الوصف

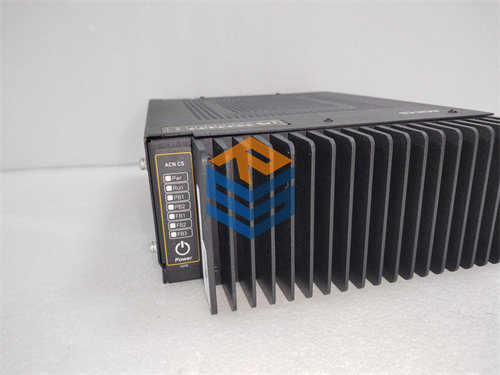

METSO D201925 PLC Module

Product Name:

METSO D201925 PLC Module

Product Description:

The METSO D201925 PLC Module is part of the Metso Automation family, which is renowned for its advanced process control solutions. This PLC module is designed for seamless integration into control systems, particularly in industries like mining, pulp and paper, energy, and chemical processing. It provides a reliable and flexible platform for automation tasks, ensuring smooth and efficient operation of complex industrial systems.

The D201925 is a high-performance module within Metso’s extensive range of process control products, offering robust features that enhance the accuracy and dependability of industrial operations. The module is known for its ability to handle demanding applications, support large-scale automation systems, and integrate seamlessly with various control protocols and hardware.

Key Features:

- Versatility: The D201925 is designed to be compatible with a wide variety of industrial processes, ensuring adaptability across different sectors.

- High Integration Capability: It can be integrated with different control systems, including distributed control systems (DCS) and programmable logic controllers (PLC), offering exceptional flexibility for automation tasks.

- Real-Time Monitoring and Control: Provides real-time data processing and control capabilities, ensuring optimal performance of equipment and processes.

- High Reliability: Built to withstand harsh industrial environments, ensuring a high level of operational continuity with minimal downtime.

- Scalability: It supports a modular design that allows for easy scaling up or down depending on the needs of the application.

- Energy Efficiency: Optimized for energy-efficient operation, reducing the operational costs associated with high power consumption.

Product Parameters:

- Input/Output Type: Supports digital and analog I/O modules for flexible connectivity with industrial sensors, actuators, and control devices.

- Communication Protocols: Supports common industrial communication protocols such as Modbus, Ethernet/IP, and Profibus, facilitating integration with other control systems and devices.

- Processor Speed: High-speed processing unit that can handle complex control tasks and real-time data analysis.

- Power Supply: Typically operates with a voltage range that suits most industrial environments (e.g., 24V DC or 48V DC, depending on the model).

- Environmental Tolerance: The module is designed to withstand extreme temperatures and industrial environmental conditions (e.g., dust, moisture, vibrations).

- Mounting: Typically DIN rail mounted for ease of installation in control panels and industrial cabinets.

- Diagnostics: Features built-in diagnostic capabilities to monitor performance, detect faults, and troubleshoot issues quickly.

- Software Integration: Compatible with Metso’s automation software for configuration, programming, and monitoring of the PLC system.

Specifications:

| Specification | Details |

|---|---|

| Model Number | D201925 |

| Brand | METSO |

| Type | PLC Module |

| Control System | Suitable for integration in Distributed Control Systems (DCS) and PLC systems |

| Input/Output | Digital and Analog I/O support |

| Communication Protocol | Modbus, Ethernet/IP, Profibus |

| Power Supply | Typically 24V DC or 48V DC |

| Mounting | DIN Rail Mounting |

| Environmental Range | Operating temperature range: -20°C to 60°C (dependent on model) |

| Processing Speed | High-performance, real-time processing |

| Diagnostics | Built-in diagnostic tools for fault detection and troubleshooting |

| Software Compatibility | Works with Metso’s proprietary automation software |

| Dimensions | Typically compact (dimensions depend on the exact module) |

| Certifications | CE, UL, RoHS (or specific certifications based on region) |

Applications:

- Mining Industry: Used for control of equipment in mining processes such as crushers, conveyors, and processing units.

- Pulp and Paper Industry: Enables control of paper machines, chemical dosing, and fluid handling systems.

- Energy and Power: Utilized for monitoring and controlling energy generation and distribution systems.

- Chemical Processing: Supports automation of chemical reactors, mixers, and material handling systems.

- Oil & Gas: Applicable for control of pumps, compressors, and drilling equipment.

Benefits:

- Reliability: Engineered for robust operation in tough industrial environments.

- Scalability: Easily scalable to meet the growing needs of production systems.

- Flexibility: Works with a wide range of communication protocols and integrates easily with other systems.

- Cost-Effectiveness: Designed for energy efficiency and minimized downtime, reducing overall operating costs.

Conclusion:

The METSO D201925 PLC Module is a powerful and versatile automation solution designed for large-scale industrial applications. It combines advanced processing capabilities with high integration flexibility, making it an ideal choice for companies looking to optimize their operations through reliable and efficient automation systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922