الوصف

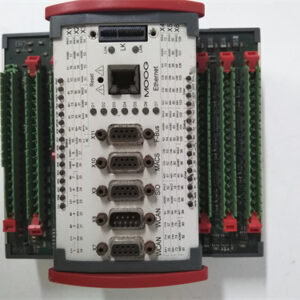

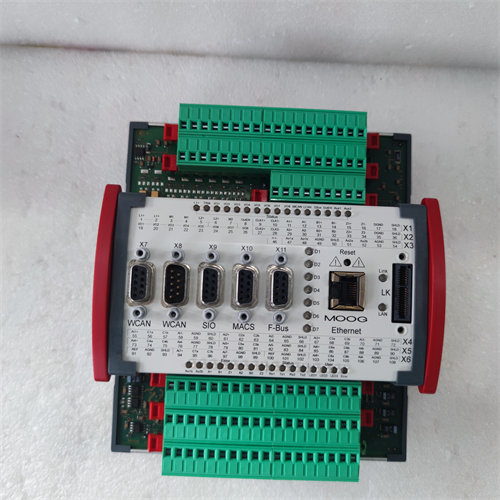

MOOG D136-001-001 DCS PLC Module

Product Name:

MOOG D136-001-001 – DCS PLC Module

Product Description:

The MOOG D136-001-001 is a sophisticated DCS (Distributed Control System) PLC Module designed for integration into industrial automation systems. MOOG, known for its high-precision motion control technologies, has extended its expertise to process automation by offering robust control solutions suitable for diverse industries like aerospace, automotive, robotics, energy, and manufacturing. The D136-001-001 module is engineered to provide high-performance control, real-time data processing, and robust communication for mission-critical industrial processes. It supports high-level diagnostics, safety, and scalability for complex and evolving industrial environments.

The D136-001-001 module is typically used in high-performance automation systems where precise and reliable control is essential. It is engineered to support a wide range of communication protocols, I/O configurations, and control strategies, allowing seamless integration into existing infrastructures. It is ideal for applications requiring real-time decision-making, such as manufacturing, power generation, aerospace systems, and industrial automation.

Product Parameters:

-

Model: MOOG D136-001-001

-

Type: DCS PLC Module

-

System Compatibility: Compatible with various DCS platforms, and can be integrated with MOOG’s proprietary control systems

-

Form Factor: Typically rack-mounted or modular depending on the system architecture

-

Power Supply:

- 24V DC (nominal)

- Power consumption: ~20W (can vary depending on configuration and usage)

-

Operating Temperature:

- Standard: -20°C to 60°C

- Storage Temperature: -40°C to 85°C

-

Relative Humidity: 5% to 95% (non-condensing)

-

Dimensions:

- Approximate dimensions: 4.5″ x 8″ x 2″ (can vary by configuration)

-

Weight: ~0.6 kg

Key Specifications:

-

Processor:

- High-performance microprocessor optimized for real-time control

- Supports multi-core processing for advanced control applications

- Low-latency response for critical process control tasks

-

Memory:

- RAM: 512MB to 1GB, depending on configuration

- Flash Memory: 2GB to 4GB for storing application programs, logs, and configuration files

- Expandable Memory: Modules available for memory expansion based on user requirements

-

Communication Protocols:

- Ethernet/IP: Provides high-speed, reliable communication with other systems and devices.

- Modbus TCP/IP: Supports integration with legacy devices and other automation systems.

- PROFIBUS/PROFINET: Flexible fieldbus protocol support for industrial devices.

- CANopen: For controlling CAN-based devices such as sensors, actuators, and more.

- HART: Communication protocol support for field devices with HART capabilities.

- Redundant Communication: Supports redundancy to ensure system reliability and failover in mission-critical applications.

- Serial Communication: Supports legacy serial protocols for backward compatibility with older systems.

-

I/O Capability:

- Digital I/O: Configurable up to 32 digital inputs and outputs per module (depends on specific system design).

- Analog I/O: Configurable up to 16 analog inputs and 8 analog outputs per module.

- Fieldbus I/O: Allows integration with PROFIBUS, Modbus, Foundation Fieldbus, and other fieldbus networks for scalable I/O integration.

- Expandable I/O: Modules can be expanded by adding additional I/O units depending on application needs.

