الوصف

Product Name:

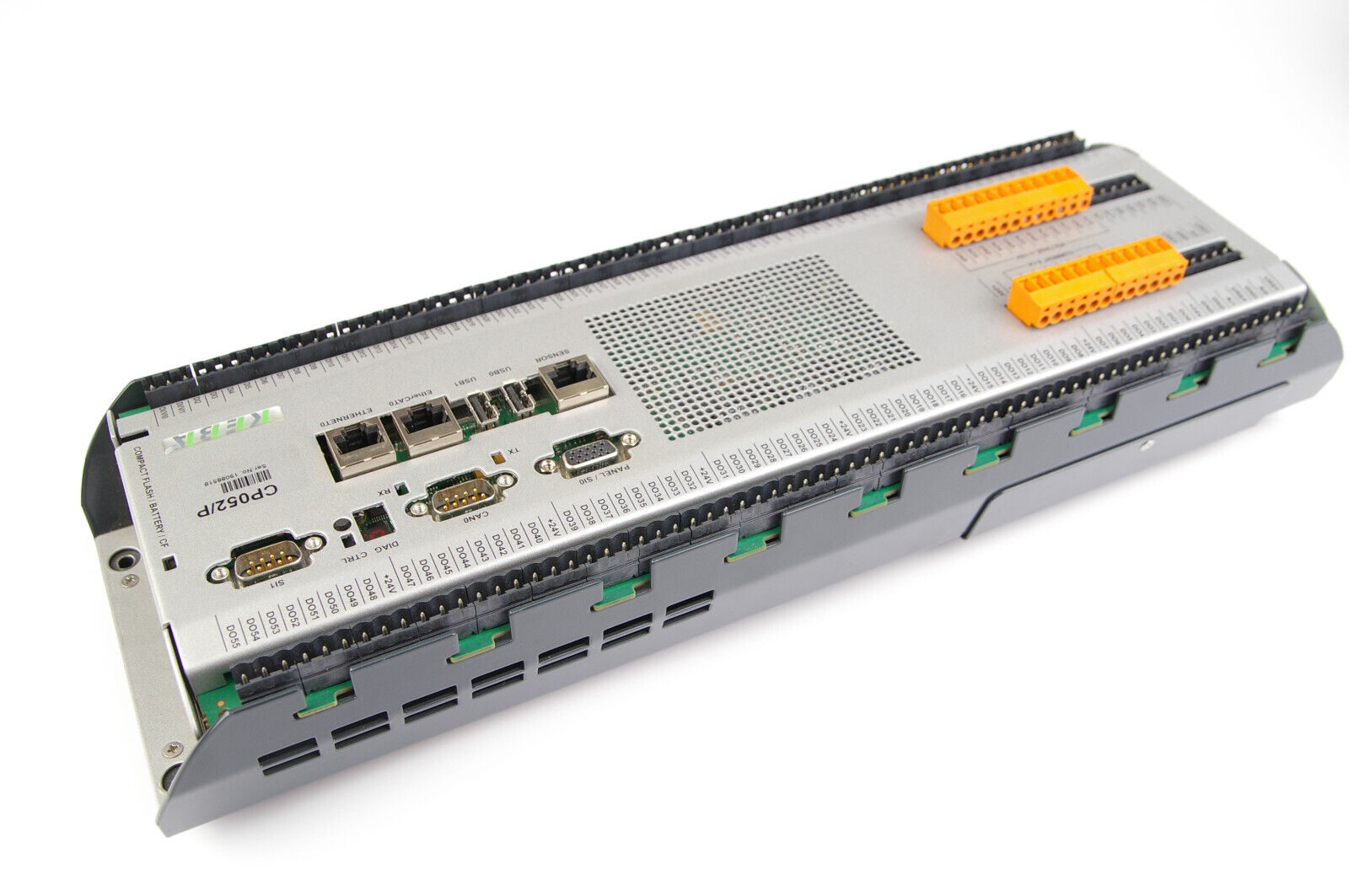

KEBA Kemro K2-200 Programmable Logic Control (PLC) Module

Rev 09 24V DC CP031/Z DCS PLC Module

Product Description:

The KEBA Kemro K2-200 is a Programmable Logic Controller (PLC) specifically designed for industrial automation and process control applications. As part of the Kemro K2 series, this DCS (Distributed Control System) PLC Module offers high-performance capabilities for real-time control, data processing, and communication. It operates with a 24V DC power supply, making it suitable for integration into industrial environments where efficient, scalable, and reliable control systems are required.

The K2-200 PLC offers flexibility in control and monitoring through its compact, modular architecture. It’s perfect for controlling machinery, production lines, and complex processes with high reliability and precision. This module supports various I/O expansions and communication protocols, making it ideal for large-scale automation systems in industries such as manufacturing, robotics, and process control.

Key Features:

- Compact and modular design allows for easy system expansion.

- Supports high-performance real-time control and data processing.

