الوصف

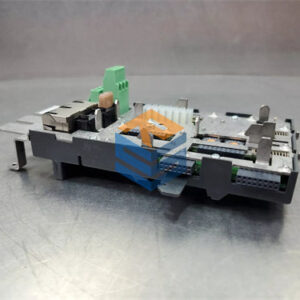

METSO D201463 DCS PLC Module

Product Name:

METSO D201463 DCS PLC Module

Product Description:

The METSO D201463 is part of Metso’s DCS (Distributed Control System) PLC (Programmable Logic Controller) modules, which are designed for process automation and control in industries that require high-precision monitoring and control systems. Metso’s DCS solutions are widely used in industries such as pulp and paper, mining, metal processing, energy, chemical, and oil and gas. The D201463 module is engineered to provide reliable and efficient control of complex industrial processes, enhancing automation and minimizing downtime in mission-critical operations.

This module is designed for integration into Metso’s DNA control system, which provides centralized process monitoring, alarm handling, data acquisition, and system diagnostics. The D201463 module is typically used for controlling and monitoring complex processes such as flow control, temperature regulation, pressure monitoring, and valve control within the larger industrial control systems.

Product Parameters and Specifications:

Model:

- METSO D201463

Type:

- DCS PLC Module for integration into the Metso DNA Control System

Manufacturer:

- Metso (now part of Valmet)

Key Features:

-

Highly Reliable: Designed for use in demanding industrial environments with long-term reliability and performance.

-

Modular Design: The D201463 module features a modular design, which allows for flexible expansion and scalability in large automation systems.

-

Real-Time Control: The module supports real-time control of industrial processes, including automation of various plant functions such as regulating flow rates, pressure, and temperature.

-

Integration: Seamless integration with the Metso DNA Control System allows for the creation of sophisticated control strategies, data acquisition, and detailed system diagnostics.

-

Advanced I/O Capabilities: The module supports a wide variety of digital and analog input and output channels, suitable for complex automation tasks.

-

Communication Protocols: Supports industrial communication protocols such as Modbus, Ethernet/IP, Profibus, and others to ensure interoperability with third-party devices and systems.

-

Data Logging: Capable of logging operational data for analysis, trend monitoring, and troubleshooting, improving operational efficiency.

-

Alarm Handling: Provides integrated alarm management, enabling timely responses to process deviations and enhancing system safety.

Specifications:

Inputs and Outputs:

- Digital Inputs: Typically 16, 32, or 64 channels depending on the module configuration.

- Digital Outputs: Configurable outputs for controlling relays, alarms, or process control equipment.

- Analog Inputs: Configurable for various sensor types such as temperature sensors (RTDs, thermocouples), pressure sensors, and flow meters.

- Analog Outputs: Provides analog signals to control actuators such as valves, motors, and pumps.

Input/Output Type:

- Analog I/O: 4-20 mA or 0-10 V (for standard industrial sensors).

- Digital I/O: 24 V DC, dry contact or TTL logic inputs and outputs.

Communication Protocols:

- Modbus RTU/TCP: For integrating with other devices or control systems.

- Ethernet/IP: Provides high-speed data transfer and networking capabilities for modern industrial environments.

- Profibus DP/PA: Used for connecting field devices like sensors, actuators, and PLCs in process control.

- HART: For connecting with field devices like smart sensors and valves that support the HART protocol.

Processing Speed:

- Real-time Processing: The module provides sub-millisecond response times, enabling quick adjustments and control actions based on real-time data.

Power Supply:

- 24 V DC (standard for industrial control systems).

Operating Temperature:

- -10°C to +60°C (ambient temperature range suitable for industrial environments).

Mounting:

- Rack-Mounted: Designed to be mounted in a standard 19-inch control cabinet or rack.

Dimensions:

- Height: Typically around 130 mm (depending on configuration).

- Width: 90 mm (for standard modules).

- Depth: Approximately 200 mm.

Environmental Protection:

- IP20 or higher rating depending on the specific version, designed to be mounted in a control panel or rack.

Key Advantages:

-

Flexibility: The module’s modular design allows for easy scaling and customization of the control system to meet specific process requirements.

-

Integration with Metso DNA: Tight integration with the Metso DNA Control System enhances overall plant performance by providing centralized control, data acquisition, and alarm management.

-

High Performance: The D201463 offers high-speed processing and response times, making it suitable for controlling high-precision and safety-critical processes in industries such as mining, paper production, and chemical manufacturing.

-

Ease of Use: The system’s user interface provides an intuitive and streamlined experience for operators, making it easier to monitor and control complex processes.

-

Enhanced Troubleshooting and Maintenance: The data logging and diagnostic capabilities of the D201463 module simplify troubleshooting and maintenance activities, ensuring high uptime and minimal disruptions.

-

Real-time Alarm and Event Handling: Integrated alarm management features ensure that operators can respond quickly to any system anomalies, improving safety and minimizing downtime.

Application Areas:

The METSO D201463 DCS PLC Module is used in a variety of industries and applications where process automation and control are essential, including:

-

Pulp and Paper Industry: For controlling papermaking processes, including controlling temperature, pressure, and flow in pulping and paper production lines.

-

Mining: Used in process automation for controlling crushers, conveyors, and flotation systems in mineral processing.

-

Metals and Steel Manufacturing: To automate processes such as rolling mills, furnace control, and material handling.

-

Chemical Processing: For process control in reactors, mixing, filtration, and distillation columns.

-

Power Generation: Used in power plants for controlling turbines, generators, and other critical power generation equipment.

-

Oil & Gas: Used in upstream and downstream processes for controlling pumps, compressors, and valves.

Conclusion:

The METSO D201463 DCS PLC Module is a versatile and high-performance component of the Metso DNA Control System. With its flexible I/O capabilities, fast processing speed, advanced communication protocols, and reliability, it is an ideal solution for industries that require precise control of complex processes. Whether used in mining, chemical, paper, or energy sectors, this module plays a crucial role in ensuring system efficiency, safety, and optimization.

1C31113G05 PLC

1C31113G06 PLC EMERSON

1C31116G01 EMERSON

1C31116G02 PLC EMERSON

1C31116G03 PLC EMERSON

1C31125G01 PLC EMERSON

1C31125G03 PLC EMERSON

1C31129G01 PLC

1C31129G02 PLC EMERSON

1C31129G04 EMERSON

1C31142G01 plc

1C31147G02

1C31150G01 EMERSON

1C31150G02 PLC EMERSON

1C31150G03 EMERSON

1C31157G01 PLC EMERSON

1C31157G02 EMERSON

1C31157G03 PLC

1C31161G02 PLC

1C31164G02 PLC

1C31169G01 PLC

1C31174G01 EMERSON

1C31174G02 PLC EMERSON

1C31174G03 PLC EMERSON

1C31174G04

1C31177G01 PLC

1C31177G02 PLC

EMERSON 1C31177G03

1C31179G01 PLC EMERSON

1C31179G02 EMERSON

1C31181G01 EMERSON

1C31181G02 PLC EMERSON

EMERSON 1C31181G03

1C31181G04 EMERSON

1C31189G01 EMERSON

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922