الوصف

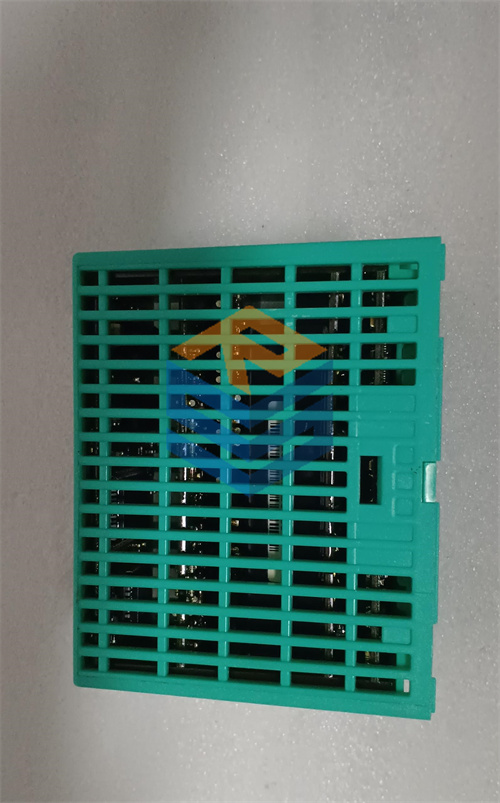

The Pepperl+Fuchs RSD-FI-Ex2 is a 2-channel frequency input module that’s intrinsically safe. It is designed to be a part of a remote I/O system, allowing for the safe and reliable measurement of frequencies and pulse rates from field devices located in hazardous environments. This module is essential for applications requiring precise monitoring of rotational speed, flow, or pulse signals.

Technical Breakdown 🛠️

The model number for this module breaks down to reveal its key functions and safety features:

- RSD (Remote System Digital): This indicates the module is part of Pepperl+Fuchs’s modular remote I/O family. These systems allow you to connect a wide variety of sensors and actuators in hazardous areas (like Zone 1 or Zone 2) to a central control system (PLC or DCS) in a safe area, simplifying wiring and reducing costs.

- FI (Frequency Input): This is the module’s core function. It’s specifically designed to read and process high-speed digital signals. The module can be configured for a variety of tasks, including:

- Frequency measurement: Measures the number of cycles per second (Hz).

- Pulse rate measurement: Counts individual pulses.

- Rotational speed monitoring: Connects to devices like proximity sensors to measure rotations per minute (RPM).

- Flow measurement: Reads pulses from a flow meter to calculate flow rate.

- Ex2 (Explosion Protection): The “Ex” designation confirms that the module is certified for use in hazardous areas. It achieves this through intrinsic safety, a protection technique that limits the electrical and thermal energy of the circuit to a level too low to ignite a flammable mixture of gas, vapor, or dust. This allows for safe operation and even live maintenance (hot-swapping) in explosive environments. The “2” signifies it’s a specific version of the module.

This module acts as a critical interface, taking fast-changing signals from the field and converting them into reliable, safe data that can be used by the control system to ensure the safety and efficiency of the plant.

Typical Applications 🏭

- Oil & Gas: Monitoring the rotational speed of pumps and motors or the flow rate of fluids in pipelines.

- Chemical Industry: Measuring flow in reactors and tanks where flammable materials are present.

- Wastewater Treatment: Counting pulses from flow meters in areas where methane gas may accumulate.

- Pharmaceutical Manufacturing: Monitoring the speed of mixers or blenders in environments with explosive dusts.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922