-

Control Functions:

- Real-time Control: Supports real-time execution of advanced control algorithms like PID, adaptive control, and motion control.

- Multi-Tasking: Capable of running multiple control programs concurrently.

- Redundant Control: Allows for redundant control systems for enhanced reliability in critical processes.

- Fail-Safe Operation: Ensures system stability and continuous operation in case of faults or failures.

-

Safety Features:

- SIL 2/3 Compliance: Complies with Safety Integrity Level (SIL) 2 or 3 standards, making it suitable for safety-critical applications.

- Failover Mechanisms: Redundant hardware and software ensure failover in case of module failure.

- Emergency Shutdown (ESD): Can be integrated into safety systems to trigger emergency shutdown procedures when critical thresholds are met.

- Safety I/O Integration: Integrates safety I/O devices directly into the control loop for immediate action in case of hazards.

-

Diagnostics and Monitoring:

- Self-Diagnostics: Built-in self-diagnostic functions to detect issues early, enabling proactive maintenance.

- Status Monitoring: Continuous real-time monitoring of system status, I/O, communication health, and control loops.

- Event Logging: Logs important system events for future reference and troubleshooting.

- Predictive Maintenance: The module can provide early warning signals for potential failures, reducing unplanned downtime.

-

User Interface:

- MOOG Software Integration: Seamlessly integrates with MOOG’s proprietary software for intuitive control and monitoring.

- Web Access: Provides remote access for configuration, monitoring, and diagnostics via a web-based interface.

- Alarm Management: Supports advanced alarm management for monitoring and responding to critical conditions.

Key Features and Advantages:

-

High-Performance Control:

The D136-001-001 is built for high-performance, real-time control and decision-making. It supports complex algorithms and multi-tasking capabilities, making it ideal for demanding automation tasks. -

Flexible Communication:

It supports a wide range of communication protocols such as Ethernet/IP, PROFIBUS, Modbus TCP, and CANopen, making it highly flexible for integration into existing industrial networks. -

Safety-Critical Applications:

With SIL 2/3 compliance and built-in redundancy features, this module ensures high reliability and safety, especially in mission-critical operations such as aerospace, power generation, and automotive. -

Modular and Scalable:

The D136-001-001 is part of a modular system, enabling users to easily scale their system with additional I/O modules, processors, and communication modules. -

Real-Time Diagnostics and Monitoring:

The module includes extensive diagnostics capabilities that help with predictive maintenance and early failure detection, ensuring minimum downtime. -

Seamless Integration:

It integrates smoothly with MOOG’s control systems and software, ensuring a streamlined user experience for configuration, monitoring, and control. -

Redundant Architecture:

Redundant control systems and communication paths ensure that the D136-001-001 can handle the demands of high-availability systems. -

Compact and Efficient:

The module offers a compact design without sacrificing performance, making it ideal for space-constrained applications.

Applications:

The MOOG D136-001-001 DCS PLC module is ideal for industries requiring high-performance, safe, and reliable automation, such as:

- Aerospace: Flight control systems, avionics, and testing systems.

- Automotive: Robotics, manufacturing control, and testing.

- Energy: Power generation and distribution, particularly in renewable energy systems.

- Robotics: Advanced motion control and precision automation systems.

- Industrial Automation: High-precision control in manufacturing, process industries, and assembly lines.

Competitive Comparison:

Compared to similar PLC modules from manufacturers like Siemens, Rockwell Automation, or Schneider Electric, the MOOG D136-001-001 stands out due to:

- Advanced Control Algorithms: High-level control strategies, including real-time processing and adaptive control.

- Flexible Communication: Extensive protocol support for seamless integration into diverse industrial environments.

- Safety Compliance: SIL 2/3 certification for safety-critical applications, setting it apart for safety and reliability in critical systems.

- Motion Control Integration: MOOG’s heritage in motion control gives it an edge in applications requiring precision and high-speed control.

The MOOG D136-001-001 DCS PLC module is a versatile, high-performance controller suitable for industries requiring real-time data processing, high precision, and robust safety features. With flexible communication protocols and extensive diagnostic capabilities, it supports scalable, mission-critical automation systems in industries like aerospace, automotive, energy, and industrial automation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922