الوصف

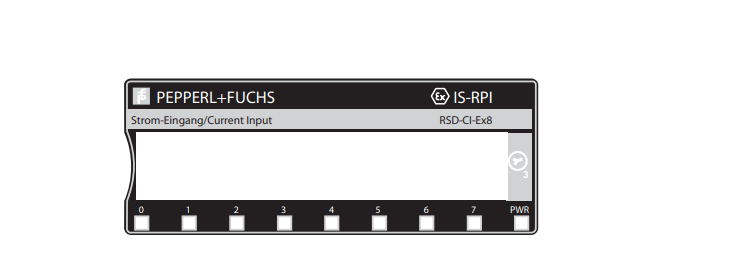

PEPPERL+FUCHS RSD-TI-EX8

The Pepperl+Fuchs RSD-TI-EX8 is an 8-channel, intrinsically safe temperature input module designed for use in hazardous industrial environments. It’s a key component of a remote I/O system, enabling the safe and reliable acquisition of temperature data from sensors located in potentially explosive atmospheres.

Key Features and Functionality 💡

This module’s model number breaks down to reveal its precise function:

- RSD (Remote System Digital): This indicates the module is part of Pepperl+Fuchs’ modular remote I/O family. This system allows you to install the module in a Zone 1 hazardous area, while its connected sensors can be in a Zone 0 area, providing a flexible and safe way to collect data from remote locations.

- TI (Temperature Input): The core function of this module is to read temperature signals. It is highly versatile, supporting a wide range of common industrial temperature sensors, including:

- Thermocouples (T/C): Types B, E, J, K, L, N, R, S, T.

- Resistance Temperature Detectors (RTDs): 2-, 3-, and 4-wire configurations of Pt100, Ni100, and others.

- mV and Resistance Inputs.

- EX (Explosion Protection): This is the module’s most critical feature. The “Ex” designation signifies that it is certified for use in hazardous areas. It achieves this through intrinsic safety, a protection technique that limits the electrical and thermal energy of the circuit to a level too low to ignite a flammable mixture of gas, vapor, or dust. This allows for safe, live maintenance and a significant reduction in the cost and complexity associated with explosion-proof enclosures.

- 8 (8 Channels): The module has eight independent input channels, allowing a single device to monitor up to eight different temperature points simultaneously. This high-density design saves valuable cabinet space and reduces system complexity and cost.

In a power plant, refinery, or chemical facility, this module serves as a critical interface, converting analog sensor signals from the field into a digital format that the main control system can process, all while maintaining the highest level of safety.

Typical Applications 🏭

- Oil & Gas: Monitoring process temperatures in refineries, pipelines, and offshore platforms where flammable hydrocarbons are present.

- Chemical Industry: Ensuring precise temperature control for reactors and tanks containing hazardous chemicals.

- Pharmaceuticals: Maintaining a safe and controlled environment during the production of drugs where explosive solvents may be used.

- Power Generation: Temperature monitoring in areas with flammable gases or dust, such as near boilers or fuel systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922