الوصف

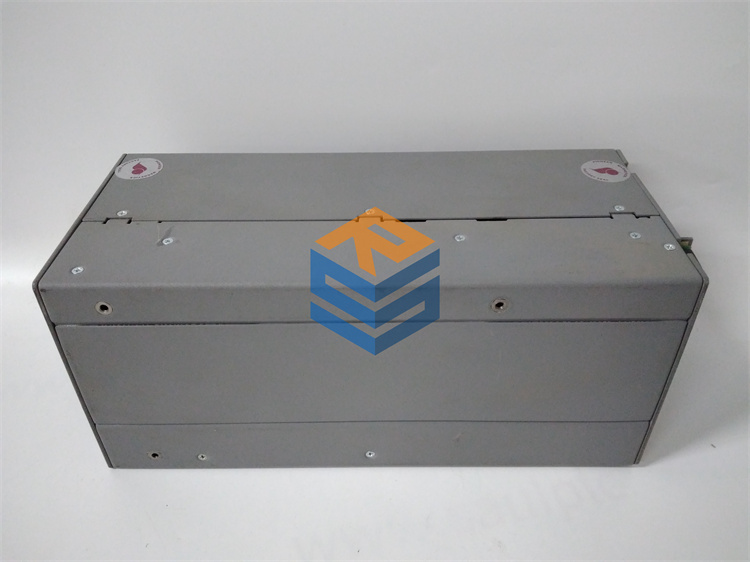

PIONEER MAGNETICS PM3398BP-6-1-3-E DCS PLC Module

Product Name:

- PIONEER MAGNETICS PM3398BP-6-1-3-E

- Type: DCS PLC Module

- Series: PM3398BP

Product Description:

The PIONEER MAGNETICS PM3398BP-6-1-3-E is a highly advanced Distributed Control System (DCS) PLC module designed for integration into large-scale automation systems. It is engineered to provide reliable control and monitoring of industrial processes in sectors such as manufacturing, power generation, petrochemical plants, and more. The module is built for high-performance applications where precision control and real-time data processing are essential.

Key features of the PM3398BP-6-1-3-E include redundancy support, flexible I/O configurations, real-time monitoring, and robust communication capabilities. This PLC module is designed to improve the safety and efficiency of automated systems by offering superior control, diagnostics, and fault-tolerant capabilities.

Product Parameters & Specifications:

General Information:

- Module Type: DCS PLC (Programmable Logic Controller) module for industrial automation systems.

- Model: PM3398BP-6-1-3-E

- Application Areas: Widely used in industrial processes such as manufacturing, power generation, oil and gas, chemical processing, water treatment, and more.

- Manufacturer: Pioneer Magnetics, a leading brand in industrial control systems.

Electrical Specifications:

- Input Voltage: Typically 24V DC, ideal for integration into standard industrial control systems.

- Power Consumption: Around 10-25W depending on configuration and system load.

- Current Consumption: <1.5A at 24V DC under normal operational conditions.

- Redundant Power Supply: Supports dual power supply configurations to ensure continuous operation in case of power failures.

I/O Configuration:

- Digital I/O: The module supports a wide range of digital inputs and outputs, commonly used for controlling relays, switches, and other digital devices in automation systems.

- Analog I/O: It offers analog I/O channels with 4-20mA or 0-10V signals for more precise control of temperature, pressure, flow, and other critical process parameters.

- High-Speed I/O: Includes high-speed input/output options for time-sensitive applications requiring fast data acquisition and response.

Communication Protocols:

- Fieldbus Communication: The module supports various industrial protocols such as Modbus, Profibus, and Ethernet/IP for seamless integration with field devices and other control systems.

- Redundant Communication: Built-in support for redundant communication pathways to ensure continuous data transfer and system operation.

- Ethernet Ports: High-speed Ethernet ports enable reliable communication over networks, allowing for remote monitoring and control.

Processor & Performance:

- Processor Type: High-performance 32-bit processor for real-time control tasks and data processing.

- Real-Time Control: Real-time execution of control algorithms, essential for industries requiring instant responses, such as manufacturing automation and power plant operations.

- Memory Capacity: Offers sufficient memory to handle complex programs and large amounts of data, allowing for sophisticated control tasks in large-scale industrial applications.

Environmental Specifications:

- Operating Temperature: 0°C to 55°C (32°F to 131°F), making it suitable for most industrial environments.

- Storage Temperature: -20°C to 70°C (-4°F to 158°F).

- Humidity: Can operate in environments with 5% to 95% non-condensing humidity.

- Vibration and Shock Resistance: Designed to meet industrial standards for vibration and shock, ensuring reliability even in harsh conditions.

Physical Specifications:

- Dimensions: Typically 3U or 6U depending on the configuration (standard for rack-mounted industrial modules).

- Weight: Around 1.5-2 kg (3.3-4.4 lbs), depending on the configuration.

- Mounting: Designed for rack mounting, commonly used in 19-inch industrial racks.

- Enclosure Rating: IP20 rated for protection against dust and accidental contact with live parts.

Software and Programming:

- Programming Environment: Compatible with industrial programming tools such as Ladder Logic, Structured Text, and Function Block Diagram (FBD). It is suitable for integration with Pioneer Magnetics’ proprietary software.

- Simulation and Testing: Includes diagnostic and testing tools for program simulation, allowing users to verify and validate control logic before deployment.

- Diagnostic Tools: Offers a set of real-time diagnostic tools to monitor system health, detect failures, and minimize downtime during operation.

Redundancy and Fault Tolerance:

- Redundant Power Supply: Designed to support dual power supply configurations for critical redundancy.

- Redundant Communication Paths: Supports redundant communication protocols to maintain operational continuity even if one communication path fails.

- Hot Standby Configuration: Allows for hot standby redundancy, ensuring that another module is ready to take over instantly if the active module fails.

- Self-Diagnostics: Includes advanced self-diagnostics to continuously monitor system health, automatically detect faults, and trigger corrective actions.

Key Features & Benefits:

- Real-Time Control: Capable of real-time processing, ideal for industries that require precise and immediate control over automated processes.

- High Availability: Built-in redundancy features, including dual power supplies and communication paths, ensure system availability and reliability in critical environments.

- Flexibility: Supports a wide range of I/O options, communication protocols, and system configurations, allowing the module to fit into diverse industrial applications.

- Ease of Integration: Supports standard industrial protocols (Modbus, Profibus, etc.), making it easy to integrate into existing automation and control systems.

- Scalability: Modular design enables scalability, allowing the system to grow as industrial requirements evolve.

- Fault Detection & Isolation: Built-in diagnostics and fault isolation features improve system uptime by detecting issues early and minimizing the impact of faults.

Applications:

- Power Generation: Used for controlling critical operations in both traditional and renewable energy power plants.

- Chemical & Petrochemical: Provides robust process control in refineries, chemical plants, and oil extraction operations.

- Water Treatment: Controls and monitors water treatment plants, ensuring compliance with environmental standards.

- Manufacturing: Integrated into automated manufacturing lines for precise control of assembly processes, product quality, and system efficiency.

Conclusion:

The PIONEER MAGNETICS PM3398BP-6-1-3-E DCS PLC Module is a high-performance, fault-tolerant control solution designed for mission-critical applications in industries such as power generation, chemical processing, and manufacturing automation. With real-time control capabilities, redundancy support, and flexible I/O configurations, this module ensures high reliability and performance, making it an ideal choice for systems where continuous operation and precise control are vital.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922