (-4°F to 158°F).

- Humidity: Can operate in environments with 5% to 95% relative humidity (non-condensing).

- Vibration and Shock Resistance: Designed to meet industrial standards for vibration and shock resistance.

Fault Tolerance & Diagnostics:

- Self-Diagnostics: Built-in tools for continuous monitoring of internal systems and field devices.

- Fault Isolation: Ability to pinpoint faults in the system and provide detailed diagnostic information.

- Fail-Safe Operation: Ensures the system defaults to a safe state in case of failure, preserving personnel and equipment safety.

Applications:

- Oil and Gas: Used in exploration, refining, and petrochemical plants to control safety-critical systems such as pressure relief valves, gas detection, and emergency shutdowns.

- Chemical Processing: Involved in process control, ensuring safe operation in hazardous environments.

- Power Generation: Used for controlling critical equipment such as turbines, boilers, and generators, where any failure can lead to catastrophic consequences.

- Water Treatment: Used to control safety-critical equipment and ensure the continuous operation of water and wastewater treatment plants.

Conclusion:

The ICS Triplex T8403C is a high-integrity, safety-focused I/O and control module used in mission-critical applications. Designed to meet SIL 3 safety standards, it provides redundancy, real-time processing, and robust fault detection. Its modular design, flexible I/O configurations, and support for multiple communication protocols make it a versatile choice for industries where safety and reliability are paramount. Whether in oil and gas, chemical processing, or power generation, the T8403C ensures that critical systems remain operational even under the most demanding conditions.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922