الوصف

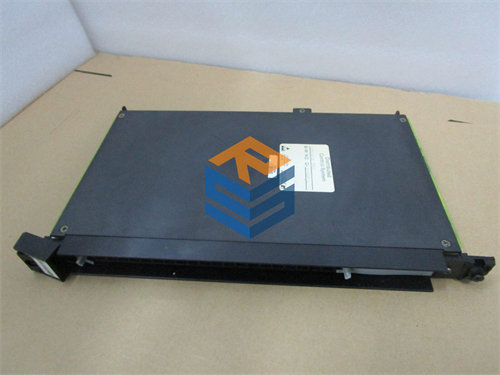

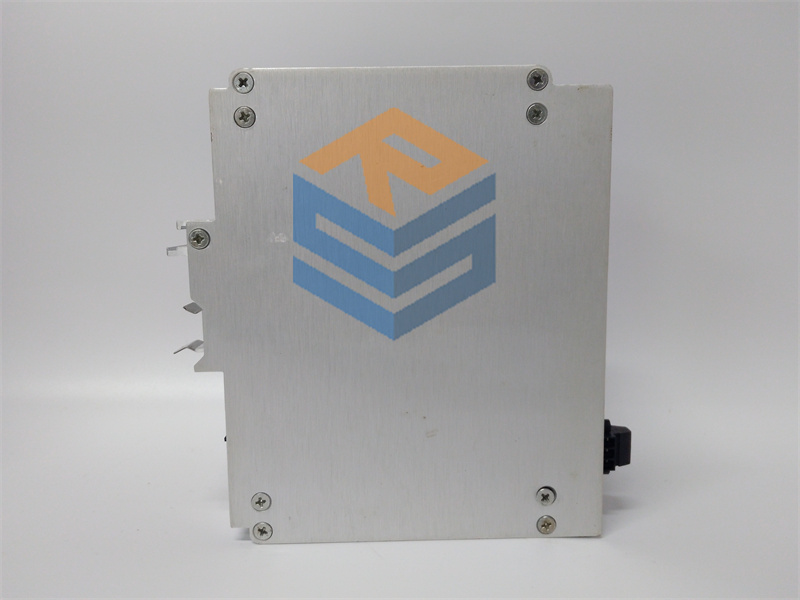

Product Name:

RELIANCE MC-D5006-A DCS PLC Module

Product Description:

The RELIANCE MC-D5006-A is a Distributed Control System (DCS) or Programmable Logic Controller (PLC) module, designed for high-performance control and automation tasks within industrial settings. It is part of the Reliance Electric automation platform, used in sectors such as oil and gas, chemical, power generation, water treatment, and manufacturing.

The MC-D5006-A module acts as a central processor, responsible for executing control algorithms, processing input and output signals, managing communication with field devices, and ensuring reliable and safe operation of industrial systems. It supports redundancy configurations, offering high availability and continuous operation even in critical processes. This module provides flexible integration with other control and monitoring equipment, making it suitable for complex industrial automation applications.

Product Parameters & Specifications:

Module Type:

- Type: Distributed Control System (DCS) CPU Module / Programmable Logic Controller (PLC) Module

- Manufacturer: Reliance Electric

- Model/Part Number: MC-D5006-A

- Series: MC Series DCS

Control & Processing:

- Processor Type: High-performance processor for control, monitoring, and data processing tasks.

- Processing Power: Designed to handle complex control algorithms and large-scale automation systems with quick response times.

- Real-Time Processing: Provides real-time control and monitoring for industrial applications, ensuring fast response to system changes and operational adjustments.

Input/Output Configuration:

- Digital Inputs (DI): Configurable digital inputs for a wide range of sensors and devices.

- Digital Outputs (DO): Digital outputs to control devices like relays, valves, or other actuators.

- Analog Inputs (AI): Capable of handling analog signals from sensors measuring variables such as temperature, pressure, flow, and level.

- Analog Outputs (AO): Outputs control signals to analog devices like valves, variable-speed drives, or other controllers.

- Expandable I/O: Offers scalability for adding more I/O modules as needed for larger systems.

Communication Protocols:

- Ethernet/IP: High-speed communication over Ethernet networks, enabling fast data exchange between system components.

- Modbus TCP/IP: Support for Modbus TCP, allowing seamless integration with other devices and systems supporting this protocol.

