الوصف

Product Name:

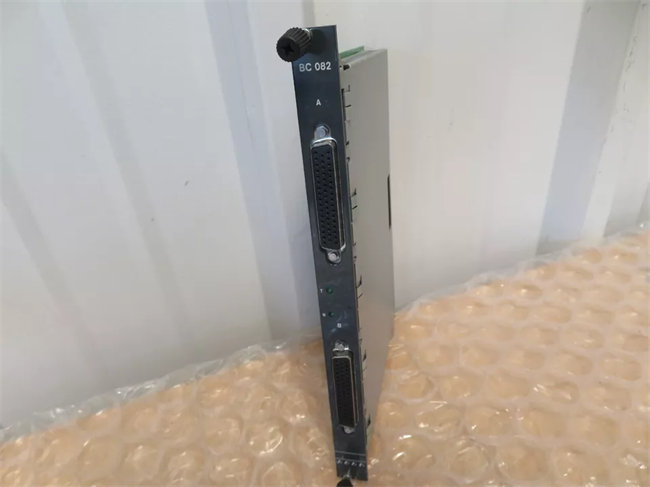

550 Ton Borche Injection Molding Machine – 2013 Model (19109-168) DCS PLC Module

Product Description:

The Borche 550 Ton Injection Molding Machine (2013 Model, 19109-168) is a highly advanced high-tonnage injection molding machine designed for high-precision and high-speed production processes in industries such as automotive, electronic components, and consumer goods. This machine is equipped with a DCS (Distributed Control System) PLC Module, which enables efficient, automated, and precise control over the entire molding process.

With a clamping force of 550 tons, the Borche machine can handle large, complex molds, delivering high productivity and consistent quality for large-scale manufacturing needs. The DCS PLC Module is an integral part of the system, providing real-time monitoring, diagnostics, and control of critical components, such as the injection unit, clamping system, and hydraulic circuits, ensuring optimal performance.

The 2013 model is engineered with advanced servo-hydraulic technology, offering energy-efficient performance, reduced operational costs, and enhanced precision. The user-friendly interface allows operators to easily configure, monitor, and control the injection molding process, making it suitable for both small and large production runs.

Product Parameters:

- Model Number: 19109-168 (2013)

- Manufacturer: Borche Machinery

- Type: Injection Molding Machine

- Clamping Force: 550 Ton

- Injection Unit:

- Screw Diameter: 50 mm – 90 mm (varies based on configuration)

- Injection Pressure: 2500-3000 bar

- Injection Volume: 1600 cm³ (varies depending on screw size)

- Shot Weight:

- Max Weight per Cycle: 1000 grams (dependent on material and configuration)

- Machine Type: Electric/Servo-hydraulic Hybrid

- Controller Type: DCS PLC

- Control System: Advanced Integrated DCS PLC Control with touchscreen interface

- Cycle Time: 6-15 seconds (depending on material and mold complexity)

- Molding Surface Area: 2000 x 2000 mm (max mold size)

- Machine Dimensions: Approximately 7.5m x 2.5m x 2.5m (L x W x H)

- Power Supply: AC 380V, 50Hz, 3-phase

- Cooling System: Air and Water-cooled with temperature regulation

- Machine Weight: Approx. 25,000 kg

Product Specifications:

-

Injection Unit Specifications:

- Screw Design: High-precision multi-stage screw, ideal for handling a variety of materials including PE, PP, PS, ABS, PC, and engineering plastics.

- Injection Rate: Up to 350 grams/sec, allowing for fast and efficient plastic injection into molds.

- Barrel Heating: Equipped with electrical heaters and cooling channels to precisely control the material temperature.

-

Clamping Unit:

- Clamping Force: The 550-ton clamping unit ensures uniform pressure distribution across the mold for perfect part formation.

- Tie Bar Distance: 570 x 570 mm for large mold support.

- Mold Height Adjustment: Automatic mold height adjustment to accommodate different mold sizes and optimize cycle time.

- Ejection System: Equipped with hydraulic ejection, allowing for fast and precise removal of molded parts.

-

DCS PLC Control System:

- Real-time Control: Provides real-time feedback from the injection molding machine, controlling the entire cycle from injection to ejection.