- Offers flexibility in communication protocols for easy integration with other control systems.

- Operates with a 24V DC power supply, suitable for industrial power setups.

- Designed to meet the demands of automation, machine control, and process control.

- Reliable for long-term use in harsh industrial environments.

Product Parameters:

-

Model Number:

KEBA Kemro K2-200, Rev 09, CP031/Z -

System Type:

Distributed Control System (DCS) PLC Module -

Power Supply:

24V DC, commonly used in industrial automation systems. -

Operating Temperature Range:

Typically 0°C to 50°C, adaptable to various environments. -

Communication Protocols:

Likely supports protocols like Modbus, EtherCAT, or other industrial protocols, depending on configuration. -

I/O Expansion:

Expandable with additional I/O modules for increased control capabilities. -

Processor:

High-performance processor designed to handle real-time control tasks efficiently. -

Size and Mounting:

Compact design, typically for mounting in control panels or industrial equipment.

Product Specifications:

-

Processor and Performance:

- Equipped with a high-performance CPU to handle complex, time-sensitive automation tasks.

- Real-time control and fast data processing capabilities to handle motion control, CNC applications, and other industrial tasks.

- Optimized for industrial environments that require fast response times and high reliability.

-

Memory and Storage:

- The K2-200 typically features RAM sufficient to handle control programs and data, ranging from 256 MB to 512 MB or more, depending on the configuration.

- The module also includes flash memory to store control programs, configurations, and system logs, usually ranging from 128 MB to 256 MB.

-

Modular I/O Expansion:

- The K2-200 is designed to be modular, allowing for the addition of various digital, analog, and specialty I/O modules.

- Supports expansions for different input/output requirements, such as sensor inputs, actuator control, motion control, and more.

- Up to several hundred I/O points may be supported depending on system configuration and connected expansion modules.

-

Communication Protocols:

- The Kemro K2-200 supports standard communication protocols like Ethernet/IP, Modbus TCP, Profibus, or EtherCAT (depending on the specific version and configuration), allowing for seamless integration into industrial networks.

- This enables easy connectivity with other PLCs, HMI (Human-Machine Interface), SCADA systems, and field devices for continuous monitoring and control.

-

Safety and Reliability:

- Safety features such as safe torque off (STO), emergency stop integration, and fail-safe modes are likely supported.

- Designed with high reliability to withstand harsh industrial environments, including exposure to dust, temperature fluctuations, and vibrations.

- Compliance with international safety standards like ISO 13849 and IEC 61508.

-

Energy Efficiency:

- Optimized for low power consumption, making it efficient for long-term operation in industrial settings where energy costs are a consideration.

- The 24V DC power supply ensures compatibility with common industrial power systems.

-

Temperature and Environmental Resistance:

- The module is designed to withstand various environmental challenges typical in industrial environments:

- Temperature Range: Typically operates in the range of 0°C to 50°C or higher, depending on the specific model and environmental conditions.

- Protection: Likely has an IP20 protection rating, making it suitable for mounting in control cabinets or panels with minimal exposure to dust and moisture.

- Vibration and EMI Resistance: Built to handle vibrations and electromagnetic interference (EMI), ensuring stability in noisy industrial environments.

- The module is designed to withstand various environmental challenges typical in industrial environments:

-

Scalability and Flexibility:

- The Kemro K2-200 can be easily scaled by adding additional modules to extend I/O capabilities and functionality.

- It is capable of integration into larger systems where the module’s flexibility allows it to control a wide variety of devices, ranging from simple sensors to complex machinery.

- Advanced diagnostics and system monitoring ensure that users can easily monitor the health of the system, enabling proactive maintenance.

-

Interfaces and Ports:

- The module comes with Ethernet ports, serial communication interfaces, or optional fieldbus interfaces (depending on configuration) for connecting to other controllers or devices in the network.

- Additional communication ports for HMI integration, remote monitoring, or SCADA communication are also commonly available.

Applications:

The KEBA Kemro K2-200 PLC module is used in a wide range of industrial applications, such as:

- Manufacturing Automation: Control of automated production lines, assembly stations, or packaging systems.

- CNC Machinery Control: Used to control CNC machines for precise manufacturing and machining processes.

- Robotics: Real-time control of robotic arms, automated material handling, and sorting systems.

- Process Control: Used for managing continuous or batch processes, such as chemical production, food processing, and pharmaceutical manufacturing.

- Material Handling: Managing conveyor systems, sorting lines, and automated warehouses.

- Energy Management: Used in energy optimization and control systems to monitor and manage power usage across various industrial operations.

Conclusion:

The KEBA Kemro K2-200 is a versatile, reliable, and powerful PLC module ideal for demanding industrial automation and process control environments. With its modular design, high performance, and support for various communication protocols, it offers great flexibility and scalability for applications ranging from manufacturing automation to robotics and complex process control.

Let me know if you need more detailed specifications, datasheets, or any further information!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922