- Profibus DP/PA: Provides Profibus support for connecting field devices and other control systems in process automation.

- Serial Communication: Supports serial communication for connecting legacy devices or systems.

Redundancy & Reliability:

- Redundant Power Supplies: Supports redundant power supplies to ensure the system remains operational in case of a power failure.

- System Redundancy: Allows for redundant processors and I/O modules to ensure high availability and fault tolerance.

- Hot Swappable: Components such as power supplies and communication modules are hot-swappable for maintenance without system downtime.

- Diagnostic Features: Includes built-in diagnostics to monitor system health, detect faults, and prevent system failures.

Power Supply:

- Operating Voltage: 24V DC or 48V DC depending on system configuration.

- Power Consumption: Low power consumption designed to operate efficiently in large-scale industrial applications.

- Back-Up Power: Optional battery backup or UPS support for maintaining control during power outages.

Environmental Specifications:

- Operating Temperature: Typically ranges from 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -20°C to +70°C (-4°F to +158°F), suitable for storage in harsh industrial environments.

- Humidity: Capable of operating in a range of 5% to 95% relative humidity (non-condensing).

- Vibration Resistance: Designed for operation in environments with significant vibrations, such as factories or manufacturing plants.

Safety & Compliance:

- SIL Compliance: Designed to meet Safety Integrity Level (SIL) standards for safety-critical applications.

- Standards Compliance: Meets industry standards such as CE, UL, and CSA for safety and operational reliability.

- Functional Safety: Compliant with functional safety standards like IEC 61508 for applications requiring high levels of safety.

Software & Programming:

- Software Compatibility: Works seamlessly with Reliance Electric automation software, providing configuration, control, and diagnostics functionalities.

- Programming Languages: Supports standard programming languages like Ladder Logic, Structured Text, and Function Block Diagram for developing control applications.

- Configuration Tools: Includes intuitive tools for easy system setup and configuration of the MC-D5006-A module.

Diagnostic & Monitoring:

- Real-Time Monitoring: Continuous monitoring of system parameters to ensure optimal performance and reliability.

- Fault Diagnosis: Provides real-time fault diagnostics to alert operators of potential issues before they cause significant damage.

- Data Logging: Logs data for long-term analysis and troubleshooting.

Key Features & Benefits:

-

High-Performance Control:

- The MC-D5006-A offers fast processing for complex automation tasks, ensuring real-time control in critical industrial environments.

-

Redundancy & High Availability:

- Supports full system redundancy, ensuring that the system remains operational during faults or maintenance, which is vital in industries like oil and gas or power generation.

-

Scalable I/O System:

- Flexible I/O expansion options allow for easy scaling of the system as needs grow, supporting a wide range of devices and sensors.

-

Flexible Communication:

- Offers multiple communication options such as Ethernet/IP, Modbus TCP/IP, and Profibus, making it adaptable for integration with various devices and systems.

-

Built-in Diagnostics:

- Comprehensive diagnostic and fault detection capabilities reduce downtime and help operators maintain high system uptime.

-

Safety Standards Compliance:

- Meets important safety standards like SIL and IEC 61508, ensuring safe operation in industries with strict safety requirements.

-

Environmental Durability:

- Designed to perform in harsh industrial environments, the module is resistant to temperature extremes, humidity, and vibration.

-

Cost-Effective:

- Offers a cost-effective solution for high-reliability and high-performance control in automation systems.

Applications & Use Cases:

- Oil & Gas: Control of pumps, compressors, separators, and safety systems.

- Chemical Processing: Monitoring and control of reactors, mixers, and separation units.

- Power Generation: Automation of turbines, generators, and grid connection systems.

- Water Treatment: Control of water purification processes, chemical dosing, and monitoring of treatment plants.

- Manufacturing: Control of production lines, material handling, and machine automation.

Conclusion & Recommendation:

The RELIANCE MC-D5006-A DCS PLC Module is an advanced and flexible control solution for industrial automation, providing high-performance processing, robust redundancy features, and scalability. Its compatibility with various communication protocols, redundancy configurations, and environmental durability makes it well-suited for critical industries such as oil and gas, power generation, chemical, and manufacturing. Its diagnostic capabilities and safety standards compliance further ensure it is a reliable and effective choice for applications requiring continuous operation and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922