الوصف

Product Name:

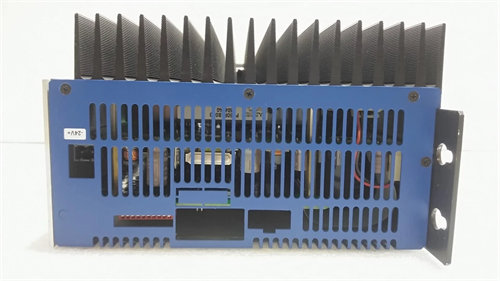

KOLLMORGEN CP320260 DCS/PLC Module

Product Description:

The KOLLMORGEN CP320260 is a Distributed Control System (DCS) / Programmable Logic Controller (PLC) module designed to provide reliable control and automation solutions for a wide range of industrial applications. Part of the Kollmorgen Automation Systems, this module is engineered to offer exceptional flexibility, high performance, and precise control for complex processes. The CP320260 is ideal for industries that require real-time process monitoring, integration of multiple control systems, and high levels of automation.

This module supports a range of industrial protocols, providing seamless communication with field devices and other control systems. Its modular design enables scalability, making it suitable for a variety of applications, from small control systems to large-scale industrial automation projects. With features that include real-time data processing, robust diagnostics, and high reliability, the CP320260 ensures optimized performance in mission-critical environments.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) module

- Manufacturer: Kollmorgen

- Series: Part of Kollmorgen’s Automation Systems for real-time industrial control.

Input/Output Specifications:

- Digital Inputs: The CP320260 supports digital inputs for discrete field devices, such as sensors, switches, and relays.

- Digital Outputs: Supports digital outputs to control actuators, relays, and valves, enabling efficient control of automation equipment.

- Analog Inputs: Includes analog inputs for continuous measurements like temperature, pressure, and flow rates.

- Analog Outputs: Provides analog outputs to control devices such as variable-speed drives, actuators, and controllers requiring precise analog signals.

Communication Protocols:

- Modbus RTU/TCP: Supports Modbus RTU and Modbus TCP communication protocols, allowing integration with a wide variety of field devices and systems.

- Profibus DP: Offers integration with Profibus DP-enabled devices for high-speed, reliable communication.

- Ethernet/IP: Supports Ethernet/IP for real-time communication in Ethernet-based networks, ensuring fast data transfer and control.

- CANopen: Compatible with CANopen protocol for network communication with devices like motors, drives, and sensors.

Power Supply:

- Operating Voltage: Typically operates at 24 V DC or 48 V DC, depending on the specific configuration.

- Power Consumption: Varies based on the configuration and connected field devices, but generally low for energy-efficient operation.

Control and Performance:

- Real-Time Control: Designed for real-time control, ensuring fast, accurate response to dynamic changes in the process.

- Data Processing: Supports high-performance data processing capabilities to ensure rapid and efficient control, especially in time-sensitive processes.

- Response Time: Optimized for low-latency responses, ensuring precise control of complex systems.

Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F), making it suitable for a variety of industrial environments.

- Storage Temperature: Typically -40°C to 85°C (-40°F to 185°F), allowing for flexible storage conditions.

- Humidity: 5% to 95% RH, non-condensing.

- Vibration and Shock Resistance: Designed to meet industrial standards for shock and vibration, ensuring durability in harsh conditions.

Mounting and Integration:

- Mounting Type: Rack-mounted or installed within control panels, ensuring easy installation and integration with other control system components.

- Slot Configuration: Compatible with Kollmorgen’s modular control systems, providing flexibility to expand and adapt based on specific project needs.

Redundancy and Reliability:

- Redundant Power Supply Options: Supports redundant power configurations to ensure continued operation in case of power failure.

- Fail-Safe Operation: Features fail-safe functionality to guarantee system integrity in case of faults.

Safety and Compliance:

- Safety Features: Suitable for use in safety-critical applications where system integrity and uptime are crucial, such as in chemical plants, power plants, and oil & gas operations.

- Certifications: Compliant with major industry standards, including CE, UL, and ATEX, ensuring safety and reliability in hazardous environments.

Software and Programming:

- Kollmorgen Automation Studio: The CP320260 integrates with Kollmorgen’s Automation Studio, a powerful tool for system configuration, diagnostics, and programming. It allows users to easily configure the module, monitor the system, and perform real-time diagnostics.

- Programming Language: Typically supports IEC 61131-3 standard programming languages, such as Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST), providing flexibility for a wide range of automation needs.

Diagnostics and Monitoring:

- Built-In Diagnostics: Equipped with diagnostic LEDs and built-in diagnostic tools for monitoring the status and health of the system, ensuring quick identification and resolution of any issues.

- Alarms and Alerts: Capable of generating alarm notifications and alerts for operators, facilitating proactive troubleshooting and system maintenance.

Key Features & Benefits:

-

Modular Design:

- The CP320260 features a modular design, allowing for flexible integration and scaling of the control system based on the specific requirements of the application.

-

Real-Time Control:

- Offers real-time control capabilities, which is critical in industries such as power generation, process manufacturing, and water treatment, where timely responses and continuous monitoring are essential.

-

Advanced Communication:

- The module supports multiple communication protocols, including Modbus, Profibus, Ethernet/IP, and CANopen, ensuring compatibility with a wide range of field devices and other control systems.

-

Robust Environmental Performance:

- Built to withstand harsh industrial environments with features such as high shock and vibration resistance, as well as the ability to operate in extreme temperatures.

-

Reliability and Redundancy:

- Designed with redundant power options and fail-safe operation, ensuring reliable system performance even in mission-critical applications.

-

Comprehensive Diagnostics:

- Built-in diagnostics, including LED indicators, alarms, and alerts, to ensure easy troubleshooting and minimize downtime.

-

Safety Compliant:

- Meets stringent safety standards, making it suitable for use in hazardous and safety-critical applications.

Applications & Use Cases:

- Oil & Gas: For automation and monitoring of drilling rigs, refineries, and pipeline systems.

- Chemical Processing: Control of chemical reactions, batch processes, and continuous manufacturing.

- Power Generation: Control and monitoring of power plants, turbines, and electrical distribution systems.

- Water Treatment: For automation in water and wastewater treatment plants.

- Manufacturing: Managing complex production lines, robotics, and material handling systems.

Conclusion & Recommendation:

The KOLLMORGEN CP320260 DCS/PLC Module is a powerful and flexible automation solution designed for a wide variety of industrial applications. Its modular design, real-time control capabilities, and comprehensive diagnostics make it an excellent choice for systems that require high performance, reliability, and scalability. Whether in oil & gas, power generation, or chemical processing, the CP320260 ensures seamless integration and dependable operation, making it an ideal solution for industrial control systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922