- Multi-axis Control: Controls key functions such as the injection screw, hydraulic movements, and clamping pressure.

- Advanced Diagnostics: Continuous monitoring of machine health, sensor diagnostics, and error codes to prevent faults and reduce downtime.

- Touchscreen Interface: User-friendly HMI (Human-Machine Interface) for easy operation and visualization of the injection molding process.

- Energy Efficiency Control: The servo-hydraulic system allows for optimal energy use based on the load, improving overall machine efficiency.

-

Hydraulic System:

- Servo Motor Pump Drive: The machine is equipped with an energy-efficient servo motor drive that adjusts the pump pressure to meet the real-time demand of the mold cycle, ensuring reduced power consumption.

- High-Pressure Hydraulic System: Operating at pressures of up to 300 bar, ensuring fast clamping, ejection, and injection cycles.

-

Molding Process:

- Injection Process: The DCS PLC allows precise control of injection speed, pressure and temperature, ensuring the highest quality moldings.

- Cooling Control: The system manages cooling time and temperature control to optimize cycle times and part quality.

- Sequential Injection: Multiple injection phases can be programmed for complex molding operations, improving the molding of parts with varied geometries.

-

Material Compatibility:

- Supports a wide range of thermoplastic materials, such as standard plastics (PE, PP, PS, ABS) and engineering resins (PC, PA, POM).

- Material Feeding System: Includes a high-efficiency hopper loader to minimize material waste.

-

Energy Efficiency:

- Servo-driven hydraulic system reduces energy consumption by optimizing the operation of the hydraulic pump based on demand.

- Energy-saving modes reduce power usage during idle times and optimize cycle times.

-

Safety Features:

- Safety interlocks to prevent unauthorized access to the machine during operation.

- Emergency stop system integrated with the DCS to immediately halt the machine in case of faults or emergency situations.

- Overload protection to prevent excessive pressure or mechanical damage.

Key Features:

- 550 Ton Clamping Force: Ideal for molding large, high-precision parts in industries like automotive and electronics.

- High-Speed Injection: Capable of rapid injection cycles to improve productivity.

- Energy-Efficient Servo-Hydraulic System: Reduces power consumption while providing precise control of molding processes.

- Advanced DCS PLC Control: Integrated, real-time control for every aspect of the injection molding process, improving accuracy and reducing errors.

- User-Friendly Touchscreen Interface: Easy-to-use interface for machine operation and troubleshooting.

- Precise Temperature and Pressure Control: Ensures high-quality molding results, minimizing scrap and maximizing yield.

- Flexible Mold Support: Accommodates a wide range of mold sizes, providing flexibility in production.

- Reduced Downtime: Advanced diagnostics and error prevention systems for minimal machine downtime.

Applications:

The Borche 550 Ton Injection Molding Machine is widely used in industries that require high precision and large-volume production, including:

-

Automotive Industry:

- Manufacturing automotive components, such as bumpers, dashboard parts, and interior components.

- Ideal for producing high-strength plastic parts with precise tolerances.

-

Consumer Electronics:

- Production of electronic enclosures, smartphone housings, and connector components.

- Offers excellent part detail and surface finish, critical for electronic products.

-

Medical Devices:

- Used in the production of medical equipment, such as syringes, medical connectors, and plastic housings for medical instruments.

- Ensures high-precision molding to meet regulatory standards.

-

Packaging Industry:

- Produces plastic containers, caps, bottles, and food packaging components.

- Provides fast cycle times and consistency, ideal for large-volume packaging runs.

-

Consumer Goods:

- Manufacturing of household products, such as plastic containers, toys, and appliances.

- Offers high-speed production and flexibility in part design.

Conclusion:

The Borche 550 Ton Injection Molding Machine (2013 Model, 19109-168) with a DCS PLC Module is a versatile and high-performance solution for large-scale injection molding applications. The advanced control system, high clamping force, energy-efficient servo-hydraulic technology, and user-friendly interface make it suitable for a wide range of industries, ensuring high-quality production, precision control, and enhanced efficiency. With its robust diagnostics and real-time monitoring capabilities, this machine is built for high productivity and minimal downtime, making it an ideal choice for modern manufacturing needs.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922