الوصف

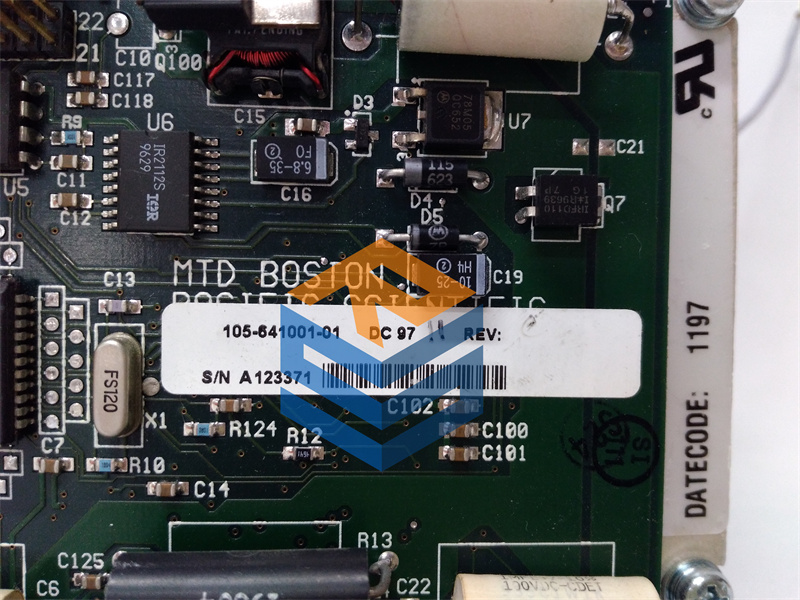

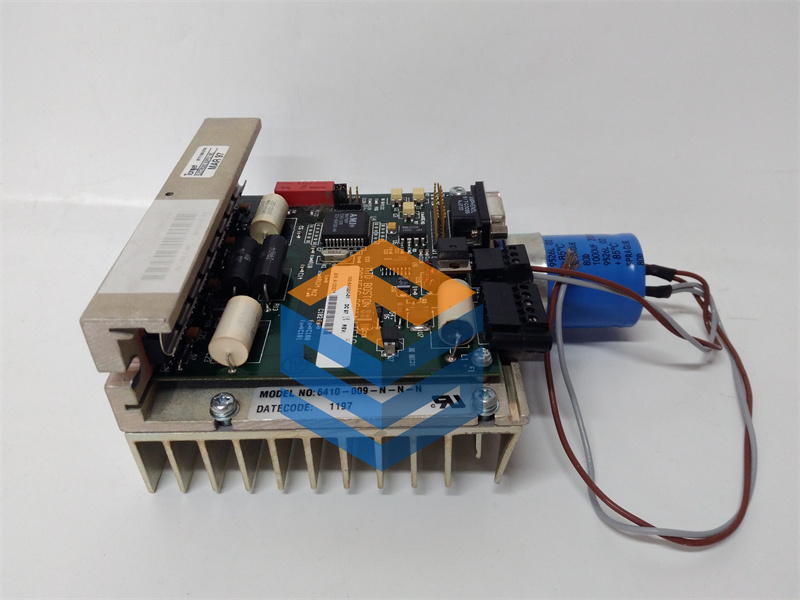

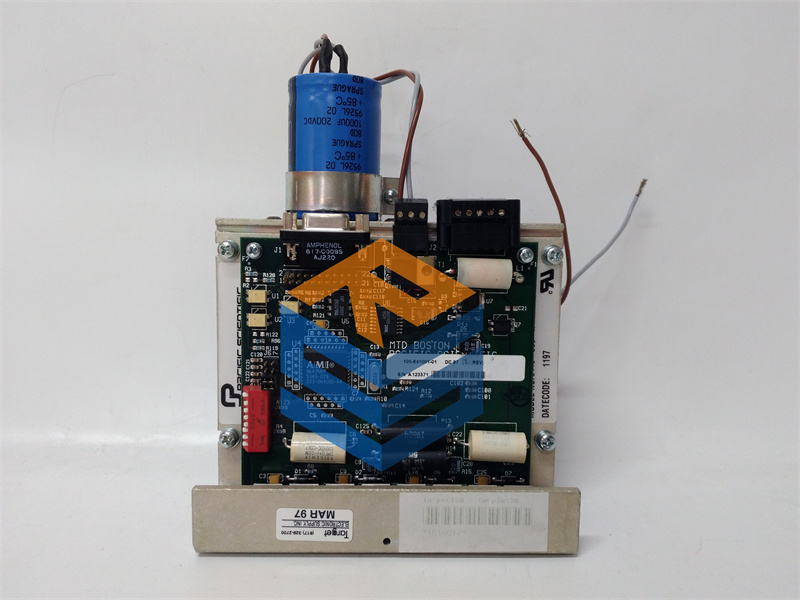

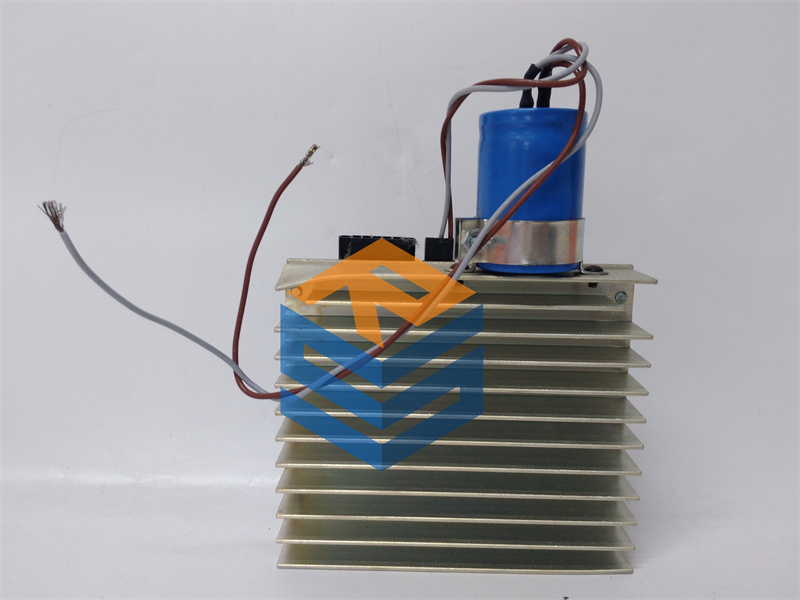

The PACIFIC 6410-009-N-N-N is a Stepper Drive from the Pacific Scientific (now part of Kollmorgen / Danaher Motion) 6410 Series. This module is a crucial component in motion control systems, specifically designed to control two-phase stepper motors.

The “6410” denotes the series, and the “-009” likely indicates a specific power level or configuration within that series. The “-N-N-N” suffix typically refers to options like “No Cover,” “No Heat Sink,” and “No Connector Kit,” indicating a basic, unaccessorized version of the drive.

This stepper drive converts step and direction inputs, typically from a motion controller or PLC, into precisely regulated motor winding currents, allowing for accurate position and speed control of a stepper motor.

Part One: Optimized SEO Titles

- PACIFIC 6410-009-N-N-N: Stepper Drive for 2-Phase Motors

- 6410-009-N-N-N Pacific Scientific: High-Performance Stepper Motor Driver

