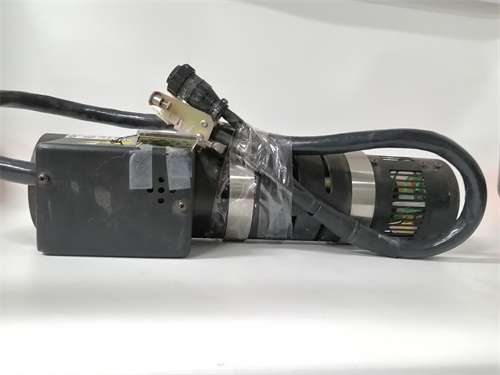

الوصف

The JDSU 2213-75TSLKTB DCS PLC Module is likely a product from JDSU, a company renowned for its testing and measurement instruments, although the product you’re referring to appears to be related to DCS (Distributed Control System) or PLC (Programmable Logic Controller) applications in industrial settings. Unfortunately, I don’t have specific information on the JDSU 2213-75TSLKTB PLC module itself, but I can provide a general outline for a DCS/PLC module from a similar category based on typical industry standards.

Here’s a product description and specification breakdown based on the general characteristics of a DCS/PLC module:

Product Name:

JDSU 2213-75TSLKTB DCS PLC Module

Product Description:

The JDSU 2213-75TSLKTB is a specialized DCS (Distributed Control System) PLC module designed for industrial automation and process control. It serves as the brain of a control system, providing processing power, communications, and interfacing capabilities for monitoring and controlling complex industrial processes. This module is intended for use in a broad array of applications, including manufacturing, energy management, process automation, and telecommunication systems.

The 2213-75TSLKTB is particularly focused on providing reliable and efficient control in environments requiring high performance, flexibility, and uptime. It typically integrates seamlessly with both sensors and actuators to ensure real-time data acquisition, decision-making, and control of operational processes.

Key Features:

- High-performance CPU: Offers fast processing and real-time control capabilities, ensuring smooth and accurate process automation.

- Flexible I/O Configurations: Supports a wide range of digital and analog I/O modules, providing scalability and flexibility for various application needs.

- Multiple Communication Protocols: Compatible with a variety of communication standards such as Modbus, Ethernet/IP, Profibus, and Fieldbus, enabling efficient data exchange with other control systems and field devices.

- Redundancy Support: Ensures high availability and fault tolerance through options like hot standby redundancy, ensuring uninterrupted operation even during hardware failures.

- Modular Design: The system is modular, allowing easy expansion with additional modules or upgraded components to scale according to evolving system requirements.

- Built-in Diagnostics: The module includes comprehensive diagnostic capabilities to monitor system health, detect faults, and alert operators to potential issues before they result in downtime.

- Real-time Control: Capable of providing high-speed control for time-sensitive applications with minimal latency.

Product Parameters & Specifications:

1. General Specifications:

- Model Number: JDSU 2213-75TSLKTB

- System Type: DCS (Distributed Control System) PLC Module

- Processor: High-speed CPU optimized for real-time processing.

- Form Factor: Typically designed for modular installation within a control panel or rack-mounted configuration.

- Target Applications: Industrial automation, telecommunication systems, energy control, process automation.

2. Electrical Specifications:

- Operating Voltage: Typically 24V DC, compatible with a variety of industrial power supplies.

- Power Consumption: Power requirements typically range from 10W to 50W depending on the system configuration and modules attached.

- Signal Types:

- Digital Inputs/Outputs: 24V DC logic inputs and outputs.

- Analog Inputs: Supports inputs like 0-10V or 4-20mA for sensors.

- Analog Outputs: Output ranges include 0-10V or 4-20mA.

- Relay Outputs: Typically used for controlling external devices requiring higher power.

3. Communication Interfaces:

- Ethernet Ports: Typically features 2 Ethernet ports for network connectivity (for communication with other devices or systems).

- Fieldbus Protocols: Supports multiple industrial fieldbus protocols such as:

- Modbus RTU/TCP

- Profibus DP

- CANopen

- Ethernet/IP

- DeviceNet

- Serial Ports: For connection to serial devices and older systems, often RS232/RS485.

- OPC Compliance: Includes OPC UA/DA support for integration with higher-level control systems or supervisory control and data acquisition (SCADA) systems.

4. Performance Specifications:

- CPU Performance: Equipped with a powerful CPU capable of processing control logic, diagnostic data, and communications in real-time.

- Cycle Time: Typical scan cycle times range from 1 ms to 10 ms, depending on the number of I/O points and complexity of the logic.

- Memory: Available system memory ranges between 512MB to 4GB, allowing for large-scale program storage and real-time data handling.

- I/O Points: Capable of handling a large number of I/O modules and devices with high-density input and output configurations.

- Data Throughput: High-speed communication interfaces ensuring low-latency and high-throughput data processing.

5. I/O Support:

- Digital I/O: Digital inputs and outputs for on/off type signals.

- Analog I/O: Analog inputs and outputs for continuous data signals (e.g., temperature, pressure, flow rate).

- Modular I/O Configuration: The module can be expanded with various types of I/O modules such as discrete inputs/outputs, analog inputs/outputs, or specialized modules for specific sensors.

6. Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F), depending on specific product configurations.

- Storage Temperature: Typically -40°C to 85°C (-40°F to 185°F).

- Humidity: Operating in 5% to 95% relative humidity, non-condensing.

- Vibration Resistance: Typically rated for 5g vibration resistance for industrial-grade environments.

- Shock Resistance: Rated for 15g shock tolerance.

7. Redundancy & Fault Tolerance:

- Redundant Power Supply: Some configurations may offer dual power supply options to maintain operation in case of power failure.

- CPU Redundancy: Hot standby configurations available to ensure zero downtime in mission-critical applications.

- Diagnostic Monitoring: Built-in diagnostic features to monitor system health and alert users of potential issues, including communication errors, power supply failure, and sensor malfunctions.

8. Safety & Security Features:

- Access Control: Features like password protection and role-based access for securing the system from unauthorized access.

- Data Integrity: Supports secure communications with encryption protocols to protect data integrity and prevent tampering.

- SIL Compliance: May be compliant with Safety Integrity Levels (SIL), depending on the application, to meet industrial safety standards.

Application Areas:

- Industrial Automation: Used in manufacturing plants, process control, and machine automation for real-time monitoring and control.

- Energy Systems: Applied in power plants, renewable energy systems, and energy grid control.

- Telecommunications: Used in telecommunication networks for monitoring network operations and managing communication infrastructure.

- Transportation: Implemented in automated transportation systems for managing signals, gates, and vehicle coordination.

- Oil & Gas: Ideal for pipeline monitoring, refinery operations, and pump control systems in the oil and gas industry.

Conclusion:

The JDSU 2213-75TSLKTB DCS PLC Module is designed to offer high-performance processing, flexible I/O configurations, and reliable communication capabilities for a wide variety of industrial control applications. Whether in energy, manufacturing, or telecommunications, this module provides robust functionality with a focus on redundancy, fault tolerance, and real-time control for critical applications.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922