- Kollmorgen 6410-009-N-N-N: Microstepping Stepper Drive

- Buy 6410-009-N-N-N: Genuine Pacific Scientific Motion Control

- 6410-009-N-N-N for Sale: Precision Stepper Motor Control

- PACIFIC 6410-009-N-N-N: Industrial Motion Control Solution

- Stepper Motor Controller 6410-009-N-N-N: For Automation & Robotics

- 6410-009-N-N-N Drive: Enhancing Stepper System Resolution

- PACIFIC 6410-009-N-N-N: Features Digital Electronic Damping

- 6410-009-N-N-N Stepper Drive: Compact & Efficient Motion

Part Two: Brief Product Description

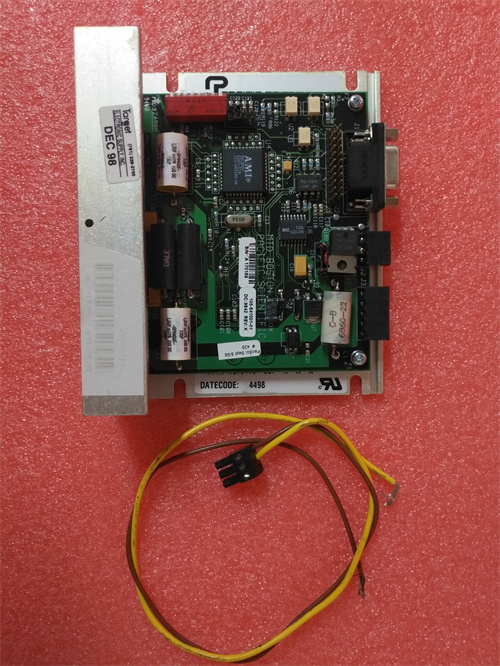

The PACIFIC 6410-009-N-N-N is a Stepper Drive from the Pacific Scientific 6410 Series. It’s designed to precisely control two-phase stepper motors by converting step and direction input signals into regulated motor winding currents. Key features include microstepping capabilities for smooth, high-resolution operation, mid-band instability compensation, bipolar chopping, and integrated fault protection. With a power level of 7.1 A peak / 5 A RMS and a 24-75 Vdc input, this compact drive is widely used in applications requiring accurate and reliable motion control.

- Product Type: Stepper Drive / Motor Controller

- Manufacturer: Pacific Scientific (now part of Kollmorgen / Danaher Motion)

- Model/Part Number: 6410-009-N-N-N

- Function: Controls 2-phase stepper motors based on step and direction inputs.

- Key Features: Microstepping, mid-band instability compensation, fault protection.

Part Three: Detailed Product Description

Have you ever witnessed the precise, intricate movements of a 3D printer head, a robotic arm assembling micro-components, or a CNC machine carving complex shapes? These applications rely heavily on stepper motors for their accurate open-loop positioning. However, stepper motors themselves need a sophisticated “conductor” to translate digital commands into smooth, powerful motion. This is precisely the role of the PACIFIC 6410-009-N-N-N Stepper Drive. It’s the intelligent interface that takes basic step and direction signals and transforms them into the complex current waveforms needed to make a stepper motor perform with high resolution and minimal vibration.

I once worked on a packaging machine where the existing stepper drives were causing noticeable vibrations at certain speeds, leading to inconsistent product placement and packaging defects. The older drives lacked advanced damping features. We upgraded to the Pacific Scientific 6410 series, including units like the 6410-009-N-N-N. The difference was immediate and dramatic. The machine ran significantly smoother, especially through the critical mid-speed ranges, thanks to the drive’s microstepping and digital electronic damping features. This directly translated into higher packaging accuracy, reduced product damage, and increased throughput – a clear testament to the impact of high-quality motion control components.

Precision Motion through Advanced Control: The PACIFIC 6410-009-N-N-N is a microstepping stepper drive that uses a 4-phase bipolar chopping technique. Here’s what that means for performance:

- Microstepping: Instead of moving in full steps, the drive can divide each full step into many smaller “microsteps.” This significantly increases the motor’s resolution (up to 50,000 steps per revolution for 1.8° motors) and results in much smoother, quieter operation, especially at low speeds, eliminating audible noise and resonance.

- Mid-Band Instability Compensation (Digital Electronic Damping™): Stepper motors are prone to resonance and instability in certain mid-speed ranges. This drive incorporates patented technology to actively damp these oscillations, ensuring that the motor maintains full torque and operates smoothly across its entire speed range. This is critical for high-performance applications.

- Bipolar Chopping: This advanced current control method ensures that the motor winding currents are precisely regulated at a high frequency (e.g., 20 kHz). This leads to lower ripple current, reduced heat dissipation in the motor, and improved current control, even during dynamic braking.

Robust and Feature-Rich for Industrial Use: This stepper drive is designed for reliable operation in demanding industrial environments:

- Power Level: The 6410-009-N-N-N handles a power level of 7.1 A peak, 5 A RMS, with a supply voltage range of 24-75 VDC. The output current is dip switch selectable, typically from 0.625 A to 5 A RMS, providing flexibility for various motor sizes.

- Fault Protection: It includes built-in protection against common issues like line-to-line and line-to-neutral shorts, internal power supply under-voltage, and bus overvoltage, protecting both the drive and the motor.

- Compact Size: Its small footprint (e.g., 1.5” W x 5” H x 4.3” D) means it requires minimal panel space, making it suitable for compact machine designs.

- Idle Current Reduction: This feature automatically reduces the motor winding current by 50% during idle periods (when no step commands are received), minimizing motor heating and energy consumption.

- Optically Isolated Signal Interface: The signal input interface is optically isolated, which is crucial for preventing electrical noise from the control system or power supply from affecting the sensitive motor control signals.

Technical Specifications (Confirmed from product documentation):

Key Applications:

The PACIFIC 6410-009-N-N-N is a versatile stepper drive suitable for a wide array of industrial automation tasks demanding precise and smooth motion control:

- X-Y Tables and Gantry Systems: For precise positioning in laser cutting, dispensing, 3D printing, and pick-and-place applications.

- Packaging Machinery: Controlling indexing, filling, sealing, and labeling mechanisms.

- Robotics (specific types): For certain axes or auxiliary movements where stepper motors are preferred for their cost-effectiveness and open-loop control.

- Specialty Machinery: Custom-built equipment requiring accurate material indexing, feeding, or tool positioning.

- Labeling Machines: Ensuring precise label application.

- Textile Machinery: Controlling fabric feed and tool movements.

- CNC Machining Centers (for auxiliary axes): Where high precision and smooth movement are critical.

Related Products:

To implement a complete motion control system with the PACIFIC 6410-009-N-N-N Stepper Drive, you would typically use it with:

- 2-Phase Stepper Motors: Specifically designed by Pacific Scientific/Kollmorgen to work optimally with their drives.

- Motion Controller/Indexer: A separate device (e.g., a PLC with motion control capabilities, a dedicated motion controller) that generates the step and direction pulses for the drive.

- DC Power Supply: A single, regulated DC power supply (24-75 VDC) to power the drive.

- Twisted and Shielded Cabling: Recommended for power and signal cables to reduce electrical noise.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922